Journal of Micro-Bio Robotics

https://doi.org/10.1007/s12213-020-00137-0

RESEARCH PAPER

Teleoperation control scheme for magnetically actuated

microrobots with haptic guidance

Ehab Al Khatib

1

· Xiao Zhang

1

· Min Jun Kim

1

· Yildirim Hurmuzlu

1

Received: 1 April 2020 / Revised: 22 July 2020 / Accepted: 28 July 2020

© Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract

An external magnetic field can be used in remotely controlling magnetic microrobots, making them promising candidates

for diverse biomedical applications, including cell manipulation and therapy. This paper presents a teleoperation scheme

to control magnetically actuated microrobots. The system was developed to allow human operators to control the motion

for magnetically actuated microrobots and feel their interactions with the environment. The potential applications of the

presented system will be in targeted drug delivery, micro-assembly, and biopsy procedures. A haptic interface constituted

the core of the teleoperation system. It was used to provide the operator with force feedback to control the microrobots. In

particular, virtual interaction forces were computed and transmitted to the human operators to guide them in performing path

following tasks. The operating field of the microrobots was haptically rendered to avoid contacts with obstacles. Finally,

a basic set of experimental trials were conducted, demonstrating that the average path tracking error was reduced by 67%

when haptic feedback was used.

Keywords Microrobot · Teleoperation · Haptic · Motion control · Magnetically actuated robot

1 Introduction

Microscale robots, especially untethered ones, have been

intensively investigated due to the many possible applica-

tions: micro-manipulation, micro-fabrication, drug delivery,

tissue manipulation, in situ sensing, cell therapy and in

vivo diagnostics [1]. For example, in biomedical applica-

tions, microrobots can act as co-robots that directly work

on human patients, alongside healthcare providers, perform-

ing critical medical procedures. Such ideas have deep roots

in popular culture and may even be considered the final

frontier of medical microrobotics [2]. While most of the

This work was funded by the National Science Foundation (CMMI

1623324)

Electronic supplementary material The online version of

this article (https://doi.org/10.1007/s12213-020-00137-0) contains

supplementary material, which is available to authorized users.

Yildirim Hurmuzlu

1

Department of Mechanical Engineering, Southern Methodist

University, Dallas, TX 75275, USA

microrobots presented here are based on autonomous tech-

niques [1, 3–5], there is increasing importance in human-

in-the-loop strategies. For safety, public acceptance, and

responsibility [6], it is helpful to equip human operators

with efficient and intuitive ways for manipulating the micro-

robots. One such way is haptic feedback, making it an

important approach in these human-in-the-loop teleopera-

tion schemes [7 , 8].

Thus far, several haptic feedback devices have been

developed to control and manipulate microrobots. Bhatti

et al. [9] designed an intuitive haptic interface for Atomic

Force Microscopy (AFM), which estimates haptic force at

the end of the tip by using geometric deformation prin-

ciples. Another technique for haptic feedback is visual

sensing. Pacchierotti et al. [10] presents a particle-filter

based algorithm to track the position of a robot wirelessly

while a 6-DOF haptic interface enables the operator to

remotely move a microrobot to its target position. Boukhni

fer and Ferreira [11] used a 1-DOF haptic feedback to

employ a passivity-based approach with bilateral and robust

fault tolerant control. Mohand Ousaid et al. [12] investi-

gated a modular microteleportation system that includes

custom components designed to take into account passiv-

ity and transparency constraints. Mehdi Ammi and Antoine

Ferreira [13] use 3-D vision with haptic rendering for

J Micro-Bio Robot

manipulation and penetration of cells. Asgari et al. [14]

offer a method to represent the mechanical properties of

biological cells by considering a hybrid model of micro-

nano multi particles and continuum approaches. Abou Seif

et al. [15] present a telemanipulation system for param-

agnetic microparticles. A disturbance observer was used

to estimate the forces at both the haptic interface and the

microrobot. Guix et al. [ 16] designed microrobots with

an onboard vision-based 2D micro-force sensor. But, the

limitation of such a robot is the size where the footprint

is 719 μm × 1144 μm, which is relatively large in the

micro-robotics scales. While effective, these p reliminary

systems have no mechanism to estimate the ambient forces

acting on micro-robots when they encounter an unknown

fluid or obstacle. For this purpose, we propose the devel-

opment of a master-slave system for force feedback and

manipulation of micro/nano objects where force estimation

is not needed.

The magnetic tweezer system has six magnetic poles for

releasing magnetic field fluxes to generate magnetic field

gradients. By applying current to certain electromagnetic

coils on the poles, different magnetic gradient fields can

interact with magnetized microrobots to produce propulsion

magnetic forces [17–22]. The magnetic tweezer system

requires microrobots to be magnetic only without imposing

any restrictions on the structure or the rigidity [23].

