Mater. Res. Soc. Symp. Proc. Vol. 1577 © 2013 Materials Research Society

DOI: 1 557/op 0130.1 l.2 .

High Mobility IGZO/ITO Double-layered Transparent Composite Electrode: A Thermal

Stability Study

Aritra Dhar

1

and T. L. Alford

1,2

1

Department of Chemistry and Biochemistry,

2

School for Engineering of Matter, Transport, and Energy,

Arizona State University, AZ 85287, U.S.A.

ABSTRACT

The fabrication of a thin film optoelectronic device involves the exposure of the transparent

conductive oxide (TCO) to a high process temperature. Indium gallium zinc oxide (InGaZnO

4

or

IGZO) is a well known TCO with high optical transparency, moderate conductivity and high

mobility. However, its electrical properties deteriorate after subsequent high temperature

processes in air atmosphere. On the other hand indium tin oxide (ITO) has higher conductivity

than IGZO and better thermal stability. Therefore, IGZO/ITO bilayers have been deposited on

glass by radio frequency magnetron sputtering at room temperature and subsequently annealed at

high temperatures in order to study their thermal stability. In the present work, a-IGZO layers

with a thickness ranging from 10 nm to 100 nm were deposited over a 50 nm thick ITO layer.

Results are compared with those from a single IGZO layered thin film without the ITO bottom

layer. The structural, optical and electrical properties of the multilayers are studied with the use

of scanning electron microscopy, UV–Vis spectroscopy and Hall measurement. An IGZO

optimal thickness of 50 nm is found to improve the bilayer thermal stability at temperatures upto

400 °C keeping good opto-electrical properties. The sheet resistance for the optimized

IGZO/ITO composite films is about 22 Ohm/sq, and the transmittance in the visible range is

about 90%. The composite shows an excellent mobility above 40 cm

2

/V-s and thus can be

potentially applied as channel layer in thin film transistors (TFTs)

INTRODUCTION

Transparent conducting oxides (TCO) have been widely used for various optoelectronic

applications such as solar cells, [1] flat panel displays [2], gas sensors [3] and organic light

emitting diodes [4]. TCO thin films are critical for solar cell devices since they constitute a

essential part in the future generations of photovoltaic (PV) devices [5]. The most important

criteria for a TCO is to have high visible transparency and good electric conductivity. Also, low

cost abundance, non toxicity, and simple fabrication methods at an industrial scale are other

important characteristics to be considered for the selection of a TCO electrode for photovoltaic

applications [6-10]. However, apart from these conventional characteristics, processing of PV

devices requires high thermal and chemical stability, surface electrochemical properties and

room temperature fabrication. For this reason, the research for new materials or various

composites had been extensively studied to improve the performance and efficiency of the TCO

662

thin films. ITO is the most common and widely used TCO which has good properties in terms of

high transparency and conductivity[8-13]. The advantage of ITO is that it can be easily

fabricated at room temperature by magnetron sputtering [5] on both glass and plastic substrates.

However, it looses its good electrical conductivity on thermal annealing at 350 °C in air

atmosphere [6]. On the other hand amorphous Indium gallium zinc oxide (a-IGZO) is another

potential TCO material which can also be easily deposited at ambient temperature by RF

magnetron sputtering. However the as-deposited IGZO samples have poorer electrical

conductivity, but show a high improvement in conductivity when annealed at high (over 300 °C)

temperatures. On the basis of these rationalities, the main objective of the present research work

is focused on the development of a double-layered transparent composite IGZO/ITO electrode.

The bilayer thin films are deposited without direct substrate heating, and expected to exhibit

good electrical properties even when annealed at higher temperature. The thermal stability of the

thin film had been studied and the effect of annealing in various environments had been

discussed in details.

