Experimental Liquidus Surface Projection

and Thermodynamic Modeling of the Fe-Mo-Nb

System

LEI ZOU, CUIPING GUO, CHANGRONG LI, and ZHENMIN DU

The liquidus surface projection of the Fe-Mo-Nb ternary system was constructed by means of

X-ray diffraction, scanning electron microscopy coupled with energy dispersive X-ray

spectroscopy, and differential thermal analysis. The experimental results indicate that the

liquidus surface projection consists of six primary soli dification regions and four ternary

invariant reactions. On the basis of the experimental results in the present work and isothermal

sections taken from the literature, the Fe-Mo-Nb system is modeled using the CALculation of

PHAse Diagram (CALPHAD) method. Solution phases, liquid, bcc, and fcc, are treated as the

substitutional solution. The l and Fe

2

(Mo, Nb) phases are treated as (Fe, Mo, Nb)

1

(Mo,

Nb)

4

(Fe, Mo, Nb)

2

(Fe, Mo, Nb)

6

and (Fe, Mo, Nb)

2

(Fe, Mo, Nb)

1

using the sublattice model,

respectively. A set of self-consistent thermodynamic parameters is thus obtained. The

experimental liquidus surface projection and isothermal sections at 900 C, 1100 C, and

1200 C are reproduced using the present thermodynamic description.

https://doi.org/10.1007/s11661-019-05254-5

The Minerals, Metals & Materials Society and ASM International 2019

I. INTRODUCTION

IN recent years, demand has increased for a broad

range of structural materials that are environmen tally

benign, energy efficient, light weight, and reliable in

design.

[1–3]

The next generation of high-pe rformance

structural materials, such as ultrastrong steel, must have

high strength/weight ratios, good fracture toughness,

and good joining capabilities.

[3]

The addition of molybdenum and niobium to steel

can effectively improve its strength and toughness.

[4,5]

Mo and Nb are strong carbide-forming elements in steel.

The carbides thus produced can obs truct the motion of

dislocations and prevent austenite grain growth during

austenization.

[4–10]

However, the addition of high con-

centrations of Mo can stabilize the r phase.

[11,12]

This

phase is extremely brittle, which leads to the formation

of cracks and causes the toughness of the steel to

deteriorate.

Phase diagrams provide the basic data needed when

designing material compositions and heat treatment

processes. Thus, it is impor tant to obtain the ternary

phase diagram for the Fe-Mo-Nb system to ensure the

correct development and design of new generations of

high-performance steels.

II. LITERATURE INFORMATION

A. Binary Systems

Based on experimental data,

[13–20]

the Fe-Mo system

has been thermodynamically optimized by several

researchers.

[12,21–25]

The system has been subsequently

reassessed by Rajkumar and Kumar

[26]

based on their

experimental results and ab initio calculations . There-

fore, the updated thermodynamic description of the

Fe-Mo system provided by Rajkumar and Kumar

[26]

is

the one used in the present work.

The Fe-Nb system has also been optimized by many

researchers

[27–33]

based on the available experimental

investigations.

[34–40]

The optimization results of Jacob

et al.

[31]

were adopted by Guo et al.

[41]

and Stein et al.,

[42]

and the thermodynamic parameters from Reference 31

are also adopted in this work.

The Mo-Nb system has been optimized by Xiong

et al.

[43]

based on the experimental data obtained by

Kocherzhinskii and Vasilenko,

[44]

and their results are

the one adopted in this work.

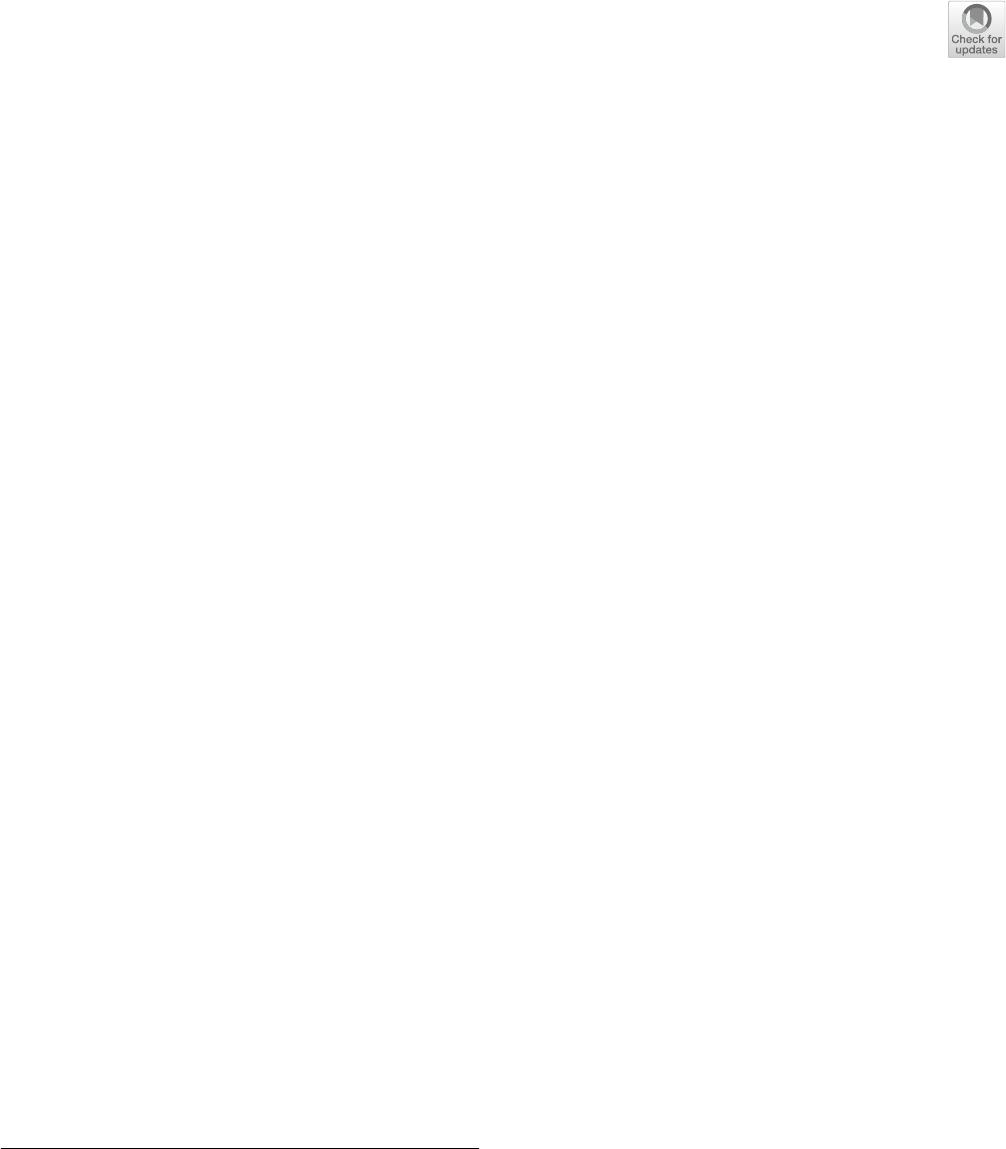

The calculated Fe-Mo,

[26]

Fe-Nb,

[31]

and Mo-Nb

[43]

phase diagrams are shown in Figure 1.