Therefore, it can only affect magnetized objects, offering

advantages for in-vivo environments, as the biological

substances are mostly non-magnetized [23, 24]. In our

previous work, this magnetic tweezer system has achieved

closed-loop control for real time 3D manipulation and

swarm motion [5, 25], with inputs given through a

user customized control interface. However, to develop

the system further for human-in-the-loop application,

alternative methods to apply control inputs are necessary.

In this paper, we integrate a haptic device together with

the magnetic tweezer system to achieve path planning of

microrobots with the implementation of an artificial poten-

tial field in conjunction with a virtual grid map. We focus

on the teleoperation control of the magnetically actuated

microrobots and haptic rendering of the environment.

There are very few studies that incorporate haptic feed-

back with magnetic actuation in controlling microrobots.

The related work can be found in [10]. The difference is,

their robots utilize micro-jets powered by catalysis, and

magnetic field is used only for steering. Fabrication of the

robots in [10] requires elaborate chemical processes to build

robots that generate micro jets. In addition, haptic-feedback

provided to the user in the form of on/off vibrations when

a contact with a wall is detected using imaging data. Hap-

tic feedback is also used to feel the inertia of the robots to

facilitate steering. This approach relies on visual data for

operational as well as position feedback purposes.

The main contribution of the present paper is in the

way the force is computed as well as how it is rendered

to the user (what is called “interaction technique” in the

VR and Haptics fields.) The robots presented here are

simple ferro-magnetic beads, because there is no need for

on-board actuation. We use two artificial potential fields

one to render the environment and another for trajectory

tracking. The haptic feedback for external interaction is

not an on/off process. It is rather a proportional force

that provides the user with more realistic sensing of the

environment. For example, in our case, the user knows that

an obstacle is being approached and can avoid collision

altogether. Furthermore, we can render attractive potential

fields to facilitate more effective trajectory tracking. In our

method visual data is needed for position feedback only. If

an alternative method to acquire the position of the robots

can be used (such as ultrasound or magnetic sensing fields),

our approach does not need visual data altogether.

The rest of this paper is organized as follows. System

setup and the introduction of master and slave subsystems

are shown in Section 2. Section 3 illustrates the control

scheme for teleoperation. The mechanisms of the potential

field and haptic controller are discussed in Section 4.

Section 5 elaborates the experiment analysis, and the

conclusion is in Section 6.

