Selective Deposition of C-axis Oriented Pb

5

Ge

3

O

11

on the Patterned High k

Gate Oxide by MOCVD Processes

Tingkai Li,

Sheng Teng Hsu, Bruce Ulrich, Dave Evans

Sharp Laboratory of America, Inc. 5700 NW Pacific Rim Blvd. Camas, WA 98607

ABSTRACT

For the high density FeRAM applications, the integration process-induces damages such as

etching damage that degrades the properties of FRAM devices and the high surface roughness of

ferroelectric thin film that results in the difficulty for alignment are critical issues. In order to

solve these problems, selective deposition process is developed to simplify the integration

processes and improve the properties of FeRAM memory devices. Based on the differential

deposition rates of ferroelectric materials on high-k oxide and silicon dioxide, we can selectively

deposit a c-axis oriented PGO thin film on the patterned high-k oxide such as ZrO

x

(x=0-2),

HfO

x

(x=0-2), TiO

2

, and their mixtures other than on SiO

2

. By patterning the high-k dielectric,

the PGO deposition is limited to just the preferred pattern high-k area. SEM, EDX and x-ray

measurements further confirm that the c-axis oriented PGO thin films are selectively deposited

on the high-k gate oxide other than on the field SiO

2

including alignment mark area, which will

eliminate the roughness problem for the alignments. Also the etching damage is eliminated

since there is no need to etch the PGO film, which improved the properties of FeRAM devices.

INTRODUCTION

The remanent-polarization states of ferroelectric capacitors have long been of interest for

nonvolatile storage of digital data [1-5]. The recent approach to ferroelectric memories has been

to integrate the ferroelectric memory capacitor into a random access memory circuit on an

integrated circuit to convert semiconductor RAMs to a nonvolatile form. Most of the studies on

Ferroelectric Random Access Memories (FeRAM) have been concentrated on the memory

structure with one transistor and one capacitor (1T1C), and one transistor (1T) memory devices

with MFMIS (Metal/Ferroelectrics/Metal/Insulator/Silicon) and MFIS structures have also been

fabricated recently [6-10]. However, for smaller devices and higher density application of

FeRAM devices, the ferroelectric thin film are related to the integration process induced

damages, which degrades the working function of FeRAM devices [11]. Therefore, we

improved the integration processes including damascene structure, selective deposition and

chemical mechanical planarization (CMP). For 1T memory devices, C-axis oriented Pb

5

Ge

3

O

11

thin films showed the very good ferroelectric and electrical properties for the 1T-memory device

applications. Extremely high c-axis oriented PGO thin films can be deposited on high k gate

oxides, and the working 1T-memory devices with PGO MFIS memory cell have also been

fabricated.

In this paper, we proposed the selective deposition technologies for c-axis oriented PGO thin

films on high k gate oxides including ZrO

X

(x=0-2), HfO

X

(x=0-2), TiO

2

, Al

2

O

3

, La

2

O

3

and their

mixtures to simplify the integration processes and improve the properties of PGO MFIS

transistor ferroelectric memory devices. There is no need to etch ferroelectric material; as a

Mat. Res. Soc. Symp. Proc. Vol. 784 © 2004 Materials Research Society C9.9.1/E9.9.1

result the etching induced damage is avoided. Due to the selective deposition of PGO on

patterned high k gate oxide other than on field oxide, the alignment problem is also solved.

2. THE EXPERIMENTAL METHODS AND RESULTS

P type Si wafers were used as the substrates of PGO MFIS one-transistor devices. The

integration processes including STI, polysilicon or nitride gate replacement for damascene

structures, high k gate oxide deposition, pattern and etching, MOCVD selective deposition,

CMP etc. have been used for the one-transistor memory device, as shown in Fig. 1a - 1f. The

detail integration processes are as follows.