LEI ZOU, CUIPING GUO, CHANGRONG LI, and ZHENMIN

DU are with the School of Materials Science and Engineering,

University of Science and Technology Beijing, Beijing 100083, P.R.

Manuscript submitted November 20, 2018.

Article published online May 3, 2019

3358—VOLUME 50A, JULY 2019 METALLURGICAL AND MATERIALS TRANSACTIONS A

B. Fe-Mo-Nb Ternary System

The first complete isothermal section at 900 C was

determined by Smirnova et al.,

[45]

and two three-phase

regions were constructed. The solubi lities of Mo in

l-Fe

7

Nb

6

and Nb in l-Fe

7

Mo

6

at 900 C were found to

be about 5 and 10 at. pct, respectively. Later on, the

Fe-rich (> 96 at. pct Fe) corners of the isothermal

sections at 950 C, 1050 C, 1150 C, and 1250 Cin

the Fe-Mo-Nb system were presented by Kumar and

Raghavan.

[46]

Recently, in some of our previous work, isothermal

sections at 1100 C and 1200 C were measured by

scanning electron microscopy coupled with energy

dispersive X-ray spectroscopy (SEM-EDS) and X-ray

diffraction (XRD).

[47]

It was found that there are four

three-phase regions in the isothermal section at 11 00 C

and three three-phase regions in the isothermal section

at 1200 C. The maximum solubilities of Mo in Fe

2

Nb

and l-Fe

7

Nb

6

, and Nb in l-Fe

7

Mo

6

were determined to

be about 26.97, 7.35, and 19.74 at. pct at 1100 C,

respectively. The corresponding maximum solubilities at

1200 C were determined to be about 25.08, 10.40, and

23.85 at. pct, respectively.

The main purpose of this work is to present the

self-consistent thermodynamic parameters for the indi-

vidual phases of the Fe-Mo-Nb system using the

CALPHAD (CALculation of PHAse Diagram) method.

Thermodynamic optimization is carried out based on

experiments. Due to a lack of experimental data related

to the liquid phases, the experimental liquidus surface

projection was determined by means of SEM-EDS,

XRD, and differential thermal analysis (DTA). The

liquidus surface projection constructed in the present

work an d the isothermal sections

[47]

help improve the

reliability of the available thermodynamic parameters.

Fig. 1—Calculated binary phase diagrams: (a) Fe–Mo

[26]

;(b) Fe–Nb

[31]

;(c) Mo–Nb

[43]

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 50A, JULY 2019—3359

III. EXPERIMENTAL PROCEDURES

High-purity starting materials were used to prepare

the ternary alloy samples in form of Fe bulk

(99.99 wt pct), Mo rods (99.99 wt pct), and Nb rods

(99.99 wt pct), in the present work. All samples were

prepared by arc-melting them under an argon atmo-

sphere of high purity. The arc furnace chamber was first

evacuated and flushed with pure Ar at least four times.

Then, a piece of pure Ti was re-melted at least three

times before alloying in order to consume any residual

oxygen. To ensure composition homogeneity, all sam-

ples were inverted and re-melted at least five times. The

ingots whose burning losses did not exceed 0.5 wt pct

were chosen to use in the subsequent experiments.

The as-cast microstructures and composition analyses

were carri ed out using a commercially available SEM

(LEO-1450, Zeiss, Germany) coupled with an EDS

(NORAN-7, Thermo Scientific, USA). An acceleration

voltage of 20 kV was employed. Composition measure-

ments were co nducted at least three times. The XRD

measurements were carried out using a diffractometer

(SmartLab, Rigaku, Japan) employing Cu-Ka radiation

(k = 1.5406 A

˚

) at 40kV and 150 mA. Diffraction spec-

tra were collected between 10 and 100 deg with a scan

step size of 0.02 deg.

The phase transformation temperatures at the Fe-rich

corner were determined by a DTA (SDT-Q600, TA Instru-

ments, USA) using Al

2

O

3

crucibles. The DTA measurements

were performed with heating rate of 10 Cmin

1

.

IV. THERMODYNAMIC OPTIMIZATION

A. Thermodynamic Model for Substitutional Phases

In the present work, Gibbs energy functions for the

unary phases (elemental Fe, Mo, and Nb) are taken

from the Scientific Group Thermodata Europe database

of pure elements compiled by Dinsdale.

[48]

In the Fe-Mo-Nb system, there are three solution

phases, liquid, fcc, and bcc. Their molar Gibbs energies

are described by the following expression:

G

/

m

ðTÞ¼x

Fe

G

/

Fe

ðTÞþx

Mo

G

/

Mo

ðTÞþx

Nb

G

/

Nb

ðTÞ

þ RTðx

Fe

ln x

Fe

þ x

Mo

ln x

Mo

þ x

Nb

ln x

Nb

Þ

þ

E

G

/

m

þ

mg

G

/

m

;

½1

where x

Fe

, x

Mo

, and x

Nb

are mole fractions of the pure

elements Fe, Mo, and Nb, respectively;

mg

G

/

m

is the

magnetic contribution to the free energy (vide infra)

and

E

G

/

m

is the excess Gibbs energy, which can be

expressed in the form of a Redlich–Kister polyn omial,

E

G

/

m

¼ x

Fe

x

Mo

X

n

n

L

/

Fe;Mo

ðx

Fe

x

Mo

Þ

n

þ x

Fe

x

Nb

X

n

n

L

/

Fe;Nb

ðx

Fe

x

Nb

Þ

n

þ x

Mo

x

Nb

X

n

n

L

/

Mo;Nb

ðx

Mo

x

Nb

Þ

n

þ x

Fe

x

Mo

x

Nb

L

/

Fe;Mo;Nb

; ½2

where

n

L

/

Fe;Mo

,

n

L

/

Fe;Nb

, and

n

L

/

Mo;Nb

are the nth inter-

action parameters between elements Fe and Mo, Fe and

Nb, and Mo an d Nb, respectively, which can be taken

from References 26, 31, and 43. L

/

Fe;Mo;Nb

is the ternary

interaction parameter which we express in the form:

L

/

Fe;Mo;Nb

¼ x

Fe

0

L

/

Fe;Mo;Nb

þ x

Mo

1

L

/

Fe;Mo;Nb

þ x

Nb

2

L

/

Fe;Mo;Nb

; ½3

where

n

L

/

Fe;Mo;Nb

are the parameters to be optimized in

the present work.

