http://journals.cambridge.org Downloaded: 22 Mar 2015 IP address: 138.251.14.35

Epitaxial growth and interfaces of high-quality InN films grown on

nitrided sapphire substrates

Fangliang Gao, Yunfang Guan, and Jingling Li

Department of Electronic Materials, State Key Laboratory of Luminescent Materials and Devices,

South China University of Technology, Guangzhou 510640, China

Junning Gao

State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China

Junqiu Guo and Guoqiang Li

a)

Department of Electronic Materials, State Key Laboratory of Luminescent Materials and Devices,

South China University of Technology, Guangzhou 510640, China

(Received 16 November 2012; accepted 26 February 2013)

InN films have been grown on sapphire substrates nitrided by N plasma with different durations

by radio-frequency plasma assisted molecular beam epitaxy (RF-MBE). In-depth investigation

reveals that AlN is generated on a sapphire surface during the nitridation, and 60 min nitridation

helps in the formation of an ordered and flat AlN interlayer between the substrate and the InN

film, which improves the surface migration of In atoms on the substrate, and consequently helps

in obtaining a single-crystalline c-plane InN film of high quality with 1.0 10

19

cm

3

carrier density

and 1350 cm

2

/(Vs) carrier mobility. Too short nitridation duration will result in a polycrystalline InN

film, and too long nitridation duration will damage the surface quality of the newly generated AlN

interlayer which consequently deteriorates the InN film quality. Control of the AlN interlayer quality

plays a critical role in the growth of a high-quality InN epitaxial film on the sapphire substrate.

I. INTRODUCTION

Indium nitride (InN) has attracted considerable attention

recently because of its outstanding electrical and optical

properties. Among III-nitride semiconductors, InN has

the lowest electron effective mass, the highest peak-drift

velocity and the highest peak overshoot velocity, which

are beneficial for high-electron-mobility transistors

(HEMTs).

1,2

Moreover, InN has a direct band gap of

;0.7 eV which enables the III-nitride s emiconductors

to cover the wave length from deep ultraviolet (AlN,

Eg 5 6.2 eV) to near infrared (InN, Eg 5 0.7 eV).

3,4

InN has

shown great potential in the fields of terahertz emitters,

5–8

light-emitting

9

and photovoltaic applications,

10

etc.

In 1972, Hovel and Cuomo

11

grew InN thin films on sap-

phire by using radio-frequency sputtering for the first time.

With the development of thin film growth technology,

researchers have obtained InN thin films using various

techniques, such as hydride vapor phase epitaxy (HVPE),

12

metal organic chemical vapor deposition (MOCVD),

13

radio frequency plasma assisted molecular-beam epitaxy

(RF-MBE),

14

pulsed laser deposition (PLD),

15,16

etc.

However, it is still difficult to obtain high-quality InN due

to its high equilibrium vapor pressure, low dissociation

temperature of nitrogen and the lack of suitable substrates

for InN.

17

To date, sapphire is the most common substrate to grow

III-nitride semiconductors. However, InN shares an up to

25% mismatch with sapphire in terms of lattice parameter

which results in polycrystalline InN films when directly

growing InN on sapphire. A large number of grain bound-

aries existing in polycrystalline InN films slow down trans-

portation of carriers. As a result, the performance of devices

is deteriorated. Consequently, single-crystalline InN films

are highly desired. If sapphire substrates are nitrided

before the growth of InN films, a thin nitrided layer might

be formed on the sapphire surface. This nitrided layer,

i.e., AlN interlayer, can act as a buffer between sapphire

and I nN. As pointed out, InN shares a lattice mismatch

of 25% and 13.9% with sapphire and AlN, respectively.

Therefore, the generation of an AlN interlayer on the

surface of a sapphire substrate dramatically decreases the

lattice mismatch between InN and sapphire. Meanwhile,

it should be noted that In atoms have strong adhesion on

sapphire substrates, which results in low lateral migration

and accumulation of In atoms on the sapphire surface,

leading to a rough surface of th e as-grown InN film.