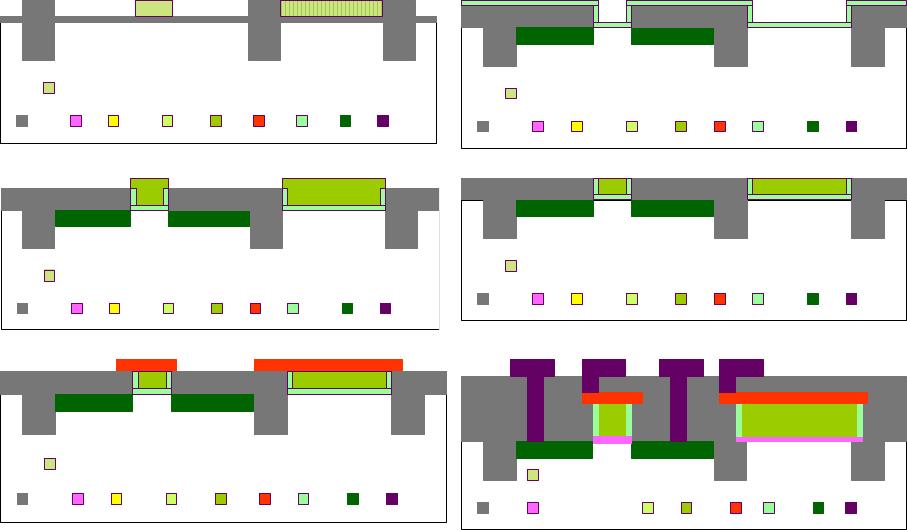

Fig.1a shows the processes including threshold adjustment ion implantation, grow gate oxide,

CVD nitride, STI photoresist, CVD oxide, CMP oxide stopped at nitride, photoresist, and

etch Nitride.

Fig.1b shows the processes including source and drain ion implantation, CVD oxide. CMP

oxide

stopped at nitride wet etches nitride and gate oxide, and deposition of high k gate oxide.

Fig.1c shows the processes including pattern and etch high k oxides (such as HfO

2

) stopped at

field oxide (SiO

2

), and selective deposition of ferroelectric thin film (such as PGO) on

high k gate oxides (such as HfO

2

).

Fig.1d shows the process of CMP ferroelectric thin film (such as PGO) stopped at oxide.

Fig.1e shows deposition of top electrodes and patterned the electrodes.

Fig.1f shows the final device structure including etching contact holes and metallization.

Oxide BE Resist Poly FE TE TiO2 N+ Metal

Nitride

A

Oxide BE Resist Poly FE TE HfO2 N+ Metal

Nitride

B

Oxide BE Resist Poly FE TE HfO2 N+ Metal

Nitride

C

Oxide BE Resist Poly FE TE HfO2 N+ Metal

Nitride

D

Oxide BE Resist Poly FE TE HfO

2

N+ Metal

Nitride

E

Oxide high k gate oxide FE Poly TE HfO2 N+ Metal

Nitride

F

Fig. 1 The integration processes for the MFIS 1T memory devices

C9.9.2

/E9.9.2

The etching and pattern high k gate oxides is a critical process for the PGO MFIS 1T

transistor memory device applications, as shown in Figure 1c. We developed the following

processes to pattern HfO

2

: In the first step, we deposited Hf metal on SiO

2

, then patterned Hf

metal, and finally annealed Hf metal at forming gas or oxygen atmosphere to transfer the Hf