In the Fe-Mo and Fe-Nb systems, there is a magnetic

contribution to the Gibbs energy in the fcc and bcc

phases. The model of magnetic contribution to the

Gibbs energy

mg

G

/

m

was proposed by Inden

[49]

and

modified by Hillert and Jarl,

[50]

and

mg

G

/

m

is expressed as

follows:

mg

G

/

m

¼ RTIn b þ 1ðÞf sðÞ; ½4

where f sðÞis the polynomial function obtained by Hil-

lert and Jarl

[50]

based on the magnetic specific heat of

iron which is defined in terms of s = T/T

c

where T

c

is

the Curie temperature, and b is the average atomic

magnetic moment (set equal to the molar Bohr mag-

netic moment). The parameters T

c

and b can be

described using the following expressions:

T

/

c

¼ x

Fe

T

/

cFe

þ x

Mo

T

/

cMo

þ x

Nb

T

/

cNb

þ x

Fe

x

Mo

X

n

n

T

/

cFe;Mo

ðx

Fe

x

Mo

Þ

n

þ x

Fe

x

Nb

X

n

n

T

/

cFe;Nb

ðx

Fe

x

Nb

Þ

n

þ x

Mo

x

Nb

X

n

n

T

/

cMo;Nb

ðx

Mo

x

Nb

Þ

n

þ x

Fe

x

Mo

x

Nb

T

/

cFe;Mo;Nb

½5

b

/

¼ x

Fe

b

/

Fe

þ x

Mo

b

/

Mo

þ x

Nb

b

/

Nb

þ x

Fe

x

Mo

X

n

n

b

/

Fe;Mo

ðx

Fe

x

Mo

Þ

n

þ x

Fe

x

Nb

X

n

n

b

/

Fe;Nb

ðx

Fe

x

Nb

Þ

n

þ x

Mo

x

Nb

X

n

n

b

/

Mo;Nb

ðx

Mo

x

Nb

Þ

n

þ x

Fe

x

Mo

x

Nb

b

/

Fe;Mo;Nb

; ½6

where T

/

c

and b

/

are the corresponding magnetic

parameters of pure elements Fe, Mo, and Nb;

n

T

/

c;

and

n

b

/

;

are the nth binary magnetic interaction parameters;

T

/

cFe;Mo;Nb

and b

/

Fe;Mo;Nb

are the ternary magnetic inter-

action parameters. All the magnetic parameters except

T

/

cFe

and b

/

Fe

were set to zero due to a lack of

experimental data on the magnetic properties of the

binary and ternary bcc and fcc solutions.

3360—VOLUME 50A, JULY 2019 METALLURGICAL AND MATERIALS TRANSACTIONS A

B. Thermodynamic Model for Intermetallic Phases

The tw o intermetallic compounds Fe

2

Mo and Fe

2

Nb

are treated as one phase and referred to as Fe

2

(Mo, Nb)

because they have same crystal structure (that of

MgZn

2

). Similarly, the l-Fe

7

Nb

6

and l-Fe

7

Mo

6

phases

are treated as one phase l. In the present optimization

work, the thermodynamic models of Fe

2

(Mo, Nb) and l

are treated as (Fe, Mo, Nb)

2

(Fe, Mo, Nb)

1

and (Fe, Mo,

Nb)

1

(Mo, Nb)

4

(Fe, Mo, Nb)

2

(Fe, Mo, Nb)

6

, respec-

tively. The models of R and r phases are Fe

32

Mo

18

(Fe,

Mo)

3

and (Fe, Mo)

10

(Fe, Mo)

20

, respectively, which are

from Reference 26.

In the Fe-Mo-Nb system, there is no magnetic contribu-

tion to the Gibbs energy of the intermetallic compounds.

Taking Fe

2

(Mo, Nb) as an example, the Gibbs energies per

mole of formula unit Fe

2

(Mo, Nb) is expressed as

G

Fe

2

Mo;NbðÞ

¼

X

i

X

j

y

0

i

y

00

j

G

Fe

2

Mo;NbðÞ

i:j

þ RT 2

X

i

y

0

i

Iny

0

i

þ

X

i

y

00

i

Iny

00

i

!

þ

X

i

X

j

X

k

y

0

i

y

0

j

y

00

k

n

L

Fe

2

Mo;NbðÞ

i;j:k

þ

X

i

X

j

X

k

y

0

i

y

00

j

y

00

k

n

L

Fe

2

Mo;NbðÞ

i:j;k

; ½7

where the dummy variables i, j,andk represent Fe, Mo,

and Nb. Parameters y

0

i

and y

0

j

are the site fractions of i

and j on the first sublattice, respectively, and y

00

j

and y

00

k

are the site fractions of j and k on the second sublattice,

respectively. Also, G

Fe

2

Mo;NbðÞ

i:j

is the Gibbs energy of the

end-members i

2

j,

n

L

Fe

2

Mo;NbðÞ

i;j:k

is the nth interaction

parameter between i and j on the first sublattice when

the second sublattice is occupied by element k.

n

L

Fe

2

Mo;NbðÞ

i:j;k

is the nth interaction parameter between j

and k on the second sublattice when the first sublattice is

occupied by i element.

C. Assessment Procedur e

Optimization was carried out using the PARROT

module in the software package Thermo-Calc,

[51]

which

is capable of handing various kinds of experimental

data. The program works by mini mizing an error sum

wherein each of the selected data values is given a

certain weight. The step-by-step modeling procedure

described by Du et al.

[52]

was utilized in the present

optimizations performed in this work. The intermet allic

compounds were optimized first based on the experi-

mental results. Then, the parameters for the solution

phases were optimized. Subsequently, the parameters

Table I. Compositions and Primary Solidification Phases of the As-Cast Fe-Mo-Nb Alloys

No.

Alloy Compositions (At Pct)

Primary Solidification Phase

Phase Compositions (At Pct)

Phase 2 Phase 3Fe Mo Nb Fe Mo Nb

#1 94.5 3.3 2.2 bcc(Fe) 93.1 3.7 3.2 Fe

2

(Mo, Nb) —

#2 90.8 6.2 3.0 bcc(Fe) 88.2 10.0 1.8 Fe

2

(Mo, Nb) —

#3 85.7 9.1 5.2 bcc(Fe) 86.9 11.2 1.9 Fe

2

(Mo, Nb) —

#4 82.9 13.2 3.9 bcc(Fe) 87.0 10.7 2.3 Fe

2

(Mo, Nb) —

#5 65.6 33.0 1.4 r 52.8 42.9 4.3 l bcc(Fe)

#6 61.7 35.2 3.1 r 51.9 43.0 5.1 l bcc(Fe)

#7 82.5 5.0 12.5 Fe

2

(Mo, Nb) 65.2 6.7 28.1 bcc(Fe) —

#8 78.0 12.5 9.5 Fe

2

(Mo, Nb) 67.9 5.2 26.9 bcc(Fe) —

#9 73.8 9.9 16.3 Fe

2

(Mo, Nb) 66.1 8.1 25.8 bcc(Fe) —

#10 69.2 16.7 13.8 Fe

2

(Mo, Nb) 65.1 14.8 20.1 l bcc(Fe)

#11 64.8 10.3 24.9 Fe

2

(Mo, Nb) 64.3 8.6 27.1 l bcc(Fe)

#12 62.1 16.8 21.1 Fe

2

(Mo, Nb) 62.1 16.5 21.4 l bcc(Fe)

#13 59.7 8.1 32.2 Fe

2

(Mo, Nb) 56.4 3.4 40.2 l —

#14 54.9 12.2 32.9 Fe

2

(Mo, Nb) 55.4 4.7 39.9 l —

#15 49.5 3.8 46.7 Fe

2

(Mo, Nb) 59.9 1.2 38.9 l bcc(Mo, Nb)

#16 74.3 23.2 2.5 l 57.2 35.1 7.7 bcc(Fe) Fe

2

(Mo, Nb)

#17 73.1 20.2 6.7 l 60.2 32.1 7.8 bcc(Fe) Fe

2

(Mo, Nb)