The formation of an AlN interlayer on the other hand

prohibits the accumulation of In atoms on the sapphire

surface, so as to provide a smooth surface and a good

template for the succeeding InN epitaxial growth, which

plays an important role in improving the film quality of

a)

Address all correspondence to this author.

e-mail: [email protected]

DOI: 10.1557/jmr.2013.67

J. Mater. Res., Vol. 28, No. 9, May 14, 2013 Ó Materials Research Society 2013 1239

http://journals.cambridge.org Downloaded: 22 Mar 2015 IP address: 138.251.14.35

the as-grown InN film on sapphire. In this paper, we focus

on the influence of sapphire nitridation on the formation of

a nitrided interlayer, as well as its impact on the as-grown

InN film quality, and consequently propose an optimal

nitridation condition and its corresponding interlayer state

for high-quality InN films grown on sapphire substrates.

II. EXPER IMENTAL

InN films were grown by RF-MBE on (0001) sapphire

substrates. High purity indium (7N) and nitrogen gas (7N)

were used as the sources, respectively. Sapphire substrates

were degreased by organic solvents, etched in a hot so-

lution of H

2

SO

4

and H

3

PO

4

(H

2

SO

4

:H

3

PO

4

5 3:1) at

160 °C for 30 min, rinsed with deionized water, and finally

dried by 7N nitrogen before being put into the MBE load-

lock chamber with pressure 1 10

7

Torr. The substrates

were then transferred into the high vacuum MBE growth

chamber at pressure 1.0 10

10

Torr, and thermally

cleaned at 800 °C for 30 min to remove residual surface

contaminations. Before InN growth, the nitridation of

sapphire was carried out at 550 °C with a nitrogen flow

rate of 1 sccm and a RF plasma power of 240 W.

Subsequently, a low-temperature InN buffer layer was

grown at 350 °C for 5 min with a nitrogen flow rate of

2 sccm and a RF plasma power of 400 W. In the end, a

high-temperature InN layer was grown at 550 °C for

60 min with a nitrogen flow rate of 2 sccm and a RF plasma

power of 240 W. A quartz crystal microbalance (QCM)

was used to monitor the deposition rate during the growth.

It reveals that the thicknesses for the low- and the high-

temperature InN layers are 10 and 200 nm, respectively.

The as-grown InN films were evaluated by x-ray diffraction

(XRD, with Cu K

a1

as an x-ray source) for crystallinity by

Bruker D8 Discover. Cross-sectional high resolution trans-

mission electron microscopy (HRTEM) was carried out to

study the interfaces between the substrates and InN films.

The HRTEM samples were put into a JEOL 3000F field

emission gun TEM (Tokyo, Japan) working at a voltage of

300 kV, which gives a point to point resolution of 0.17 nm.

Electron energy loss spectroscopy (EELS) collections were

carried out under scanning TEM mode, where a spot

formed by a 0.6 nm diameter electron beam was used to

scan across the interface with an interval of 1 nm between

two spots. Scanning electron microscopy (SEM) was then

carried out to evaluate the microstructure of InN films by

FEI Nova NanoSEM 430 (Hillsboro, OR). Hall effect

measurements were also performed at room temperature

to obtain carrier characteristics with a 3000 Gauss magnet.

III. RESULTS AND DISCUSSION

Figure 1 shows the XRD patterns for InN films grown

on (0001) sapphire nitrided with different durations of 20,

30, 50, 60, and 120 min, respectively. Peaks located at

31.02 and 64.66° are from hexagonal InN (0002) and (0004)

planes, those at 33.0 and 69.22° are from InN (10-11) and

(20-22) planes, and the one at 41.6° is from sapphire (0006)

plane. Apparently, InN films grown on sapphire substrates

with nitridation durations of 20, 30, and 50 min are poly-

crystalline with two growth directions of ,0001. (c axis)

and ,10-11., while InN films grown on sapphire sub-

strates with nitridation durations of 60 and 120 min a re

single-crystalline with c axis as the growth direction.

This indicates that the nitridation duration of the sapphire

substrate plays a critical role in determining the crystal-

line form and the growth direction of as-grown InN films.

Too short nitridation duration of sapphire substrates leads

to polycrystalline InN films, while a nitridation duration

of longer than 60 min helps to obtain single-crystalline

InN films on sapphire substrates.