metal into HfO

2

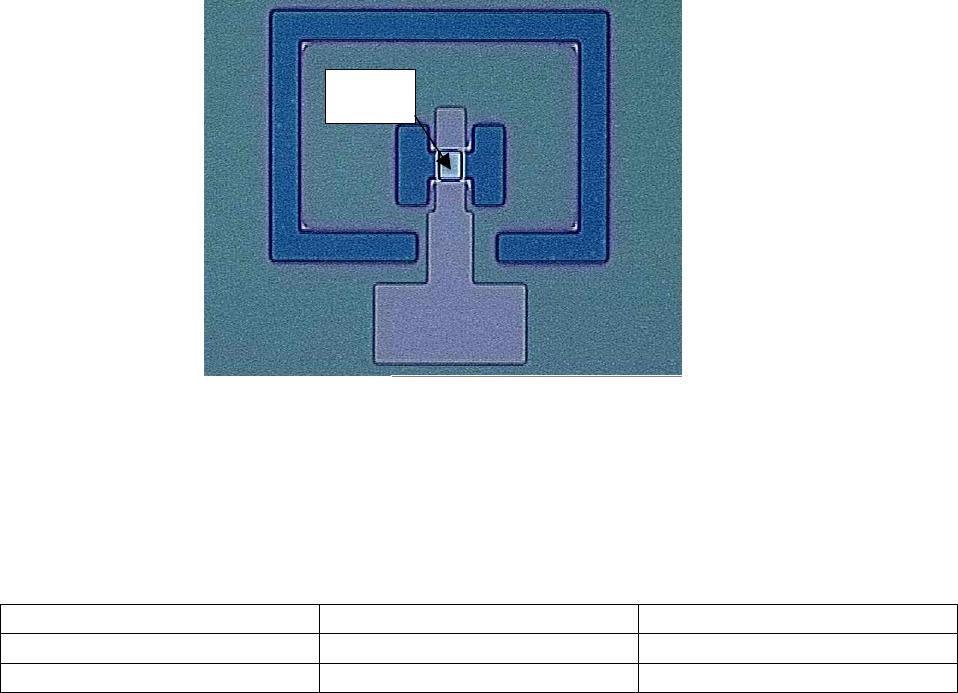

. Figure 2 shows the patterned HfO

2

using dry etching processes.

Fig. 2 The patterned Hf thin films using dry etching processes

According to experimental results, MOCVD PGO thin films deposited on high-k gate oxide

and SiO2 have different deposition rates and different microstructures, as shown in table 1.

Because the huge difference between the deposition rates of PGO grown on HfO

2

to PGO grown

Table 1. The deposition rates of PGO grown on HfO

2

and SiO

2

Deposition rates (nm/hour) Crystallization

PGO on HfO

2

200 - 300 Oriented crystallized film

PGO on SiO

2

1 - 5 Amorphous film

on SiO

2

, PGO thin films can be selectively deposited on HfO

2

other than on field oxide of SiO

2

.

The following is the detail of selective MOCVD processes. [Pb(thd)

2

] and [Ge(ETO)

4

] with a

molar ratio of 5 – 5.5:3

were dissolved in a mixed solvent of butyl ether or tetrahydrofuran,

isopropanol and tetraglyme in the molar ratio of 8:2:1. The precursor solutions had a

concentration of 0.1 M/L of PGO. The solution was injected into a vaporizer at temperature in

the range of 150 – 240ºC by a pump at a rate of 0.02 – 0.2 ml/min to form precursor gases. The

feed line was kept at 150 - 245ºC.

Substrate: patterned HfO

2

and field SiO

2

Deposition temperatures: 500 - 520ºC, Deposition pressure: 1 - 10 torr

Oxygen partial pressures: 30 – 50%.

Vaporizer temperature: 180 - 200ºC

Vaporizer pressure: 30 - 50 torr.