EXPERIMENTAL DETAILS

IGZO/ITO double-layered transparent composite electrodes were deposited on 2 mm thick

soda-lime glass substrates at room temperature by two sequential RF magnetron sputtering

processes of ITO and InGaZnO

4

targets. The In and Ga content is about 25 at. % and 35 at. %

respectively, in the mixed oxide. The base pressure of the sputter system prior to each deposition

was approximately 1x10

−7

Torr. The deposition was performed at a pressure of 10 mTorr for ITO

and 20 mTorr for IGZO in pure Ar gas (99.999%). The depositional parameters for sputtering of

both the individual metal oxides had been optimized prior to the bilayer deposition. The ITO and

IGZO layers were deposited using an rf power of 100 W and 150 W, respectively. The target-to-

substrate distance was maintained at 6 cm for all the depositions. The thickness of the ITO and

IGZO layers were measured using optical ellipsometry. The bottom ITO layer was kept constant

at 50 nm while the top IGZO layer was varied between 10 nm to 100 nm. Post deposition, the

IGZO/ITO bilayers were annealed at 100 °C, 200 °C, 300 °C and 400 °C in a quartz tube furnace

in air atmosphere for 3 hours in order to study their thermal stability. Optical transmittance of the

multilayers were measured using an Ocean Optics double channel spectrometer (model DS200)

in the wavelength range of 300–800 nm with an air reference for transmittance. Tungsten

halogen and deuterium lamps were used as sources for visible and UV light, respectively. Hall

measurements were done using a HMS3000 instrument. Electrical resistivity, Hall mobility, and

carrier concentration of the films were measured by means of the Van der Pauw method. A

magnetic field of 0.98 T was applied perpendicular to the sample surface.

RESULTS

IGZO and ITO thin films exhibit a considerably different behavior in their electrical

properties when they are exposed at high temperatures (Fig. 1). The as-deposited has lower

electrical resistivity at room temperature than ITO and it became better on thermal annealing at

above 300

o

C. However the electrical resistivity in IGZO is seen to increase with annealing

temperature and showed significant rise after 300

o

C. However, in both the materials shallow

donor levels present near the conduction band results in forming Drude-like absorption in far

infrared wavelengths [7] leaving the material transparent in the visible region (400–800 nm). For

IGZO films, this donor levels come from oxygen intrinsic defects and impurity doping.

Now, it is seen that ITO is stable under high temperature processes. On the other hand, IGZO

layers deposited at room temperature can show different behavior in their conductivity

depending on the post-deposition annealing temperature and also on the annealing environment.

The variations are attributed mainly due to change in their carrier concentration because of the

creation or annihilation of donor oxygen vacancies and changes in the effective doping of In and

Ga onto Zn lattice sites [7]. After heating at 300 °C in air the conductivity increases mainly due

to carrier concentration increase. But on annealing above this temperature in air atmosphere,

there is a sharp decline in the conductivity due to the isolation of interstitial metal atoms in grain

boundaries and the annihilation of oxygen vacancies. However, the as-deposited IGZO/ITO

bilayer is seen to have lower sheet resistance and exhibit little increase in electrical resistance on

thermal annealing above 300

o

C in air atmosphere.

Fig.1 Sheet resistance vs. annealing temperature in air for 50 nm thick individual ITO, IGZO

thin films and IGZO/ITO composites.

Fig. 2 shows the effect of increasing IGZO top layer on the electrical properties of IGZO/ITO

bilayer where both resistivity and sheet resistance shows a sharp decrease on addition of a 10

nm of IGZO layer. The effective resistivity of the bilayer continues to decrease with increase in

IGZO thickness. The effective resistivity of the bilyaer is seen to drop down to almost 1 order of

magnitude from the initial resitivity of as-deposited ITO sample. A 50 nm thick as-deposited

IGZO thin films shows a resistivity and sheet resistance of 9.7 x 10

-3

ohm.cm and 1.07 x 10

3

ohm/sq respectively at room temperature.

Fig. 2 Effective resistivity and sheet resistance of IGZO/ITO multilayer films

Figure 3 shows the change in carrier concentration and hall mobility as a function of IGZO

thickness for IGZO/ITO bilayer. The plot indicates that both carrier concentration and hall

mobility increase sharply with the addition of IGZO layer and continues to increase with the

addition of thicker IGZO layer. The carrier concentration of the bilayer has increased from 1.3 x

10

19

to 10.2 x 10

20

cm

-3

upon increase of IGZO thickness from 10 to 100 nm. Also the hall

mobility of the bilayer increased to a maximum of 44 cm

2

/V-s from 23 cm

2

/V-s in case of only

ITO thin films.

Fig. 3 Hall mobility and Carrier concentrations of IGZO/ITO multilayer films.