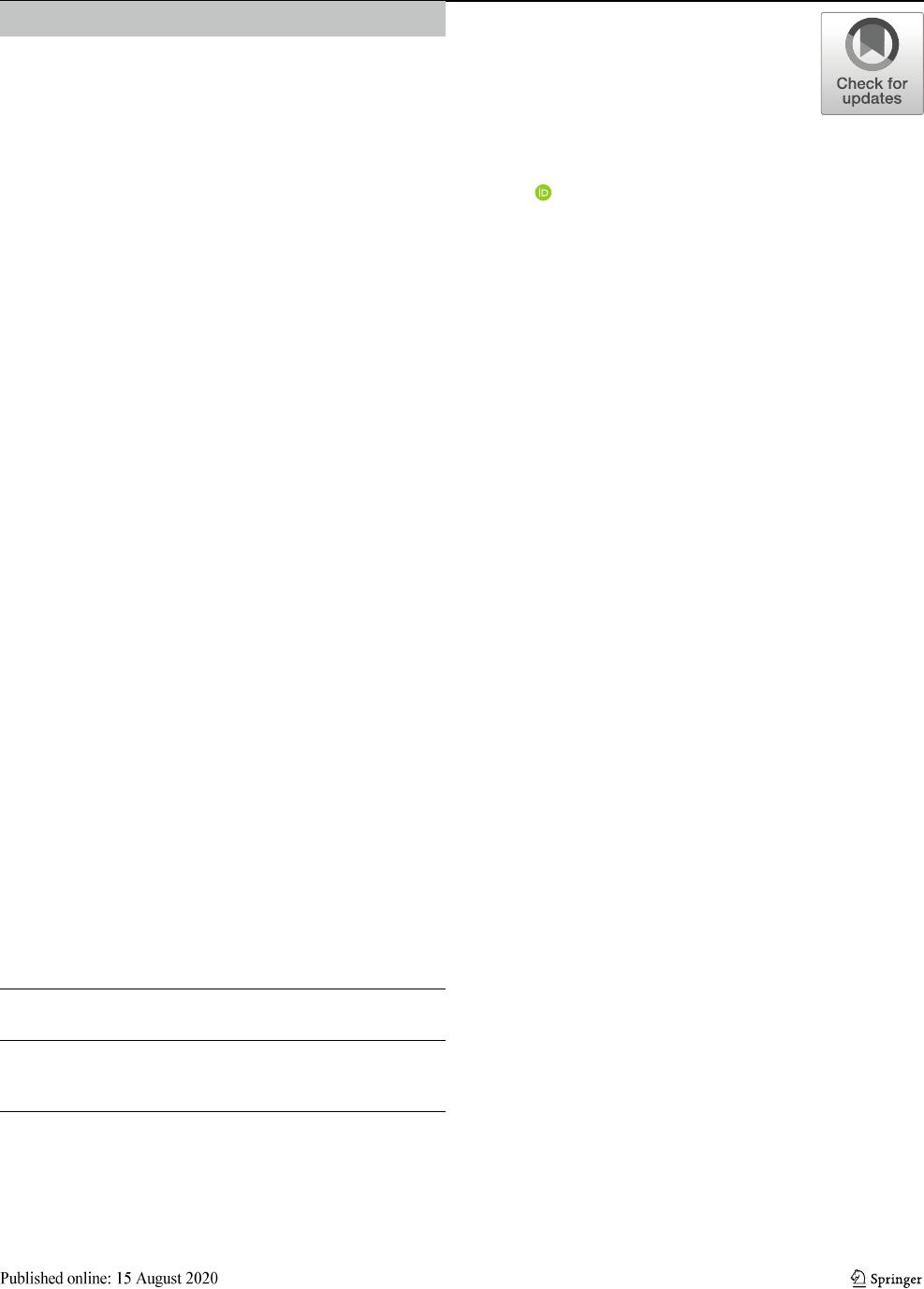

2 Overview of the system

The experimental setup used for microrobot teleoperation is

shown in Fig. 1. The master device is a Novint Falcon haptic

device, while the slave system is the magnetic tweezer with

a magnetically actuated microrobot. The control algorithm

and communications software infrastructure make use of

Robotic Operating System (ROS) libraries and Matlab.

This selection simplifies developing, debugging and testing

stages.

The teleoperation system considered in this paper is

showninFig.1. The human operator commands the micro-

robot slave by moving the haptic device. This motion is

translated into forces that will be applied by the magnetic

actuation system. Lastly, when the microrobot approaches

an obstacle, the virtual interaction forces are transmitted to

the Falcon haptic interface, rendering the terrain as force

feedback.

2.1 The master device

The Novint Falcon is a haptic device, which has a 3-

DOF grip connected via three parallel arms. It can also be

used as a 3-DOF position input and force feedback device

[26]. It was chosen because of its low cost, simplicity, and

suitability for the current project.

J Micro-Bio Robot

Fig. 1 Overview of the

teleoperation system: The

virtual interaction forces are

computed and transmitted to the

human operator to guide him in

performing path-following

tasks. The position of the haptic

device is used to compute the

motion commands sent to the

magnetic tweezer

The Falcon library translates cartesian pose state vector

to the ROS-based network using our customized software.

2.2 The slave station

The slave station consists of magnetically actuated micro-

robots, the magnetic tweezer [17], and a camera with a

microscope. The station will be connected to a computer for

visual feedback processing and implementation of motion

control. The microrobots are 10 μm coated ferromagnetic

particles.

