Materials Strategies for Advanced NanoTechnology

Kyung Choi

Nanotechnology, Bell Labs., Lucent Technologies, 600-700 Mountain Ave, Murray Hill,

NJ, 07974

We demonstrate ‘functional microfabrications’ by synthesizing new functional polymers.

Photopatternable silicon elastomers have been designed for high fidelity, functional

microfabrication purposes to integrate dynamic devices. ‘Elastic photopatterns’ generated

by using molecularly modified silicon elastomers have been demonstrated since

functional microfabrications are beneficial to develop elastic devices with high

resolutions for our diverse applications.

INTRODUCTION

Materials scientists and chemists have sought for the development of new materials and

novel microfabrication techniques to fabricate high performance devices.

1-7

We explored

novel materials strategies to bring new advances in nanotechnology by developing

functional polymers since nanotechnology is a part of chemical domain. We present

novel chemistry here to modify conventional silicon elastomers thus to extend current

nanotechnology to an advanced level for our diverse needs.

There are many promising technologies in nanotechnology such as soft lithography,

nanofabrications, functional pattern fabrications, and microfluidic technology. However,

commercial materials, which were developed for other purposes, often show limitations

for our specific purposes in nanotechnology. For this reason, we described here novel

chemical approaches to overcome the limitations in conventional materials thus to

achieve new advances in nanotechnology by developing new materials.

Soft lithography has been widely used to transfer small patterns from the masters to

substrates for integrating electronic patterns. Silicon elastomers are used for stamping or

microprinting purposes in pattern transfers. Sylgard 184 commercially produced from

Dow Corning, has been used in current soft lithography. However, those commercial

silicon rubbers often result in mechanical failures such as collapses, mergences, and

disconnections of features; especially, there are a lot of limitations for fabricating patterns

at the nano-scale regimes using Sylgard 184. Since it is beneficial for us to modify

chemical structures of commercial silicon rubbers, we introduced photopatternable

silicon rubbers in this study to satisfy our multiple demands. To overcome the limitations,

we designed and synthesized a new version of stamp materials.

Silicon rubbers are based on poly(dimethyl)siloxane network. Its highly elastic property

has been used for stamping and microfabrications.

Mater. Res. Soc. Symp. Proc. Vol. 1004 © 2007 Materials Research Society 1004-P06-08

Highly stretchable property of silicon elastomers is originated from the Si-O-Si structure

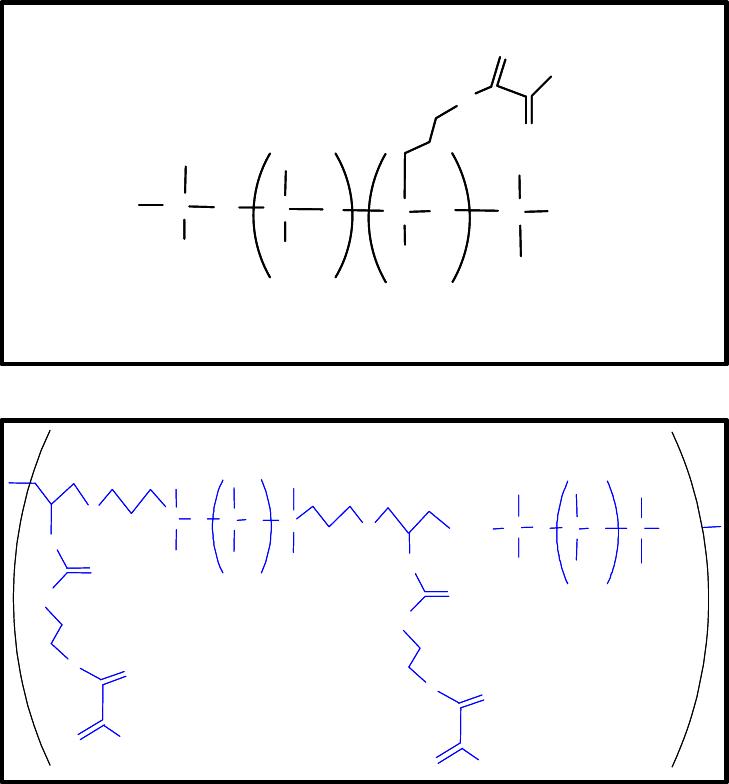

combined with cross-linked structure. Figure 1 illustrates a comparison of molecular

structures between conventional and designed photocurable PDMS prepolymers.