#18 71.1 26.5 2.4 l 58.5 37.2 4.3 bcc(Fe) Fe

2

(Mo, Nb)

#19 67.5 23.2 9.3 l 57.9 32.2 9.9 bcc(Fe) Fe

2

(Mo, Nb)

#20 65.6 28.3 6.1 l 57.3 34.5 8.2 bcc(Fe) Fe

2

(Mo, Nb)

#21 61.2 28.1 10.7 l 58.7 34.6 6.7 bcc(Fe) Fe

2

(Mo, Nb)

#22 60.9 23.6 15.5 l 57.3 32.5 10.2 bcc(Fe) Fe

2

(Mo, Nb)

#23 56.6 21.6 21.8 l 53.1 28.8 18.1 Fe

2

(Mo, Nb) —

#24 44.8 1.7 53.5 l 50.3 3.7 46.0 bcc(Mo, Nb) —

#25 56.3 41.3 2.4 bcc(Mo, Nb) 15.8 71.7 12.5 rl

#26 48.5 33.1 18.4 bcc(Mo, Nb) 6.6 62.5 30.9 l —

#27 46.2 17.3 36.5 bcc(Mo, Nb) 6.8 50.4 42.8 l —

#28 40.9 7.9 51.2 bcc(Mo, Nb) 6.1 16.0 77.9 l —

#29 40.4 28.4 31.2 bcc(Mo, Nb) 8.2 45.8 46.0 l —

#30 30.8 21.6 47.6 bcc(Mo, Nb) 6.11 27.1 66.8 l —

#31 29.1 48.5 22.4 bcc(Mo, Nb) 8.2 54.8 37.0 l —

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 50A, JULY 2019—3361

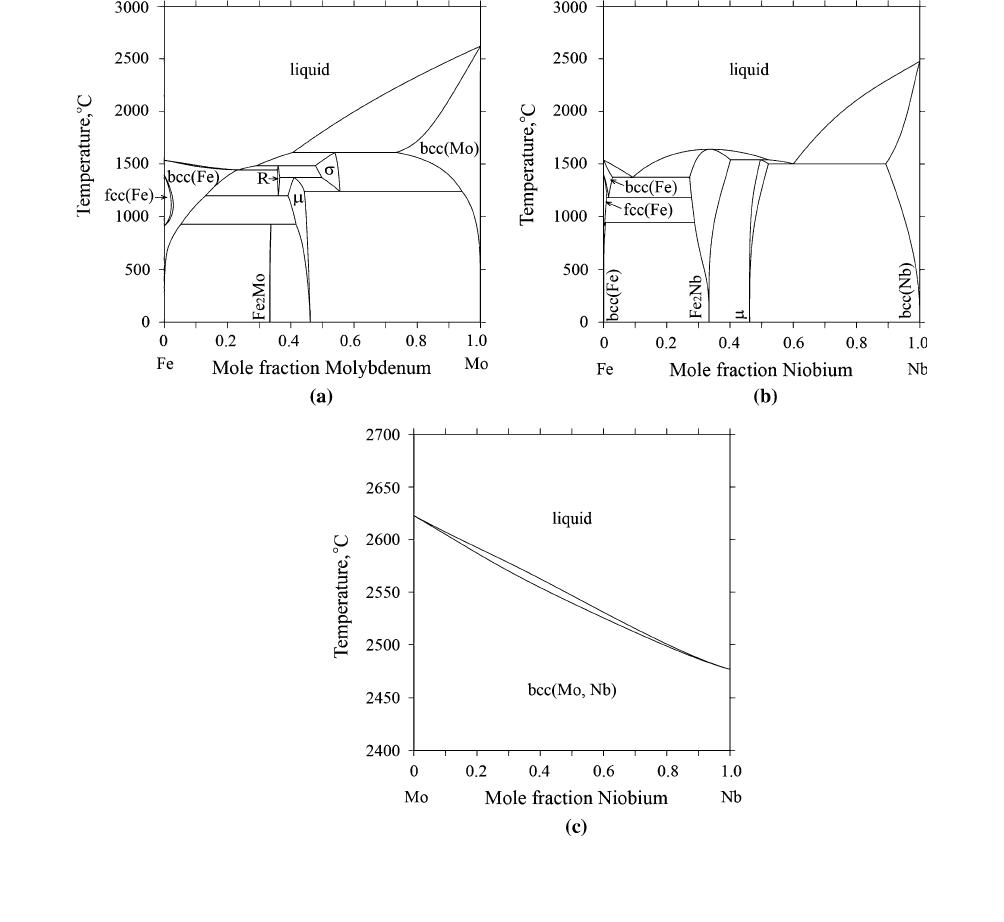

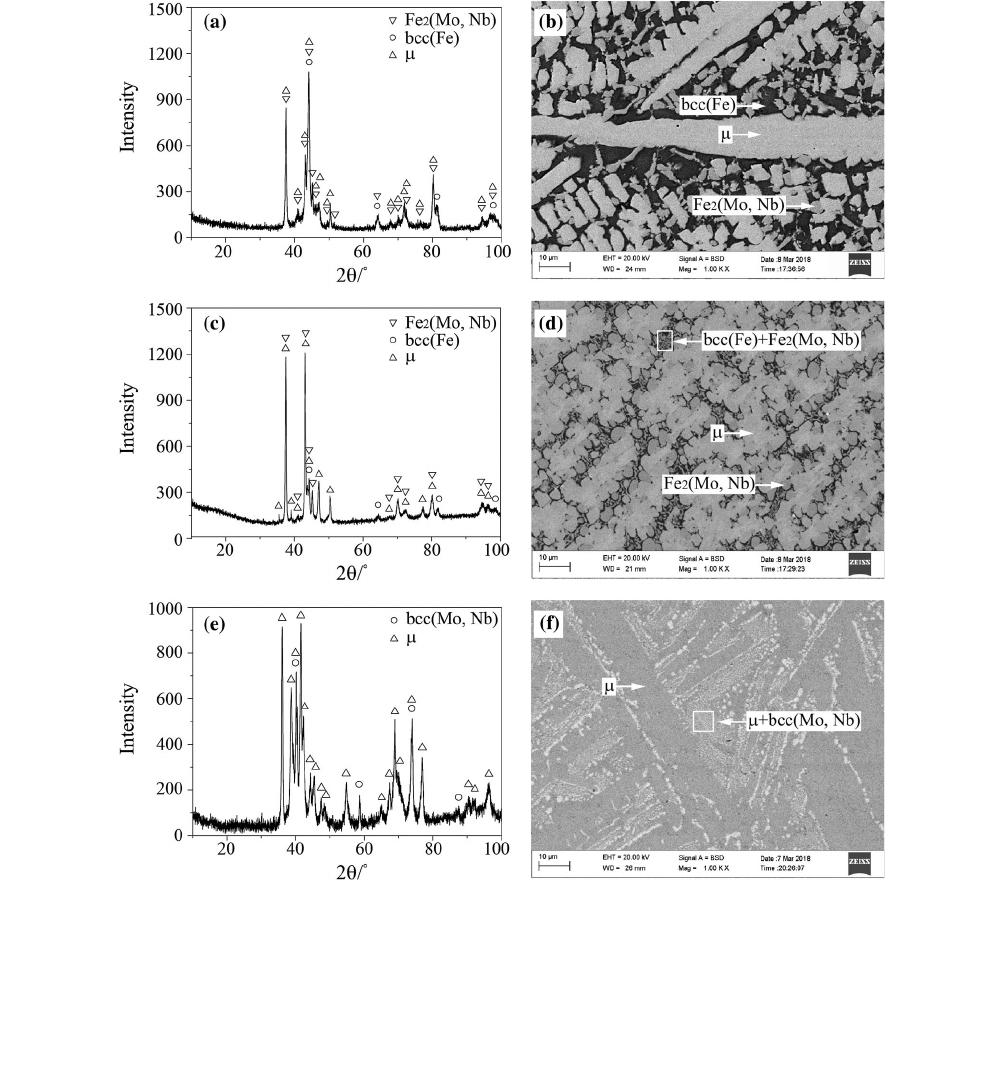

Fig. 2—XRD patterns and BSE micrographs: (a) and (b) for alloy #4; (c) and ( d) for alloy #5.