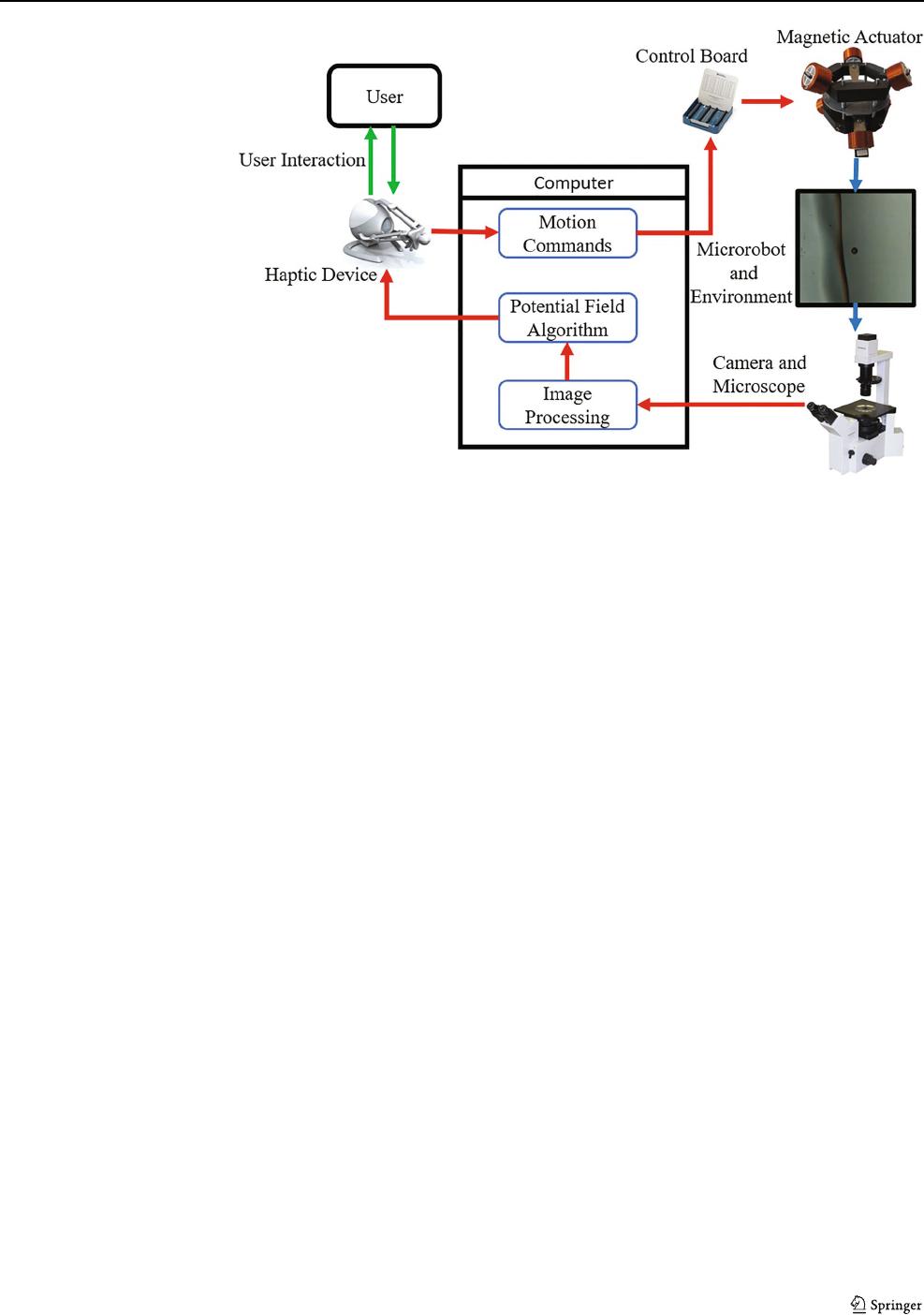

Magnetic particles are acted upon by forces that are

generated by an external magnetic field (B). In this study,

the magnetic force acting on a microrobot is given b y

f

magnetic

= (c.∇)B (1)

where, c is the magnetic moment of the magnetic particle

and ∇B is the magnetic field gradient. In Stokes flow, the

drag force on a microrobot undergoing translational motion

can be written as,

f

drag

=−ζ

P

x (2)

ζ = 6 πγr (3)

where,

P

x is the translational velocity of the microrobot in

x,y,z-directions with radius of r, γ is viscosity of the fluid,

and ζ is the spherical microrobot drag coefficient, which is

commonly known as Stokes’ law [27]. Figure 2 shows the

free-body diagram of the microrobot. Thus, the equation of

motion of the microrobot can be derived as follows:

m

¨

x − f

drag

= f

magnetic

(4)

where m is the mass of the microrobot.

3 Teleoperation control schemes

In this section, the three control strategies of teleoperation

are adopted from [28]aregivenas:

3.1 Position-position

The simplest and most intuitive teleoperation scheme is the

position-position control [29]). This control scheme maps

the master displacement to d esired slave displacement.

In order to overcome dimensional differences between

master/slave workspaces, a convenient scaling criteria or

a convenient clutching mechanism may be used. In our

application, however, this scheme requires closed-loop

position control on the slave side.

3.2 Position-velocity

When the slave workspace is significantly greater than

the one of the master, a scaling problem may arise.

One way of solving this issue is to map the master

device displacement to the slave desired velocity. This

mapping scheme provides more reliable performance and

is appropriate for teleoperation of microrobots with infinite

workspaces. Hence, similar to the position-position scheme,

it requires a velocity closed-loop control on the slave side.

3.3 Position-force

Similar to position-velocity scheme, the position-force

control scheme provides better performance when the slave

workspace is greater than the master’s. In this case, the

J Micro-Bio Robot

Fig. 2 a Microrobot in a static

fluid b The free-body diagram

of microrobot, which illustrates

the magnetic force and drag

force acting on the microrobot

forces applied to the slave are defined by the displacement

of the master. Therefore, the master displacement is

translated into magnetic force using

f

magnetic

= Kx

h

(5)

where, x

h

is the haptic device displacement and K is the

scaling matrix. To guarantee stability of the overall system,

a passivity-based approach has been adopted in the design

of the control scheme.