Figure 1. Chemical structures of (top) commercial photocurable and (bottom)

synthesized photocurable silicon rubbers.

Top of Figure 1 illustrates a chemical structure of a commercially available, photocurable

PDMS prepolymer; it is available from Gelest Inc. The bottom one shows a chemical

structure of synthesized, photocurable PDMS prepolymer. As shown in their structures,

both structures have photocurable methacrylate cross-linkers. However, the commercially

available silicon elastomer shown in Figure 1, revealed significant mechanical failures

during pattern transfers due to its low mechanical strength.

O

O

CH

3

Si

O

CH

3

CH

3

Si

CH

3

CH

3

CH

3

Si

CH

3

CH

3

O

Si

CH

3

O

e

f

Catalog #: Gelest, RMS-033

O

O

Si

O

CH

3

CH

3

Si

CH

3

CH

3

OSi

CH

3

CH

3

O

O

HN

O

CH

3

O(R) Si

O

CH

3

CH

3

Si

CH

3

CH

3

O

Si

CH

3

CH

3

(R)O

k

m

n

O

O

O

HN

O

CH

3

O

O

O

CH

3

Si

O

CH

3

CH

3

Si

CH

3

CH

3

CH

3

Si

CH

3

CH

3

O

Si

CH

3

O

e

f

Catalog #: Gelest, RMS-033

O

O

Si

O

CH

3

CH

3

Si

CH

3

CH

3

OSi

CH

3

CH

3

O

O

HN

O

CH

3

O(R) Si

O

CH

3

CH

3

Si

CH

3

CH

3

O

Si

CH

3

CH

3

(R)O

k

m

n

O

O

O

HN

O

CH

3

O

We thus modified the chemical structure of commercial silicon elastomers to achieve

enhanced mechanical stiffness since mechanical rigidity of stamp materials is

significantly related to the lithographic and patterning performances. As shown in Figure

1, the synthesized PDMS prepolymers have longer and stiffer cross-linkers compared to

that of the commercial one. The designed cross-linkers have produced a good mechanical

strength of synthesized PDMS during patterning transfers.

RESULTS AND DISCUSSION

We designed a new version of photocurable PDMS prepolymers by inserting novel

photocurable cross-linkers onto PDMS prepolymer networks. In order to improve

physical toughness of PDMS stamps, we provided new silicon elastomers with cross-

linkers containing urethane groups; because, urethane groups bring high mechanical

toughness to minimize mechanical collapses during lithographic and pattern transferring

tasks. The designed photocurable silicon prepolymer is denoted as hυ-PDMS

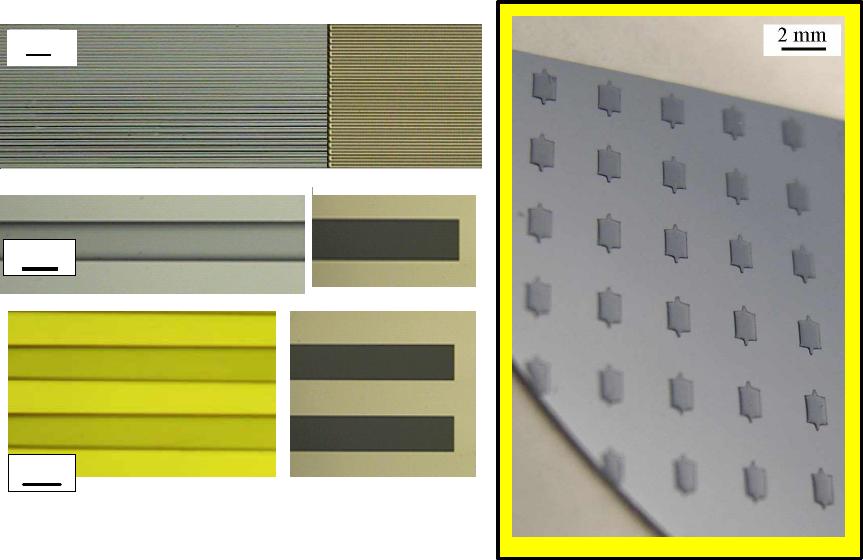

prepolymer. Figure 2 shows SEM images of the original master (submicron-scale features

of 300 nm line-width and 600 nm thickness) and the corresponding hυ-PDMS mold.