To better understand this finding, HRTEM is carried

out to study the interface between the sapphire substrate

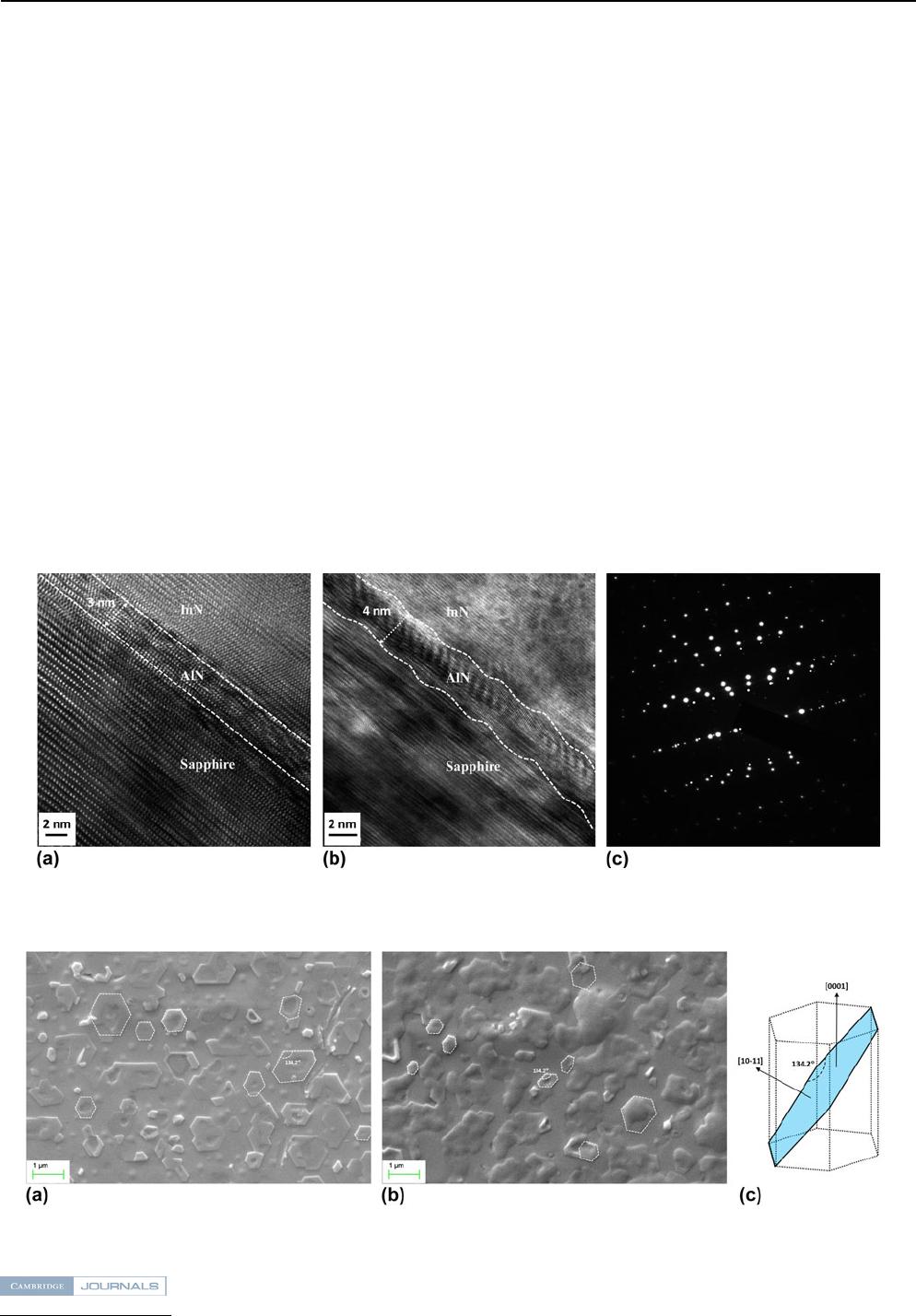

and the InN epitaxial film. Figure 2(a) is the HRTEM

image for an InN sample with 60 min nitridation. One can

clearly notice a continuous interlayer with the thickness of

;3 nm between the sapphire substrate and the InN epi-

taxial film. This continuous interlayer is very flat and

ordered, as illustrated by the two parallel dotted lines in

Fig. 2(a). The concentration of this interlayer has also been

characterized by EELS attached to this TEM. It reveals

that only Al and N are contained in this interlayer, and no

trace of O is detected. EELS measurement further reveals

that the atomic ratio between Al and N is 1, or equally,

AlN. It suggests that the following reaction take places

when sapphire substrates are nitrided by N plasma at high

temperature,

Al

2

O

3

þNðplamsaÞ!AlN þ N

x

O

y

: ð1Þ

The newly generated N

x

O

y

is in the gaseous state and

will be exhausted by the MBE pumping system, leaving a

FIG. 1. XRD patterns of the InN films grown on (0001) sapphire

substrates with various nitridation durations.

F. Gao et al.: Epitaxial growth and interfaces of high-quality InN films grown on nitrided sapphire substrates

J. Mater. Res., Vol. 28, No. 9, May 14, 20131240

http://journals.cambridge.org Downloaded: 22 Mar 2015 IP address: 138.251.14.35

fresh AlN surface on the sapphire substrate. Selected area

electron diffraction around this interface by TEM is given

in Fig. 2(c). Careful investigation lets us to spot three

groups of diffractions, from sapphire, AlN, and InN, re-

spectively. It once again confirms the existence of the AlN

interlayer.

Interestingly, further increase in nitridation duration will

lead to a poorer-quality interlayer, as shown in Fig. 2(b),

the cross-sectional HRTEM image of an InN sample with

120 min nitridation. The thickness of the interlayer with

120 min nitridation is ;4 nm, which is only slightly thicker,

other than 2 times thicker considering the nitridation dura-

tion, than that after 60 min nitridation. It suggests that after

a continuous AlN interlayer is formed following 60 min

nitridation, it becomes much more difficult for N plasma

to diffuse and penetrate the interlayer and react with the

internal sapphire. More important information we get from

Fig. 2(b) is that the interlayer with 120 min nitridation

becomes very wavy and rough, and also much more stressed

and disordered when compared with the straight and smooth