Assuming that the system is passive with respect to

the haptic tool, and if the interconnection between the

haptic tool and the microrobot cannot generate energy (i.e.

passive). Then, it can be concluded that the system is passive

and, therefore, stable. Thus, if the passivity is preserved by

Eq. 5, the overall system is guaranteed to be stable. From

Eqs. 4 and 5,ifx

h

is zero, then f

magnetic

is zero and the f

drag

will dissipate the energy. Then, it can be concluded that the

system is passive and stable.

4 Haptic guidance

The potential field algorithm we selected can be precom-

puted for the entire environment. Therefore, it will be

rapidly executed during runtime. It is a universal algorithm

that can be used for both path following guidance and ren-

dering obstacles imposed by the environment. Finally, it is

simple and can be used in a wide range of environments and

can handle higher degree of freedom tasks.

A virtual force can be generated by the environment and

the desired path to give the user a haptic feeling about the

workspace. This can be expressed as obstacle avoidance and

path following problem. Thus, we used artificial potential

fields to generate haptic forces to avoid obstacles and

follow a predefined path. The obstacles generate a repulsive

potential field, and the desired path generates an attractive

potential field. The two fields can be used separately to

perform each task and can be combined to perform the two

tasks in parallel.

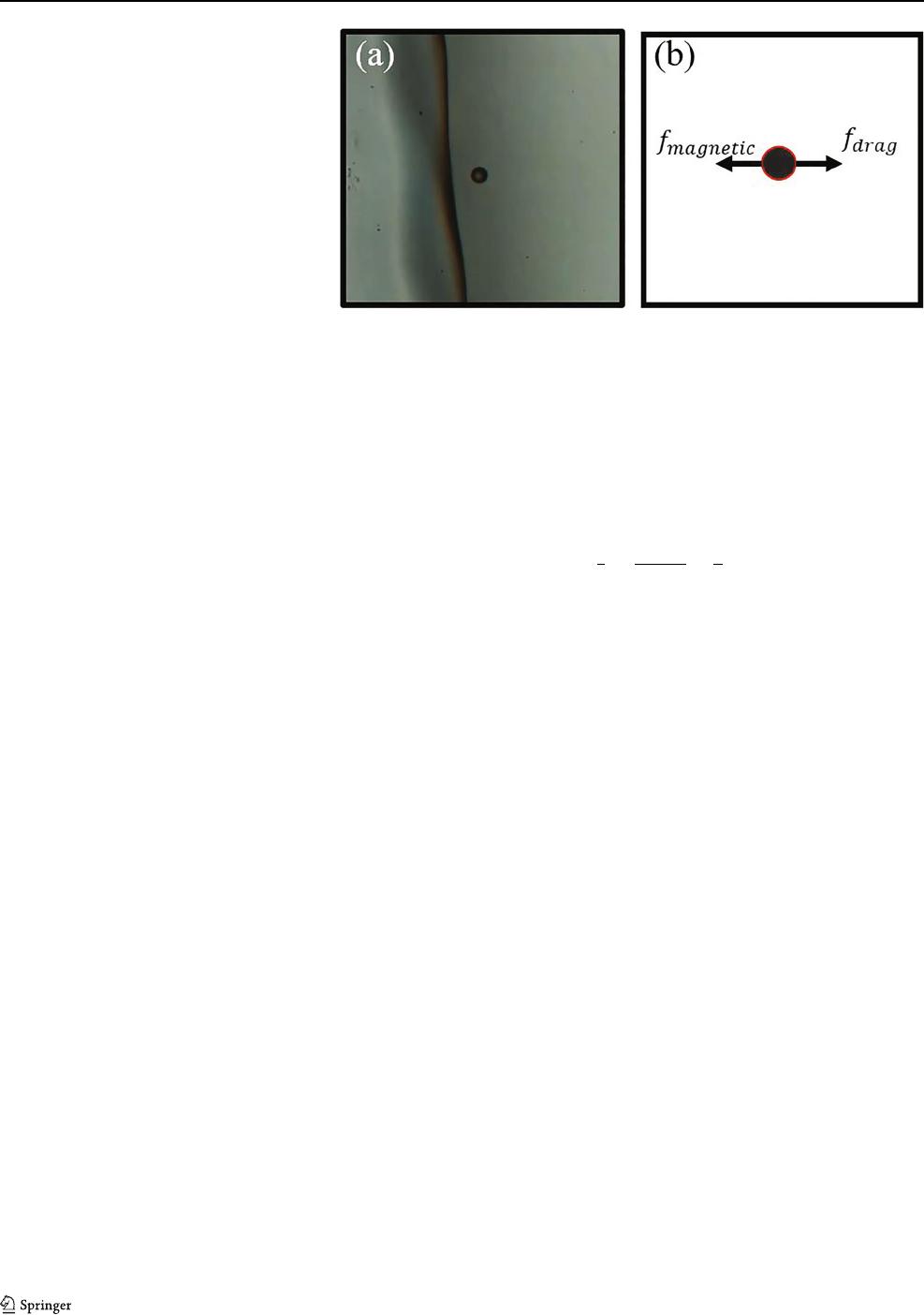

4.1 Haptic rendering of the environment

Here, we used an artificial potential field to avoid obstacles.