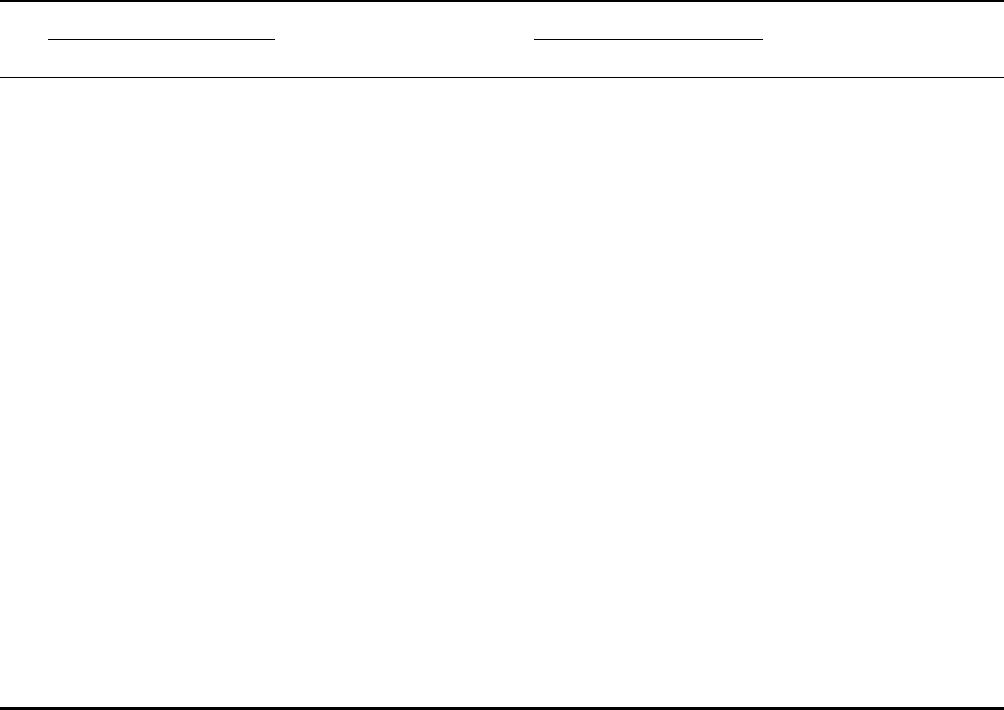

Fig. 3—XRD patterns and BSE micrographs: (a) and (b) for alloy #8; (c) and ( d) for alloy #15.

3362—VOLUME 50A, JULY 2019 METALLURGICAL AND MATERIALS TRANSACTIONS A

for the liquid phase were evaluated also based on

experimental results. Greater weights were given to the

experimental data for the isothermal sections

[47]

and the

present liquidus surface projection. Finally, all the

parameters were optimized concurrently to achieve a

set of self-consistent thermodynamic parameters.

Based on the experimental liquidus surfa ce projection

in this work and the isothermal sections from the

literature, the thermodynamic parameters for the indi-

vidual phases in the Fe-Mo-Nb system were all

optimized.

V. RESULTS AND DISCUSSION

A. Experimental Liquidus Surface Projection

To investigate the liquidus surface projection of the

Fe-Mo-Nb system, 31 alloy samples were prepared. The

compositions and primary solidification phases of the

as-cast alloys are summarized in Table I.