interlayer surface with 60 min nitridation. This wavy and

rough AlN interlayer undoubtably has a negative impact on

the surface migration of In atoms on the substrate surface,

which deteriorates the quality of the subsequently grown

InN film that has been verified by our Hall effect mea-

surement of the samples as discussed later. TEM findings

suggest that too long exposure to the highly energetic N

plasma will damage the surface of the interlayer and hence

the as-grown InN film quality, which is consistent with our

SEM observation.

The surface morphology of the as-grown InN films is

characterized by SEM. Figures 3(a) and 3(b) show those

with nitridation duration of 20 and 30 min, respectively.

We note that both samples share a similarly rough mor-

phology. Apart from those coalesced or overlapped grains,

we can also clearly notice two types of grains with dif-

ferent shapes, as representatively stand out in the images.

Bear in mind that XRD measurement has revealed that

both the films will have two growth directions, i.e., ,00 01.

and ,10-11.. As a reference, we schematically illustrate

these two growth directions and their corresponding planes

in the InN’s wurtzite structure, Fig. 3(c), only to find out the

shapes of the two types of grains match perfectly with the

{0001} and {10-11} planes, respectively. We can then

FIG. 2. (a) Cross-sectional HRTEM images around the interface between the sapphire substrate and the InN film with (a) 60 min and (b) 120 min

nitridations, and (c) the corresponding selected area electron diffraction pattern of (a), where 3 groups of patterns could be spotted.

FIG. 3. SEM images of InN films grown on sapphire substrates nitrided for (a) 20 min and (b) 30 min, respectively, and (c) the schematic illustration

of a InN’s wurtzite structure as well as its two growth directions of ,0001. and ,10-11..

F. Gao et al.: Epitaxial growth and interfaces of high-quality InN films grown on nitrided sapphire substrates

J. Mater. Res., Vol. 28, No. 9, May 14, 2013 1241

http://journals.cambridge.org Downloaded: 22 Mar 2015 IP address: 138.251.14.35

deduce that those of regular hexagonal shapes are from InN

grown along the ,0001. direction, and those of irregular

hexagonal shapes are from InN grown along the ,10-11.

direction. The sizes of two types of grains are within the

same range, from ;0.5 to 1.0 lm, and the proportion of

the two types of grains are almost the same. A further in-

crease in nitridation duration of the sapphire substrates up

to 50 min will not change the surface morphologies of InN

films, which has been confirmed by SEM observation.