First, a grid is generated and superimposed on the

environment. Then, each grid cell occupied by an obstacle

contributes a repulsive potential field as shown in Fig. 3.We

define C as a set of all occupied cells. The potential field U

i

is generated by a single cell c

i

∈ C as follows:

U

i

(x, x

c

i

) =

⎧

⎨

⎩

1

2

η

1

x−x

c

i

−

1

ρ

,

x − x

c

i

≤ ρ

0 , otherwise

(6)

where, x is the robot position, x

c

i

is the occupied cell

position, η is a positive scaling factor, and ρ is the range of

influence.

The resultant repulsive force is obtained from the

negative gradient of the repulsive potential. The repulsive

force exerted by each occupied cell is,

F

i

(x, x

c

i

) =−∇U

i

(x, x

c

i

) (7)

Using superposition, the total potential field U of all

occupied cells is:

U =

c

i

∈C

U

i

(x, x

c

i

) (8)

and the total repulsive force exerted by the environment on

the robot is given by:

F =−

c

i

∈C

∇U

i

(x, x

c

i

) (9)

Subsequently, the force F will be transmitted to the

Falcon haptic device in order to give the operator the

sensation that the microrobot is approaching an obstacle.

Figure 3 shows the obstacles and the boundaries, as well

as the generated artificial potential field. As can be seen,

each obstacle is surrounded by a potential field with a

specific area of influence. Therefore, once the microrobot

enters the field, the operator starts feeling the generated

J Micro-Bio Robot

Fig. 3 Representation of the

environment. a Occupancy Grid

Mapping of the environment. b

Thegridmapwitharepulsive

potential field due to obstacles. c

3D presentation of the repulsive

field due to the obstacles

forces. As shown in Fig. 3c, the potential field gradient

around the obstacle position causes the forces to increase

proportionally as the microrobot gets closer to the obstacle.