Solution delivery rates: 0.02 - 0.2 ml/min

Deposition time: 1 - 3 hours depending on film thickness

Annealing temperatures: 500 - 560ºC, Annealing time: 5 – 30 minutes at O

2

HfO2

C9.9.3/E9.9.3

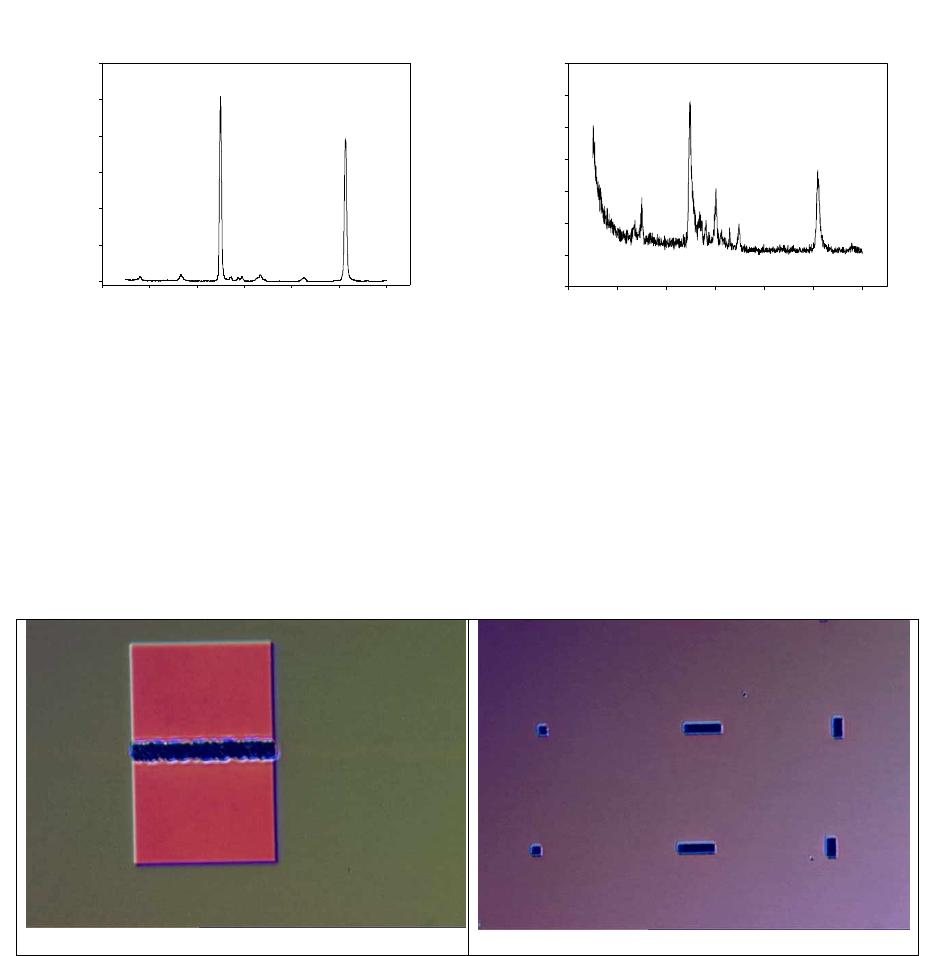

Fig. 3 shows the x-ray pattern of PGO thin film deposited on HfO

2

gate oxide of test wafer. As

is shown in the figure, the extremely high c-axis oriented PGO thin film is obtained. Fig. 4

shows the x-ray pattern of PGO thin film selective deposited on patterned HfO

2

device wafers.

The x-ray pattern confirmed that the selective deposited thin films on patterned HfO

2

device

wafer is c-axis oriented PGO thin film.

2 Theta

0 102030405060

Counts/S

0

2000

4000

6000

8000

10000

12000

001

002

003

006

004

005

Fig. 3 X-ray pattern of PGO thin films

deposited on HfO

2

test wafer

2 Theta

0 102030405060

Counts/S

-50

0

50

100

150

200

250

300

001

002

003

006

004

005

Fig. 4 X-ray pattern of PGO thin films

deposited on patterned HfO

2

device wafer

Fig. 5A and 5B show the microphotographs of selective deposition of PGO thin films on HfO

2

.