Obviously, under this polycrystalline growth condition with

nitridation duration no longer than 50 min, the two types of

grains share the same growth opportunity and no one will

prevail over the other.

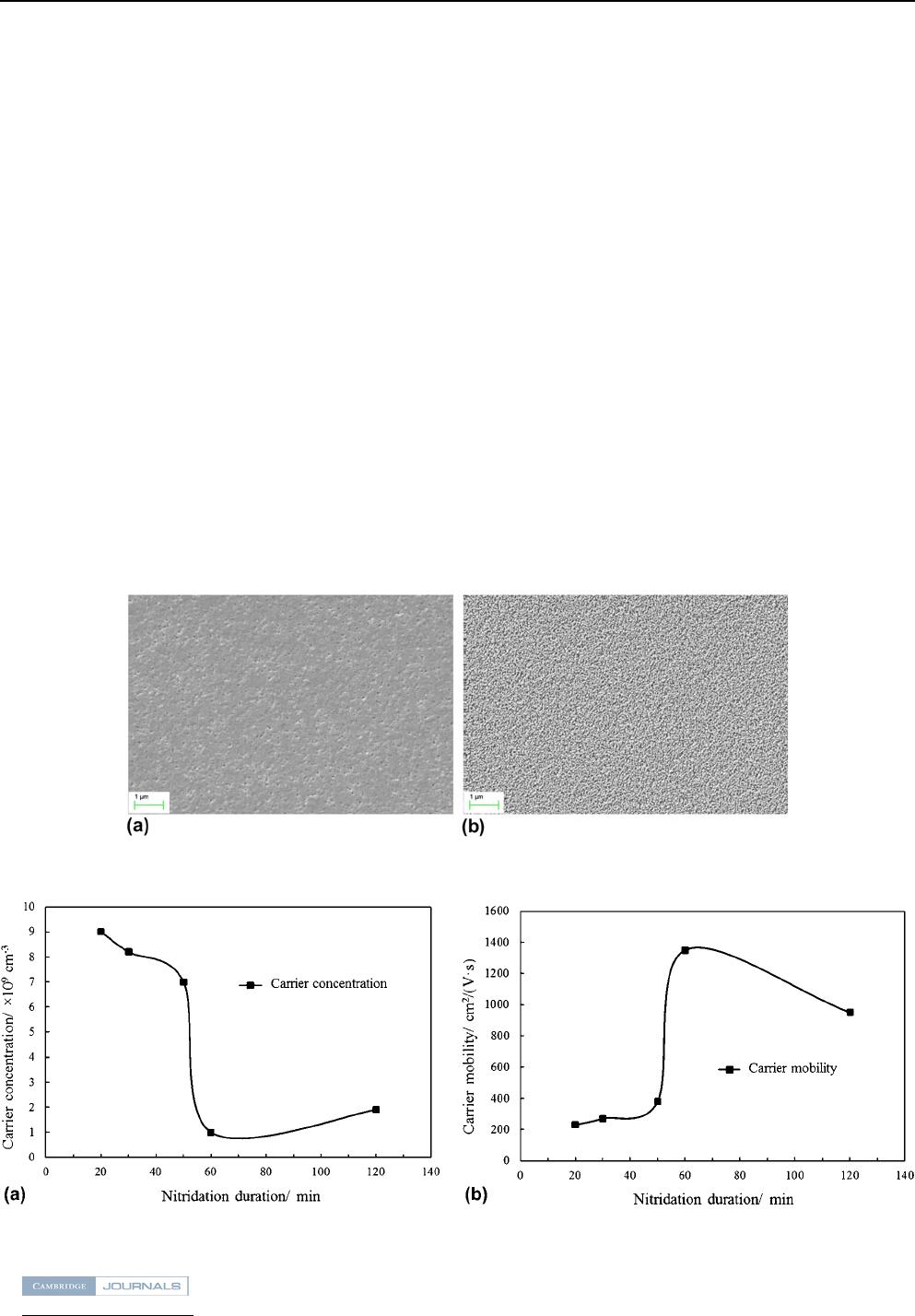

Figure 4(a) shows the SEM image of an InN film grown

on a sapphire substrate nitrided for 60 min. Different from

InN films with less than 50 min nitridation, this film con-

tains grains only of ,0001. growth direction. These grains

coalesce to each other very well, leading to a much flatter

surface than those polycrystalline films. Figure 4(b) shows

the SEM image of an InN film grown on a sapphire sub-

strate nitrided for 120 min. Surprisingly, this film exhibits

much smaller uncoalesced grains and a much rougher sur-

face when compared with the InN film nitrided for 60 min,

although both films are single-crystalline. Obviously, a too

long nitridation duration actually damages the film quality

of the as-grown InN film.

Room-temperature Hall effect measurement has been

carried out with a 3000 Gauss magnet to characterize the

carrier transportation properties of the as-grown InN films.

For this purpose, samples were cut into 10 10 mm

2

and

In foil was pressed on to form the van der Pauw configura-

tion with Ohmic contacts. As we know, InN has a very large

electron affinity.

18–20

Therefore, it is not surprising that

all of our as-grown undo ped InN films exhibit n-type

conductivity, due to the pinning of the Fermi level above

the conduction band edge. Figure 5(a) shows the carrier

concentration for the as-grown samples as a function of

nitridation duration. We find that polycrystalline InN

films have much higher carrier concentration than single-

crystalline InN, which we attribute to the defects in poly-

crystalline films due to the poor surface migration of In

atoms on sapphire substrates.

21

Among polycrystalline

InN samples with nitridation duration no longer than

50 min, the increment in nitridation duration slightly de-

creases the carrier concentration, implying some more AlN

islands formed on sapphire substrates which enhances the

surface migration of In atoms and hence the film quality.

A steep drop in carrier concentration takes place at 60 min