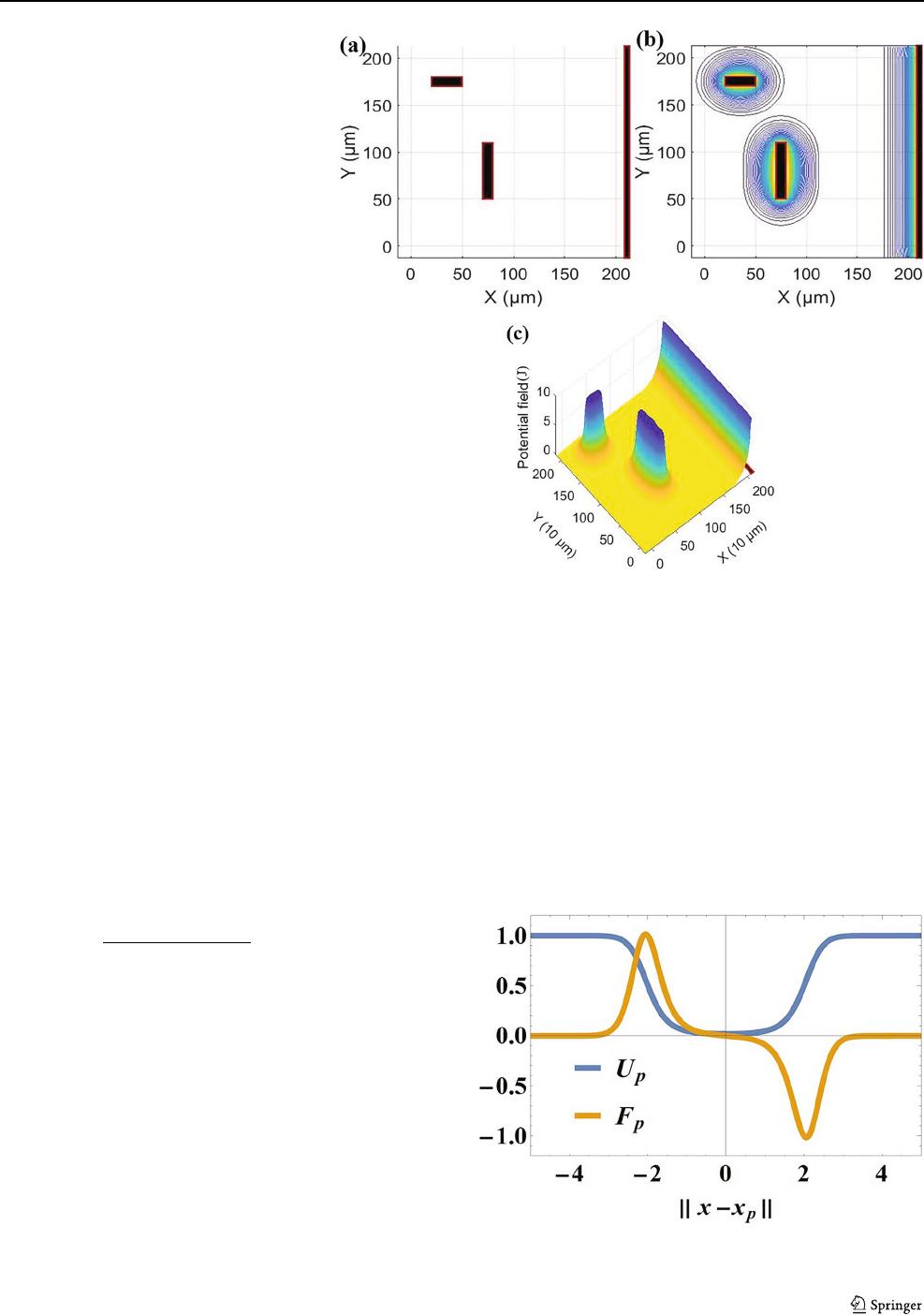

4.2 Motion tracking

The haptic guidance problem can be addressed as a path

following problem. The goal is to minimize the distance

between a single microrobot and a predefined path. An

algorithm based on the artificial potential field is used

to generate a constrained motion in the proximity of the

desired path. The proposed attractive potential field U

p

is

expressed as:

U

p

(x, x

p

) =

1

1 + e

−(

x−x

p

2

−τ

2

)

(10)

where, x and x

p

are the microrobot and path point positions

respectively, and τ is the radius of attraction. The attractive

force can be easily derived as the negative gradient of the

field as given in

F

p

(x, x

p

) =−∇U

p

(x, x

p

) (11)

The potential field is constant, as the distance between

the robot and path is small, and therefore, its gradient van-

ishes. In addition, as the distance starts increasing the poten-

tial field increases, and its gradient changes and reaches its

maximum and minimum at τ and −τ respectively. As we

get further away from the desired path, the field becomes

constant again as shown in Fig. 4.

The artificial potential field around the desired path

serves as a guide for the operator. As the microrobot moves

along the path, the operator does not feel any force, but

when the operator drives the microrobot away from the

path, the operator feels forces indicating that the microrobot

is drifting. In this mode, the haptic feedback will guide

and influence but not constrain the operator to move the

microrobot along the desired path. The tracking accuracy

relies on visual feedback and the operator. This mode

combines visual and haptic feedback.