The primary solidification phase bcc(Fe) is observed

in alloys #1 to #4. Figures 2(a) and (b) show the XRD

pattern and backscattered electron (BSE) micrograph

obtained for alloy #4, respectively. The XRD pattern

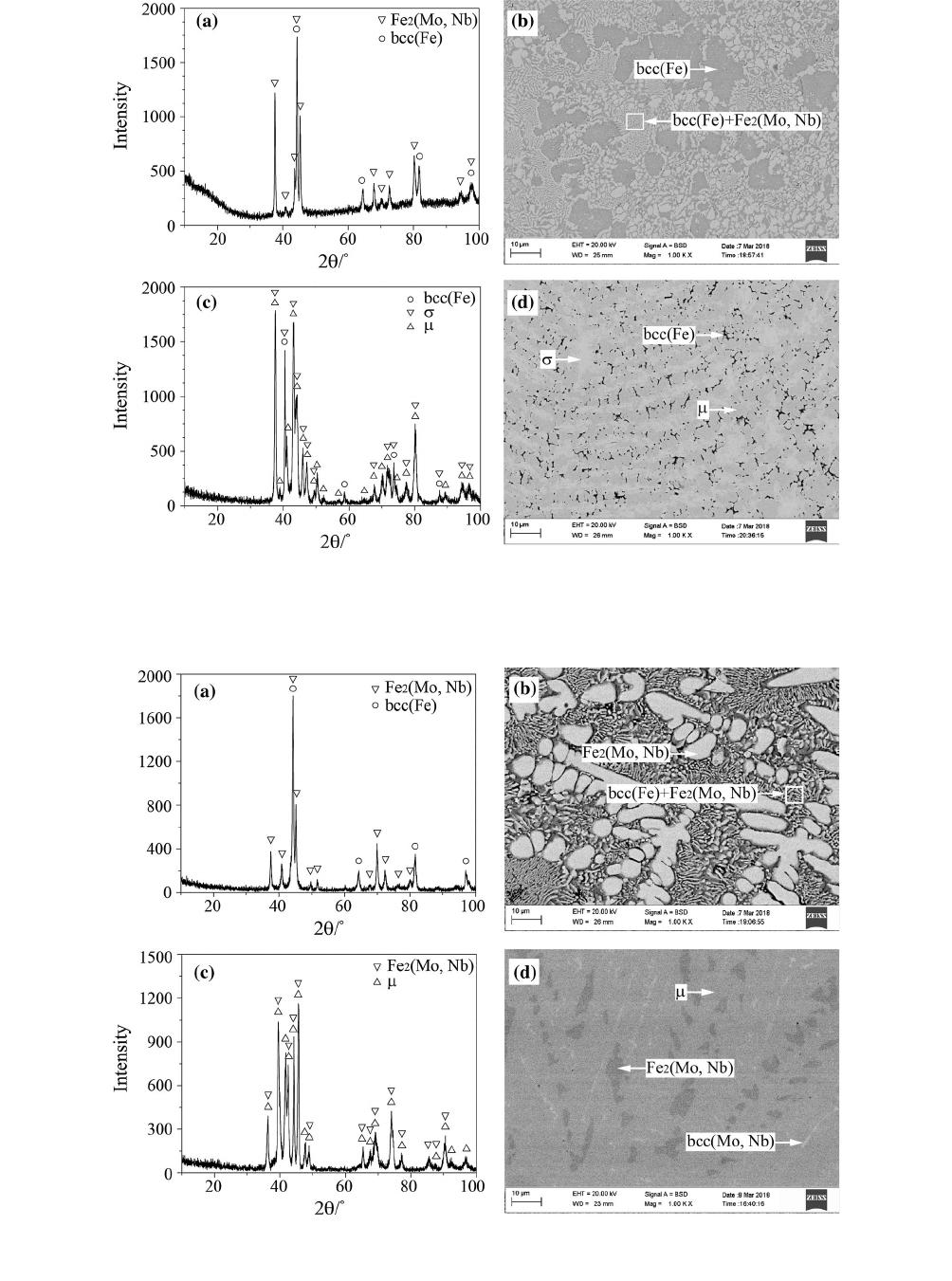

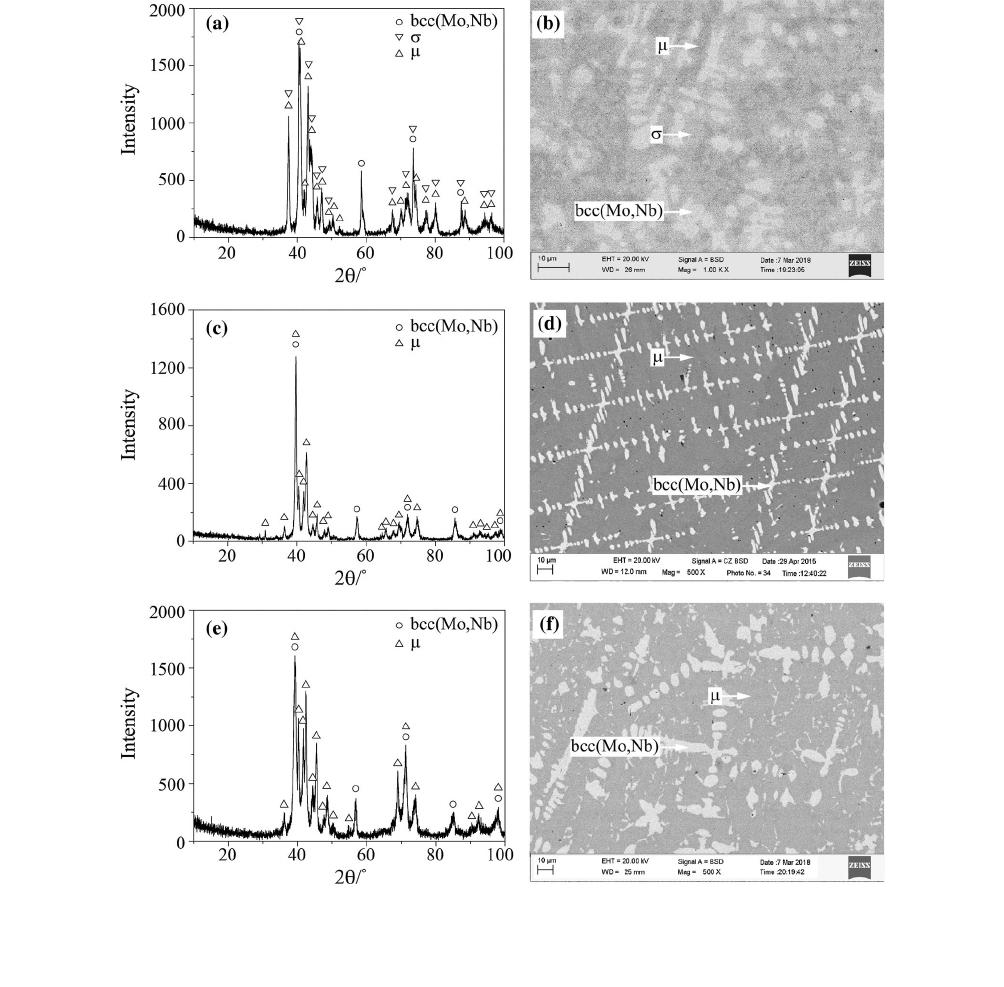

Fig. 4—XRD patterns and BSE micrographs: (a) and (b) for alloy #16; (c) and (d) for alloy #19; (e) and (f) for alloy #24.

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 50A, JULY 2019—3363

only contains diffraction peaks corresponding to bcc(Fe)

and Fe

2

(Mo, Nb), and two typical microstructures are

observed in alloy #4. The bulk gray microstr ucture is the

primary solidification phase bcc(Fe) (Fe—10.7 at. pct

Mo—2.3 at. pct Nb), and the lamellar microstructure

corresponds to a eutectic mixture of bcc(Fe) + Fe

2

(Mo,

Nb). The solidification path of alloy #4 is presumed

to be as follows: liq. fi bcc(Fe), liq. fi bcc(Fe) +

Fe

2

(Mo, Nb).

For alloys #5 and #6, the primary solidification phase

is r. The XRD pattern and BSE micrograph of alloy #5

are shown in Figures 2 (c) and (d), respectively. The

bright phase is the primary solidification phase r

(Fe—42.9 at. pct Mo—4.3 at. pct Nb). The r phase

precipitates from liquid during the solidification process

of alloy #5, and the liquid composition reaches the

monovariant line (liq. + r fi l). The l phase is form ed

around the r phase and hinders the further reaction

between the liquid and r phase, resulting in the liquid

composition crosses over the monovariant line (liq. +

r fi l) and the l phase solidifies directly from

liquid. At the end of the solidification process, the black

linear bcc(Fe) is formed by the eutectic reaction

liq. fi l + bcc(Fe).

Alloys #8 to #15 are located in the primary solidifi-

cation region of Fe

2

(Mo, Nb). According to the XRD

pattern and microstructure of alloy #8 shown in

Figures 3(a) and (b), the bright phase is the primary

solidification phase Fe

2

(Mo, Nb) (Fe—5.2 at. pct,

Mo—26.9 at. pct Nb), and the lamellar microstructure

Fig. 5—XRD patterns and BSE micrographs: (a) and (b) for alloy #25; (c) and (d) for alloy #27; (e) and (f) for alloy #28.

3364—VOLUME 50A, JULY 2019 METALLURGICAL AND MATERIALS TRANSACTIONS A

is a eutectic with microstructure of bcc(Fe) + Fe

2

(Mo,

Nb). The XRD pattern and BSE micrograph of alloy

#15 are shown in Figures 3(c) and (d), respectively.