FIG. 4. SEM images of InN films grown on sapphire substrates nitrided for (a) 60 min and (b) 120 min.

FIG. 5. Room-temperature Hall effect measurement of as-grown InN films with various nitridation durations. (a) Carrier concentration, and

(b) carrier mobility.

F. Gao et al.: Epitaxial growth and interfaces of high-quality InN films grown on nitrided sapphire substrates

J. Mater. Res., Vol. 28, No. 9, May 14, 20131242

http://journals.cambridge.org Downloaded: 22 Mar 2015 IP address: 138.251.14.35

nitridation, from 5.5 10

19

to 1.0 10

19

cm

3

, which in-

dicates a very high quality InN film. This is because of the

formation of the continuous AlN interlayer, and conse-

quently the dramatically improved surface migration of In

atoms on the substrate. However, a further increment in

nitridation duration will raise the carrier concentration,

Fig. 5(a), from 1.0 10

19

to 1.9 10

19

cm

3

, indicating a

worsen InN film quality. As discussed above, we attribute

this to the roughened surface of the AlN interlayer due to

too long bombarding by highly energetic N plasma, which

decreases In atom surface migration.

Figure 5(b) shows the carrier mobility for the as-grown

samples as a function of nitridation duration. The as-grown

InN films grown with nitridation durations of 20, 30, 50, 60,

and 120 min have a carrier mobility of 230, 270, 380, 1350,

and 950 cm

2

/(Vs), respectively. Similar to what happens

to the carrier concentration, polycrystalline InN samples

with nitridation duration no longer than 50 min show very

poor carrier mobility of less than 400 cm

2

/(Vs), and single-

crystalline InN samples with 60 min nitridation show very

high film quality with carrier mobility up to 1350 cm

2

/(Vs).

Likewise, further increases in nitridation duration up to

120 min will damage the AlN interlayer quality, which

appears as a diminishing carrier mobility of 950 cm

2

/(Vs).

The results from Hall effect measurement once again con-

firm the importance of an optimal nitridation duration of

sapphire substrates to the as-grown InN film quality. In other

words, 60 min nitridation brings up with a smooth and or-

dered AlN interlayer on top of sapphire which improves the

surface migration of In atoms in InN films, and consequently

enhances carrier properties.