These figures confirmed PGO thin films have been selective deposited on HfO

2

gate oxide other

than on SiO

2

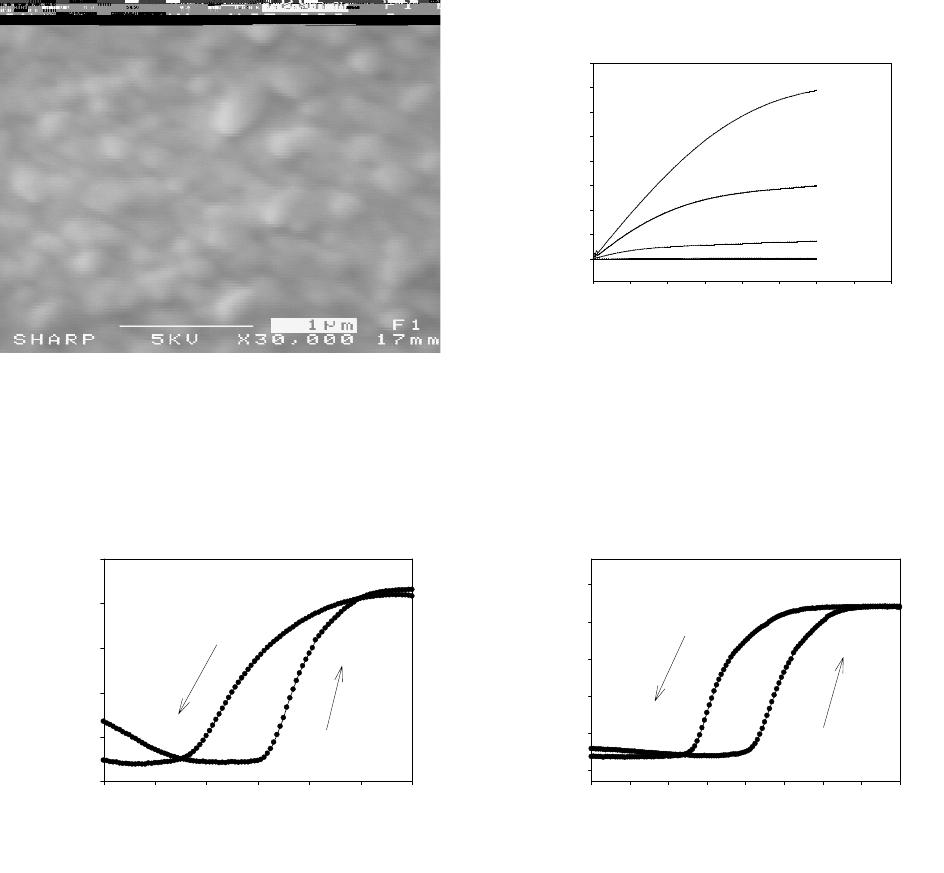

. Fig. 6 shows the microstructure of PGO thin film deposited on HfO

2

substrate.

The grain size of PGO thin films deposited on HfO2 is about 0.3 µm.

A

B

Fig. 5 The microphotographs for PGO selective deposition on HfO

2

gate oxide

Using MOCVD PGO selective deposition technologies, damascene structure and CMP

processes, the 1T MFIS memory device have been fabricated. Fig. 7 shows the drain current (I

D

)

versus drain voltage (V

D

) with various gate voltages of 10 x10 µm 1T memory device. The

C9.9.4

/E9.9.4

drain current (I

D

) increased with increasing drain voltage (V

D

). The drain current (I

D

) also

increased with increasing gate voltage (V

G

). The behavior showed a typical working function of

a transistor device. Fig. 8a and 8b shows the I

D

– V

G

curves of 1T MFIS memory devices with

device size of 5 x10 µm and 10 x10 µm respectively. The memory window is about 2V, the

drain current at “off” state with V

D

of 0.1 V is about 2 x 10

-12

A, and the drain current at “on”

state with V

D

of 0.1 V is about 4 x 10

-8

A. The ratio of “on/off” states is about 4 orders, which

is enough for memory device applications.