Combining the results of XRD and EDS, the dark and

gray phase are Fe

2

(Mo, Nb) and l, respectively. The

white phase cannot be determined due to its low

content. The composition of alloy #15 is close to the

Fe-Nb side. Therefore, the Fe

2

(Mo, Nb) phase first

precipitates from liquid during the solidification process ,

and the liquid composition reaches the monovariant line

(liq. + Fe

2

(Mo, Nb) fi l). The l phase is formed

around Fe

2

(Mo, Nb) and hinders the further reaction

between liquid and Fe

2

(Mo, Nb), resulting in the liquid

composition crosses over the monovariant line (liq.+-

Fe

2

(Mo, Nb) fi l) and the l phase solidifies directly

from liquid. According to the imaging principle of back

scattered electron, the small amount of white phase is

the bcc(Mo, Nb) phase. So, the liquid composition

finally reaches the monovariant line (liq. fi l +

bcc(Mo, Nb)).

The primary solidification phase l is observed in

alloys #16 to #24. The XRD pattern and BSE micro-

graph of alloy #16 are shown in Figures 4(a) and (b),

respectively. The gray phase is the primary solidification

phase l (Fe—35.1 at. pct Mo—7.7 at. pct Nb). The

black and dark gray phases are bcc(Fe) and Fe

2

(Mo,

Nb), respectively. The XRD pattern and BSE micro-

graph of alloy #19 are shown in Figures 4(c) and (d),

respectively. The bright pha se is determined to be the

primary solidification phase l (Fe—32.2 at. pct

Mo—9.9 at. pct Nb), and the gray phase is Fe

2

(Mo,

Nb) (Fe—12.0 at. pct Mo—20.9 at. pct Nb). The lamel-

lar microstructure is the eutectic microstructure of

bcc(Fe) + Fe

2

(Mo, Nb).

Unlike alloys #16 and #19, the XRD pattern of alloy

#24 shown in Figure 4(e) confirms the existence of the

l and bcc(Mo, Nb) phases. The gray phase is the

primary solidification phase l (Fe—3.7 at. pct

Mo—46.0 at. pct Nb), and the lamellar microstructure

is the eutectic microstructure of l+bcc(Mo, Nb). The

composition of alloy #24 is close to the Fe-Nb side.

According to the Fe-Nb phase diagram, the composi-

tion of the liquid inevitably reaches the monovariant

line (liq. fi l + bcc(Mo, Nb)) with decreasing tem-

perature. Therefor e, the microstructures of the primary

solidification phase l and eutectic l+bcc(Mo, Nb) are

observed in alloy #24.

Alloys #25 to #31 are located in the primary

solidification region of bcc(Mo, Nb). The XRD pattern

and BSE micrograph of alloy #25 are shown in

Figures 5(a) and (b), respectively. The bright phase is

determined to be bcc(Mo, Nb) (Fe—71.7 at. pct

Mo—12.5 at. pct Nb). The gray phase around the

bcc(Mo, Nb) phase is r which is formed by the reactions

liq.+bcc(Mo, Nb) fi r and liq. fi r. The dark gray

phase is l which precipitates due to the peritectic

reaction liq. + r fi l. Unlike alloy #25, bright den-

dritic microstructures can be clearly observed in

Figures 5(d) and (f). Combining the experimental results

obtained using XRD and EDS, the bright primary

solidification phase corresponds to bcc(Mo, Nb).

In the present work, the primary solidification phase

R is not observed in any of the alloys.

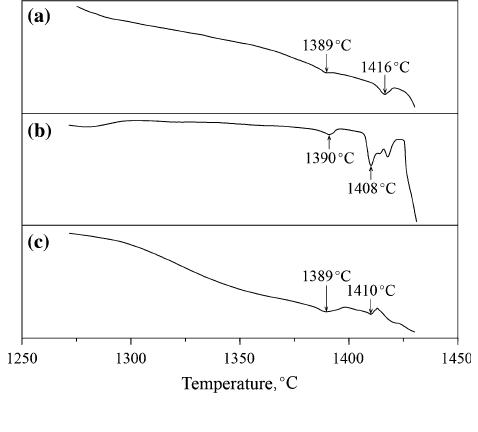

The DTA curves for a lloys #16 to #18 are shown in

Figure 6. A phase transformation peak with an onset at

1389 C can be observed in the DTA curves. According

to the experimental analysis, alloys #16 to #18 have the

same reaction in the solidification process, namely

liq. + l fi bcc(Fe) + Fe

2

(Mo, Nb). Therefore, it can

be deduced that the temperature 1389 C corresponds to

the invariant reaction liq. + l fi bcc(Fe) + Fe

2

(Mo,

Nb). Due to the temperature limitations of the DTA

instrument (SDT-Q600, TA Instruments, USA), only

the temperature of the invariant reaction liq. + l

fi bcc(Fe) + Fe

2

(Mo, Nb) is determined.

The above experimenta l results were subsequently

used to construct the liquidus surface projection of the

Fe-Mo-Nb system.

B. Thermodynamic Calculations

The thermodynamic parameters obtained for the

Fe-Mo-Nb system in the present work are listed in

Table II, and the calculated invariant reactions in the

Fe-Mo-Nb system are shown in Table III. It can be seen

that the temperature of invariant reaction U

4

is in

agreement with the DTA results in the present work.

Figure 7 shows the liquidus surface projection calcu-

lated for the Fe-Mo-Nb system using the present

thermodynamic descriptions and present experimental

data. Satisfactory agreement can be seen to have been

obtained between the calculated results and experimen-

tal data. The complete reaction scheme predicted for the

Fe-Mo-Nb system is shown in Figure 8.

Fig. 6—DTA curves of alloys: (a) #16; (b) #17; (c) #18.

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 50A, JULY 2019—3365

Table II. Thermodynamic Parameters in the Fe-Mo-Nb System

Phase Thermodynamic Parameters Refs.

Liquid model (Fe, Mo, Nb)

1

0

L

liquid

Fe;Mo

¼11712 þ 2:917T 26

0

L

liquid

Fe;Nb

¼74257 þ 99:67T 10T lnðTÞ 31

1

L

liquid

Fe;Nb

¼þ17624 10:805T 31

0

L

liquid

Mo;Nb

¼þ15253:7 43

1

L

liquid

Mo;Nb

¼þ10594 43

0

L

liquid

Fe;Mo;Nb

¼26580 :11 this work

1

L

liquid

Fe;Mo;Nb

¼145201:38 this work

2

L

liquid

Fe;Mo;Nb

¼88271 :81 this work

fcc model (Fe, Mo, Nb)

1

(Va)

1

0

L

fcc

Fe;Mo

¼þ20978 11:843T 26

0

L

fcc

Fe;Nb

¼6176 2:04T 31

T

fcc

cFe

¼201 43

b

fcc

Fe

¼2:10 43

0

L

fcc

Fe;Mo;Nb

¼þ151251:49 this work

bcc model (Fe, Mo, Nb)

1

(Va)

3

0

L

bcc

Fe;Mo

¼þ38849 9:539T 26

1

L

bcc

Fe;Mo

¼8988 26

0

T

bcc

cFe;Mo

¼þ334 26

1

T

bcc

cFe;Mo

¼þ531 26

0

L

bcc

Fe;Nb

¼10893 þ 10:288T 31

1

L

bcc

Fe;Nb

¼þ4674 5:776T 31

0

L

bcc

Mo;Nb

¼68202 þ 29:8559T 43

1

L

bcc

Fe;Nb

¼þ8201:3 43

T

bcc

cFe

¼þ1043 43

b

bcc

Fe

¼þ2:22 43

1

L

bcc

Fe;Mo;Nb

¼46852 :12 þ 30:0253T this work

2

L

bcc

Fe;Mo;Nb

¼56564 :96 þ 33:7643T this work

R model Fe

32

Mo

18

(Fe, Mo)