It is not hard to understand that there is an optimal

value for the nitridation duration. Too short nitridation

duration will be not enough to form a continuous AlN layer

on the sapphire surface, and a proportion of sapphire sur-

face is still exposed to In atoms during the growth where

In atoms will unavoidably accumulate. Under such a circum-

stance, as-grown InN films will be polycrystalline with a

rough surface. On the contrary, if nitridation duration is

long enough (up to 60 min), a continuous AlN interlayer

can fully cover the sapphire surface. In atoms obtain much

better migration ability on AlN. Moreover, InN shares much

smaller in-plane lattice mismatch with AlN. The epitaxial

growth condition along c axis for the InN film has therefore

been achieved. Accordingly, a single-crystalline InN film is

grown. If a nitridation duration longer than 60 min is applied

to sapphire substrates, the newly formed continuous AlN

interlayer will be enduring too long bombarding by the

highly energetic N plasma which damages the surface of the

interlayer, resulting in a decrease in InN film quality.

IV. CONCLUSIONS

InN films have been grown on sapphire substrates nitrided

with different durations by RF-MBE. It is found that

nitridation duration of the sapphire substrates determines

the as-grown film quality. Nitridation duration of no longer

than 50 min will end up with a polycrystalline InN film

with two growth directions of ,0001. and ,10-11.,

while nitridation duration of 60 min will bring up with

a single-crystalline c -plane InN film of high quality with

1.0 10

19

cm

3

carrier density and 1350 cm

2

/(Vs) carrier

mobility. However, a further increment in nitridation

duration will worsen the as-grown quality though it is still

single-crystalline.

EELS analysis on the interlayer between the InN film and

the nitrided sapphire substrate by cross-sectional HRTEM

reveal that AlN is generated on the sapphire surface during

the nitridation by N plasma, and 60 min nitridation leads

to a continuously straight and smooth AlN interlayer of

;3 nm which enormously enhances the surface migration

of In atoms on the substrate, resulting in a high-quality

single-crystalline InN film with excellent carrier proper-

ties. Too short nitridation duration of no more than 50 min

will be not enough to form a continuous AlN layer on the

sapphire surface, and a proportion of the sapphire surface

is still exposed to In atoms during the growth where In

atoms will unavoidably accumulate. That’s the reason why

a polycrystalline InN film is obtained. On the other hand,

if a nitridation duration of longer than 60 min is applied

to sapphire substrates, the newly formed continuous AlN

interlayer will be enduring too long bombarding by the

highly energetic N plasma which damages the surface of

the interlayer, resulting in a decrease in InN film quality.

To conclude, it is the right optimal nitridation duration

that helps to form an ordered and flat AlN interlayer between

the substrate and the InN film, which improves the surface

migration on In atoms on the substrate, and consequently

helps to obtain a high-quality InN film.

ACKNOWLEDGMENTS

This work is supported by National Science Foundation

of China (Contract No. 51002052), and Key Project in

Science and Technology of Guangdong Province (Contract

No. 2011A080801018).

REFERENCES

1. S.P. Fu and Y.F. Chen: Effective mass of InN epilayers. Appl. Phys.

Lett. 85, 1523 (2004).

2. V.M. Polyakov and F. Schwierz: Low-field electron mobility in

wurtzite InN. Appl. Phys. Lett. 88, 032101 (2006).

3. C.A. Hurni, S. Choi, O. Bierwagen, and J.S. Speck: Coupling

resistance between n-type surface accumulation layer and p-type

bulk in InN: Mg thin films. Appl. Phys. Lett. 100, 082106 (2012).

4. A. Knuumlbel, R. Aidam, V. Cimalla, L. Kirste, M. Baeumler,

C.C. Leancu, V. Lebedev, J. Wallauer, M. Walther, and J. Wagner:

Transport characteristics of indium nitride (InN) films grown by

plasma assisted molecular beam epitaxy (PAMBE). Phys. Status

Solidi C 6, 1480 (2009).

5. J-S. Hwang, J-T. Tsai, K-I. Lin, M-H. Lee, C-N. Tsai, H-W. Lin,

S. Gwo, and M-C. Chen: Terahertz radiation mechanism of native

F. Gao et al.: Epitaxial growth and interfaces of high-quality InN films grown on nitrided sapphire substrates

J. Mater. Res., Vol. 28, No. 9, May 14, 2013 1243

http://journals.cambridge.org Downloaded: 22 Mar 2015 IP address: 138.251.14.35

n-type InN with different carrier concentrations. Appl. Phys.