Fig. 6 The microstructure of PGO thin film

deposited on HfO2 substrate

Fig. 7 The drain current (I

D

) versus drain

voltage (V

D

) with various gate voltages

A. Device size: 5 x10 µm

B. . Device size: 10 x10 µm

Fig. 8 The I

D

– V

G

curves of 1T MFIS memory devices with device size

of 5 x10 µm and 10 x10 µm

Drain voltage (V

D

)

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

Drain Current I

D

(A)

0

2.0x10

-5

4.0x10

-5

6.0x10

-5

8.0x10

-5

10

-4

1.2x10

-4

1.4x10

-4

1.6x10

-4

V

g

: 3 V

V

g

: 4 V

V

g

: 5.0 V

V

g

: 1, 2 V

Gate voltage (V

G

)

-3-2-1012345

Drain Current I

D

(A)

10

-12

10

-11

10

-10

10

-9

10

-8

10

-7

From -5V to +5V

From +5V to -5V

Gate voltage (V

G

)

-1012345

Drain Current I

D

(A)

10

-12

10

-11

10

-10

10

-9

10

-8

10

-7

From -5V to +5V

From +5V to -5V

C9.9.5

/E9.9.5

MFIS (Metal/Ferroelectrics/Insulator/Silicon) transistor ferroelectric memory devices have been

fabricated. For the small device and high density 1T FeRAM device applications, the selective

deposition processes have been developed to simplify the integration processes and improve the

properties of MFIS transistor ferroelectric memory devices. Based on the different deposition

rates of ferroelectric materials on high-k oxide and silicon dioxide, we can selectively deposit a

c-axis oriented PGO thin film on the patterned high-k oxide such as ZrO

x

(x=0-2), HfO

x

(x=0-

2), TiO

2

, and their mixtures other than on SiO

2

. By patterning the high-k dielectric, the PGO

deposition is limited to just the preferred pattern high-k area. SEM, EDX and x-ray

measurements further confirmed that the c-axis oriented PGO thin films were selectively

deposited on the high-k gate oxide other than on the field SiO

2

. The etching damage is

eliminated since there is no need to etch the PGO film. The properties of 1T MFIS memory

devices are also improved.

REFERENCES

1. Ramtron Corporation (Colorado Springs, CO) started introducing its 4Kbit, 8Kbit, and

16Kbit FRAMs in 1988.

2. S.B. Desu and Tingkai. Li, Mat. Sci. and Eng. B 34, L4-L8 (1995).

3. C.A. Paz de Araujo, J. D. Cuchiaro, L.D. McMillan, M.C. Scott & J.F. Scott, Nature, 374,

13, 627-629 (1995).

4. Tingkai Li, Y.F. Zhu, S.B. Desu, C.H. Peng, and N. Masaya, Appl. Phys. Letters 68 (5), 616

(1997).

5. Tingkai Li, F.Y. Zhang and S.T. Hsu, Appl. Phys. Lett. 74 (2) 296 (1999).

6. S. Imada, S. Shouriki, E. Tokumitsu, and H. Ishiwara, Jpn. J. Appl. Phys. 37, 6497 (1998).

7. Tingkai Li, S. T. Hsu, B. Ulrich, H. Ying, L. Stecker, D. Evans, Y. Ono, J. S. Maa, J. J. Lee

Appl. Phys. Lett. 79 (11) 1661 (2001).

8. Tingkai Li, S. T. Hsu, B. Ulrich, L. Stecker, D. Evans, J. J. Lee, IEEE Electron Device

Letters, vol. 23, No. 6, 339 (2002).

9. E. Tokumitsu, G. Fujii and H. Ishiwara, Jpn. J. Appl. Phys. vol. 39, 2125 (2000).

10. Tingkai Li, S. T. Hsu, B. Ulrich, D. Evans, IEEE Transactions on Electron Devices, vol. 50,

No.11, 2280 (2003)

11. Tingkai Li, S. T. Hsu, B. Ulrich, L. Stecker, D. Evans, Jpn. J. Appl. Phys. Vol.41, 6890

(2002).

C9.9.6/E9.9.6

3. SUMMARY