3

G

R

Fe:Mo:Fe

= 35GHSER

Fe

+ 18GHSER

Mo

þ 50909 177:308T 26

G

R

Fe:Mo:Mo

¼ 32GHSER

Fe

þ21GHSER

Mo

91498 83:151T 26

r model (Fe, Mo)

10

(Fe, Mo)

20

G

r

Fe:Fe

¼ 30GHSER

Fe

þ 226500 26

G

r

Mo:Fe

¼ 20GHSER

Fe

þ10GHSER

Mo

þ 487900 26

G

r

Fe:Mo

= 10GHSER

Fe

þ20GHSER

Mo

þ 31407 43:882T 26

G

r

Mo:Mo

¼ 30GHSER

Mo

þ 486900 26

0

L

r

Fe:Fe;Mo

¼48114 26

Fe

2

(Mo, Nb) model (Fe, Mo, Nb)

2

(Fe, Mo, Nb)

1

G

Fe

2

Mo;NbðÞ

Fe:Fe

= 3GHSER

Fe

þ 44130 26,31

G

Fe

2

Mo;NbðÞ

Fe:Mo

= 2GHSER

Fe

+ GHSER

Mo

20443 þ 7:289T 26

G

Fe

2

Mo;NbðÞ

Mo:Fe

¼ GHSER

Fe

+ 2GHSER

Mo

þ 50443 7:289T 26

3366—VOLUME 50A, JULY 2019 METALLURGICAL AND MATERIALS TRANSACTIONS A

Table II. continued

Phase Thermodynamic Parameters Refs.

G

Fe

2

Mo;NbðÞ

Mo:Mo

¼ 3GHSER

Mo

þ 15000 26

0

L

Fe

2

Mo;NbðÞ

Fe:Fe;Mo

¼þ70000 26

0

L

Fe

2

Mo;Nb

ðÞ

Fe;Mo:Mo

¼þ59450 26

G

Fe

2

Mo;NbðÞ

Fe:Nb

¼ 2GHSER

Fe

+ GHSER

Nb

67223 þ 13:971T 31

G

Fe

2

Mo;NbðÞ

Nb:Fe

¼ GHSER

Fe

+ 2GHSER

Nb

þ 180030 31

G

Fe

2

Mo;NbðÞ

Nb:Nb

¼ 3GHSER

Nb

þ 49620 31

0

L

Fe

2

Mo;NbðÞ

Fe:Fe;Nb

¼

0

L

Fe

2

Mo;NbðÞ

Nb:Fe;Nb

¼33816 31

G

Fe

2

Mo;NbðÞ

Mo:Nb

¼ 2GHSER

Mo

+ GHSER

Nb

þ 49750:41 this work

G

Fe

2

Mo;NbðÞ

Nb:Mo

¼ GHSER

Mo

+ 2GHSER

Nb

þ 95248:29 this work

0

L

Fe

2

Mo;NbðÞ

Fe:Mo;Nb

¼þ17917:52 16:4472T this work

1

L

Fe

2

Mo;NbðÞ

Fe:Mo;Nb

¼þ42452:16 30:4231T this work

0

L

Fe

2

Mo;NbðÞ

Fe:Fe;Mo;Nb

¼100132:03 this work

l model (Fe, Mo, Nb)

1

(Mo, Nb)

4

(Fe, Mo, Nb)

2

(Fe, Mo, Nb)

6

G

l

Fe:Mo:Fe:Fe

¼ 9GHSER

Fe

+ 4GHSER

Mo

þ 74090 76:677T 26

G

l

Fe:Mo:Fe:Mo

¼ 3GHSER

Fe

+ 10GHSER

Mo

þ 445950 26

G

l

Fe:Mo:Mo:Fe

¼ 7GHSER

Fe

+ 6GHSER

Mo

68875 þ 8:955T 26

G

l

Fe:Mo:Mo:Mo

¼ GHSER

Fe

+ 12GHSER

Mo

þ 340960 26

G

l

Mo:Mo:Fe:Fe

¼ 8GHSER

Fe

+ 5GHSER

Mo

þ 100890 26

G

l

Mo:Mo:Fe:Mo

¼ 2GHSER

Fe

+ 11GHSER

Mo

þ 484770 26

G

l

Mo:Mo:Mo:Fe

¼ 6GHSER

Fe

+ 7GHSER

Mo

þ 23550 26

G

l

Mo:Mo:Mo:Mo

¼ 13GHSER

Mo

þ 394940 26

0

L

l

Fe:Mo:Fe;Mo:Fe

¼137510 þ 105:096T 26

G

l

Fe:Nb:Fe:Fe

¼ 9GHSER

Fe

+ 4GHSER

Nb

100230 31

G

l

Nb:Nb:Fe:Fe

¼ 8GHSER

Fe

+ 5GHSER

Nb

27430 31

G

l

Fe:Nb:Nb:Fe

¼ 7GHSER

Fe

+ 6GHSER

Nb

266116 þ 56T 31

G

l

Nb:Nb:Nb:Fe

¼ 6GHSER

Fe

+ 7GHSER

Nb

131400 31

G

l

Fe:Nb:Fe:Nb

¼ 3GHSER

Fe

+ 10GHSER

Nb

þ 426530 31

G

l

Nb:Nb:Fe:Nb

¼ 2GHSER

Fe

+ 11GHSER

Nb

þ 499200 31

G

l

Fe:Nb:Nb:Nb

¼ GHSER

Fe

+ 12GHSER

Nb

þ 176020 31

G

l

Nb:Nb:Nb:Nb

¼ 13GHSER

Nb

þ 227500 31

G

l

Fe:Mo:Nb:Fe

¼ 7GHSER

Fe

+ 4GHSER

Mo

+ 2GHSER

Nb

146415:80þ10:0590T

this work

G

l

Fe:Nb:Mo:Fe

¼ 7GHSER

Fe

+ 2GHSER

Mo

+ 4GHSER

Nb

85904:30þ13:9406T this work

G

l

Mo:Nb:Nb:Fe

¼ 6GHSER

Fe

+ GHSER

Mo

+ 6GHSER

Nb

this work

G

l

Nb:Mo:Nb:Fe

¼ 6GHSER

Fe

+ 4GHSER

Mo

+ 3GHSER

Nb

this work

G

l

Nb:Nb:Mo:Fe

¼ 6GHSER

Fe

+ 2GHSER

Mo

+ 5GHSER

Nb

this work

G

l

Fe:Mo:Fe:Nb

¼ 3GHSER

Fe

+ 4GHSER

Mo

+ 6GHSER

Nb

this work

G

l

Fe:Nb:Fe:Mo

¼ 3GHSER

Fe

+ 6GHSER

Mo

+ 4GHSER

Nb

this work

G

l

Fe:Nb:Mo:Mo

¼ GHSER

Fe

+ 8GHSER

Mo

+ 4GHSER

Nb

this work

G

l

Fe:Mo:Nb:Nb

¼ GHSER

Fe

+ 4GHSER

Mo

+ 8GHSER

Nb

this work

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 50A, JULY 2019—3367