Express 3, 102202 (2010).

6. G.D. Metcalfe, H. Shen, M. Wraback, G. Koblmueller, C. Gallinat,

F. Wu, and J.S. Speck: Terahertz radiation from nonpolar InN due

to drift in an intrinsic In-plane electric field. Appl. Phys. Express 3,

092201 (2010).

7. H. Ahn, Y.J. Yeh, Y.L. Hong, and S. Gwo: Terahertz emission

mechanism of magnesium doped indium nitride. Appl. Phys. Lett.

95, 232104 (2009).

8. X.Q. Wang, G.Z. Zhao, Q. Zhang, Y. Ishitani, A. Yoshikawa, and

B. Shen: Effect of Mg doping on enhancement of terahertz emission

from InN with different lattice polarities. Appl. Phys. Lett. 96,061907

(2010).

9. A. Hangleiter: III-V nitrides: A new age for optoelectropics. MRS

Bull. 28, 350 (2003).

10. E. Trybus, G. Namkoong, W. Henderson, S. Burnham, W.A. Doolittle,

M. Cheung, and A. Cartwright: InN: A material with photovoltaic

promise and challenges. J. Cryst. Growth 288, 218 (200 6).

11. H.J. Hovel and J.J. Cuomo: Electrical and optical properties or

rf-sputtered GaN and InN. Appl. Phys. Lett. 20, 71 (1972).

12. D.Y. Song, V. Kuryatkov, M. Basavaraj, D. Rosenbladt, S.A. Nikishin,

M. Holtz, A.L. Syrkin, A.S. Usikov, V.A. Ivantsov, and V.A. Dmitriev:

Morphological, electrical, and optical properties of InN grown by

hydride vapor phase epitaxy on sapphire and template substrates.

J. Appl. Phys. 99, 116103 (2006).

13. C. Rauch, O. Tuna, C. Giesen, M. Heuken, and F. Tuomisto: Point

defect evolution in low-temperature MOCVD growth of InN. Phys.

Status Solidi A 209, 87 (2012).

14. J. Kuyyalil, M. Tangi, and S.M. Shivaprasad: Dependence of crystal

orientation and bandgap on substrate temperature of molecular-beam

epitaxy grown InN on bare Al

2

O

3

(0001). J. Appl. Phys. 109,093513

(2011).

15. F. Stokker-Cheregi, A. Nedelcea, M . Filipescu, A. Moldovan,

D. Colceag, V. Ion, R. Birjega, and M. D inescu: High tem-

perature growth of InN on various substrates by plasma-

assisted pulsed laser deposition. Appl. Surf. Sci. 257, 5 312

(2011).

16. G. Li and H. Yang: Epitaxial growth of high quality nonpolar

InN films on LiG aO

2

substrates. Cryst. G rowth Des. 11,664

(2011).

17. Q. Huang, S. Li, D. Cai, and J. Kang: Kinetic behavior of nitrogen

penetration into indium double layer improving the smoothness of

InN film. J. Appl. Phys. 111, 113528 (2012).

18. H. Lu, W.J. Schaff, L.F. Eastman, and C.E. Stutz: Surface charge

accumulation of InN films grown by molecular-beam epitaxy. Appl.

Phys. Lett. 82, 1736 (2003).

19. A.A. Klochikhin, V.Y. Davydov, I.Y. Strashkova, and S. Gwo:

Classical and quantum solutions of the planar accumulation layer

problem within the parabolic effective-mass approximation. Phys.

Rev. B 76, 235325 (2007).

20. I. Mahboob, T.D. Veal, C.F. McConville, H. Lu, and W.J. Schaff:

Intrinsic electron accumulation at clean InN surfaces. Phys. Rev.

Lett. 92, 036804 (2004).

21. A.G. Bhuiyan, A. Hashimoto, and A. Yamamoto: Indium nitride

(InN): A review on growth, characterization, and properties. J. Appl.

Phys. 94,2779(2003).

F. Gao et al.: Epitaxial growth and interfaces of high-quality InN films grown on nitrided sapphire substrates

J. Mater. Res., Vol. 28, No. 9, May 14, 20131244