Figure 2. SEM images of the master and corresponding patterns transferred onto hυ-

PDMS mold.

Master

Mold (hυ-PDMS)

Master

Mold (hυ-PDMS)

Master

Mold (hυ-PDMS)

For elastic microfabrications of hυ-PDMS prepolymer, the hυ-PDMS prepolymer was

spin-coated on silicon wafers. Subsequently, original masks were placed on the hυ-

PDMS prepolymer layer, followed by UV exposure using a UVP Blak-Ray lamp at 365

nm for 1 min. It was then soaked into an ethanol bath for development. Microscopic

images of elastic microfabrications are shown in Figure 3.

Figure 3 shows microscopic images of various micro-features generated on silicon wafers

using hυ-PDMS prepolymer. Those patterns shown in Figure 3 are based on elastic

silicon rubbers in line-width size ranges of <100 µm, which weren’t easy to fabricate

using the commercial photocurable PDMS system.

As shown in Figure 3, performance of elastic photopatterning fabrications shows high

resolution with those micro-features. Modified PDMS prepolymers show the

improvements in functional microfabrications due to its adjustable mechanical stiffness.

We also carried out the microfabrications of elastic photopatterns in smaller sizes to

explore of pattern transfers using features in the smaller scale with 5µm-width striped

patterns. The result shows in the right frame of Figure 3.

As you can see in those images, hυ-PDMS prepolymers have produced ‘elastic

photopatterns’ with ~ 5 µm accuracy, which wasn’t be successful from commercial

photocurable PDMS prepolymers.

Figure 3. Elastic photopatterns generated on silicon wafer using hυ-PDMS prepolymer.

100 µm

Masters

Elastic photopatterns

100

µ

m100

µ

m

30

µ

m30

µ

m

100 µm

Masters

Elastic photopatterns

100

µ

m100

µ

m100

µ

m100

µ

m

30

µ

m30

µ

m30

µ

m30

µ

m30

µ

m

In conclusion, we demonstrate here a novel chemical strategy to synthesize stiffer,

photocurable PDMS prepolymers with adjustable mechanical strengths, that brings our

desired properties in materials for high fidelity soft lithography and functional

microfabrications in the submicron -scale regime for our diverse applications. We present

a specific advantage of the stiffer PDMS stamps, such as high resolution ‘elastic

photopatternability’. This result encourages us to develop new materials for

nanotechnology purposes.

REFERENCES

1. (a) E. Kim, Y. N. Xia, and G. M. Whitesides, J. Am. Chem. Soc. 118, 5722 (1996).

(b) Y. N. Xia, J. A. Rogers, K. E. Paul, and G. M. Whitesides, Chem. Rev. 99, 1823

(1999).

2. (a) K. M. Choi and J. A. Rogers, J. Am. Chem. Soc. 125, 4060 (2003).

(b) K. M. Choi, J. Phys. Chem. 109, 21525 (2005).

3. P. G. Conrad, P. T. Nishmura, D. Aherne, B. J. Schwartz, D. Wu, N. Fang, X. Zhang,

J. Roberts, K. J. Shea, Adv. Mater. 11, 5274 (2003).

4. T. Thorsen, S. J. Maerkl and S. R. Quake, Science 298, 580 (2002).

5. X. Duan, C. Niu, V. Sahi, J. Chen, J. W. Parce, S. Empedocles, J. L. Goldman,

Nature 425, 274 (2003).

6. T. Wu, Y. Mei, J. Cabral, C. Xu, K. L. Beers, J. Am. Chem. Soc. 126, 9880 (2004).

7. J. Kobayashi, Y. Mori, K. Okamoto, R. Akiyama, M. Ueno, T. Kitamori, S.

Kobayashi, Science 304, 1305 (2004).