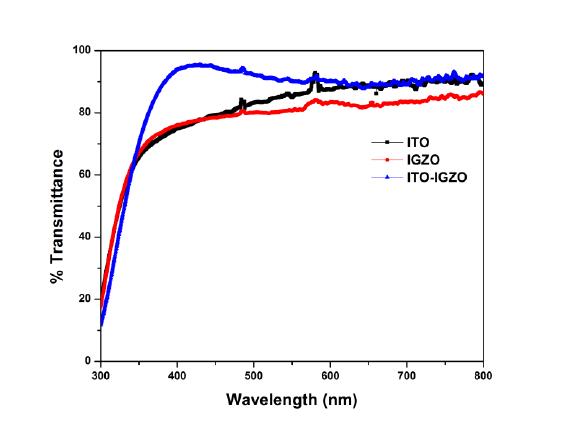

Figures 4 show optical transmittance spectra for individual oxides and IGZO/ITO multilayer on

glass substrate. The maximum optical transmittance of the pure single-layer ITO and IGZO thin

films are about 87% and 81% respectively, in the visible region. The transmittance was seen to

increase in the bilayer than the individual oxides.

Fig. 4 Optical transmittance spectra for individual oxides and IGZO/ITO multilayer on glass

substrate

For the IGZO/ITO bilayer electrodes in Fig. 4, increasing the IGZO thickness to 50 nm shows

high transmittance. However, a further increase thereafter results in poorer average optical

transmittance. Preliminary results suggest that the optimized bilayer electrode doesn’t exhibit

any significant decrease in optical transmittance when annealed upto 400

o

C for 24 hours which

suggest the high thermal stability of the composite.

CONCLUSION

Novel IGZO/ITO bilayers transparent composite electrodes were successfully deposited on

glass substrates by RF magnetron sputtering at room temperature. An ITO layer is found to be

able to provide thermal stability in terms of electrical conductivity at temperatures over 300 °C

in air atmosphere. However the IGZO/ITO bilayer showed better electrical conductivity both as-

deposited and post-annealed than the individual thin films. The strongly stable structure of ITO

prevents the oxygen diffusion during the annealing, therefore it avoids the oxygen vacancy

annihilation in IGZO, keeping its good electrical properties. The IGZO optimal thickness was

found to be 50 nm, thinner layers do not provide as good protection, however thicker layers

deteriorate the electrode series resistance.

.

ACKNOWLEDGMENTS

This work was partially supported by the National Science Foundation (C. Ying, Grant No.

DMR-0902277) to whom the authors are greatly indebted.

REFERENCES

[1] E. Harlev, T. Gulakhmedova, I. Rubinovich, and G. Aizenshtein, Adv. Mater. 8, 994,

(1996).

[2] C. Guillén, J. Herrero , Thin Solid Films 520 (2011) 1

[3] G. Gustafsson, Y. Cao, G.M. Treacy, F. Klavetter, N. Colaneri, and A. J. Heeger,

Nature 357, 477, (1992).

[4] C. G. Granqvist, Appl. Phys. A 52, 83, (1991).

[5] H. C. Lee, and O. O. Park, Vacuum 75, 275, (2004).

[6] A. E. Hichou, A. Kachouane, J. L. Bubendorff, M. Addou, J. Ebothe, M. Troyon, and

A. Bougrine, Thin Solid Films 458, 263, (2004).

[7] J. Montero, C. Guillén, J. Herrero, Thin Solid Films 519, 7564,(2011).

[8] D. C. Look, Semicond. Sci. Technol. 20, S55, (2005).

[9] A. Dhar and T. L. Alford, J. Appl. Phys. 112, 103113 (2012).

[10] A. Indluru and T. L. Alford, J. Appl. Phys. 103, 013708, (2008).

[11] S. W. Chen, and C. H. Koo, Mater. Lett. 61, 4097, (2007).

[12] K. H. Choi, J. Y. Kim, Y. S. Lee, and H. J. Kim, Thin Solid Films 341, 152, (1999).

[13] M. K. Sinha, S. K. Mukherjee, B. Pathak, R. K. Paul, P. K. Barhai, Thin Solid Films

515, 1753, (2006).

[14] M. Gadre and T. L. Alford, Appl. Phys. Lett. 99, 051901 (2011)