Fig. 4 The attractive field due to the path, when τ = 2

J Micro-Bio Robot

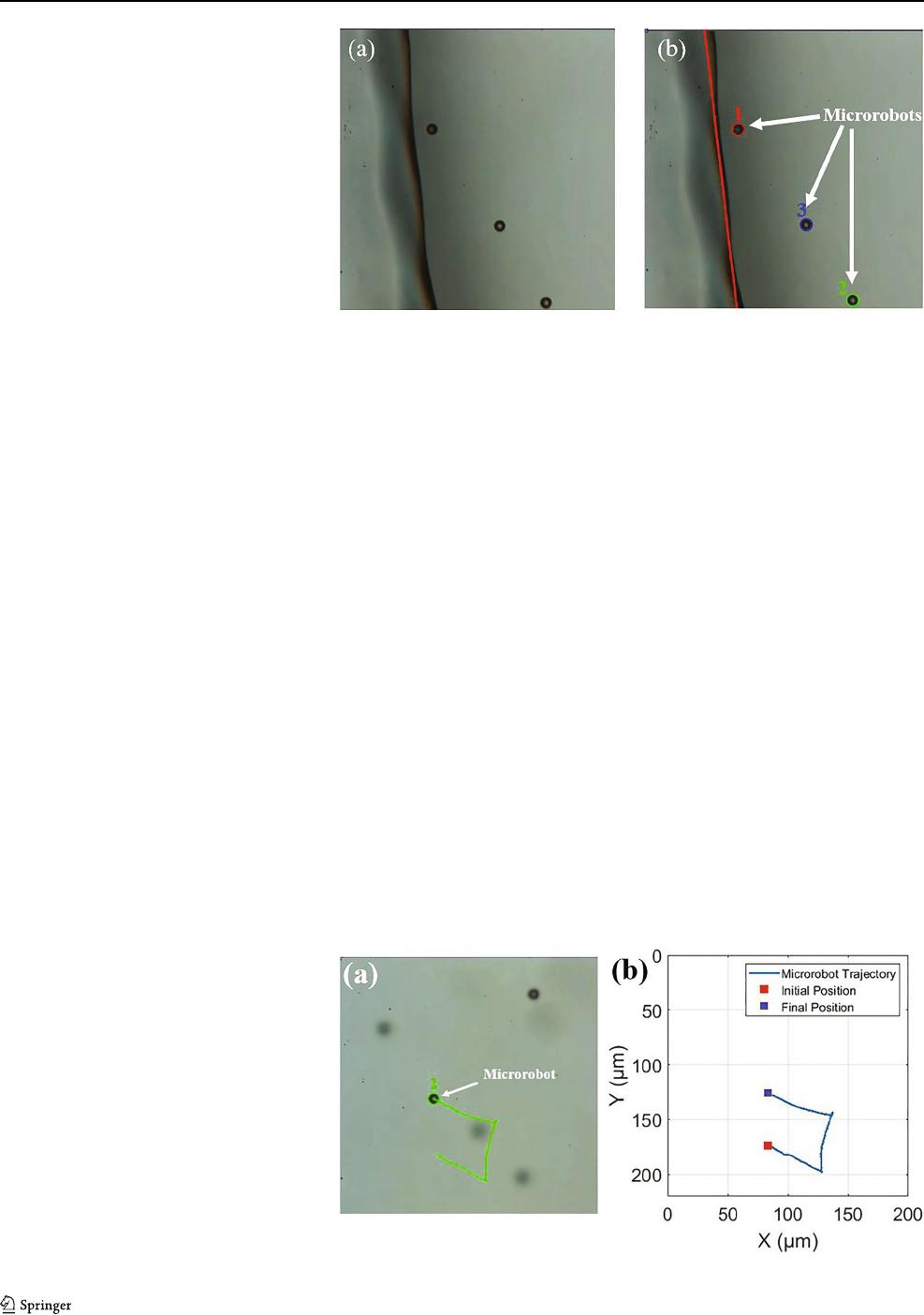

Fig. 5 Experimental results.a A

raw image of the video stream

depicting three microrobots and

an obstacle. b The detected

microrobots and the obstacle

using image processing

techniques

5 Experimental results

The experimental results section will be divided into four

parts: the first will discuss the experimental setup and

signal processing, the second will discuss the proposed

teleoperation scheme, where the haptic device will be used

to control the microrobot, the third will discuss the haptic

rendering of the environment, and the forth will discuss the

proposed teleoperation scheme with the haptic guidance to

track a desired path.

5.1 Experimental setup and signal processing

We used a magnetic tweezer system setup that was built

in house. The magnetic tweezer system was mounted

on an inverted microscope (Olympus IX50) with a 40X

microscope lens (Fig. 1). Each microrobot was made

from ferromagnetic microbeads (Spherotech SVFM-100-

4 Ferromagnetic Particle) with an average diameter of

10.6 μm. Subsequently, a population of microrobots, diluted

to 5% with 20% NaCl solution to minimize the aggregation

due to mutual magnetic attraction was also injected into

the PDMS (Polydimethylsiloxane) chamber. This chamber

was then placed in the center of the magnetic tweezer.

The purpose of 20% NaCl is to increase the density to

decrease particle sedimentation. Tween 20 was also added

to the solution in order to reduce the surface contact friction.

Tween 20 concentration is 10% and it is injected onto the

chamber surface before magnetic particle solution injection.

Volume ratio of magnetic particle solution and Tween 20

solution is 4:1 in the chamber.

The setup was designed such that the fluid was stationary,

so there would be no fluid flow in the inner chamber except

for the movement of microrobots. The control action was

restricted to a single bead of robots in the center o f the

chamber to avoid the drag forces due to the walls. Figure 5a

shows three microrobots and an obstacle. The positions

of the microrobots and the obstacle were estimated using

image processing techniques.

Image processing algorithms were used to estimate the

microrobot’s position from the video stream. We used a

circular Hough transform technique to detect the circles that

define the microrobots using phase coding [30]. The phase

coding is capable of estimating the center locations and radii

of the circles. We have added a filter tha limits the jumps

in position data to avoid sudden jumps in force feedback.

Additionally, the boundary can be modeled as a line for

visual and haptic rendering purposes. We extracted the line

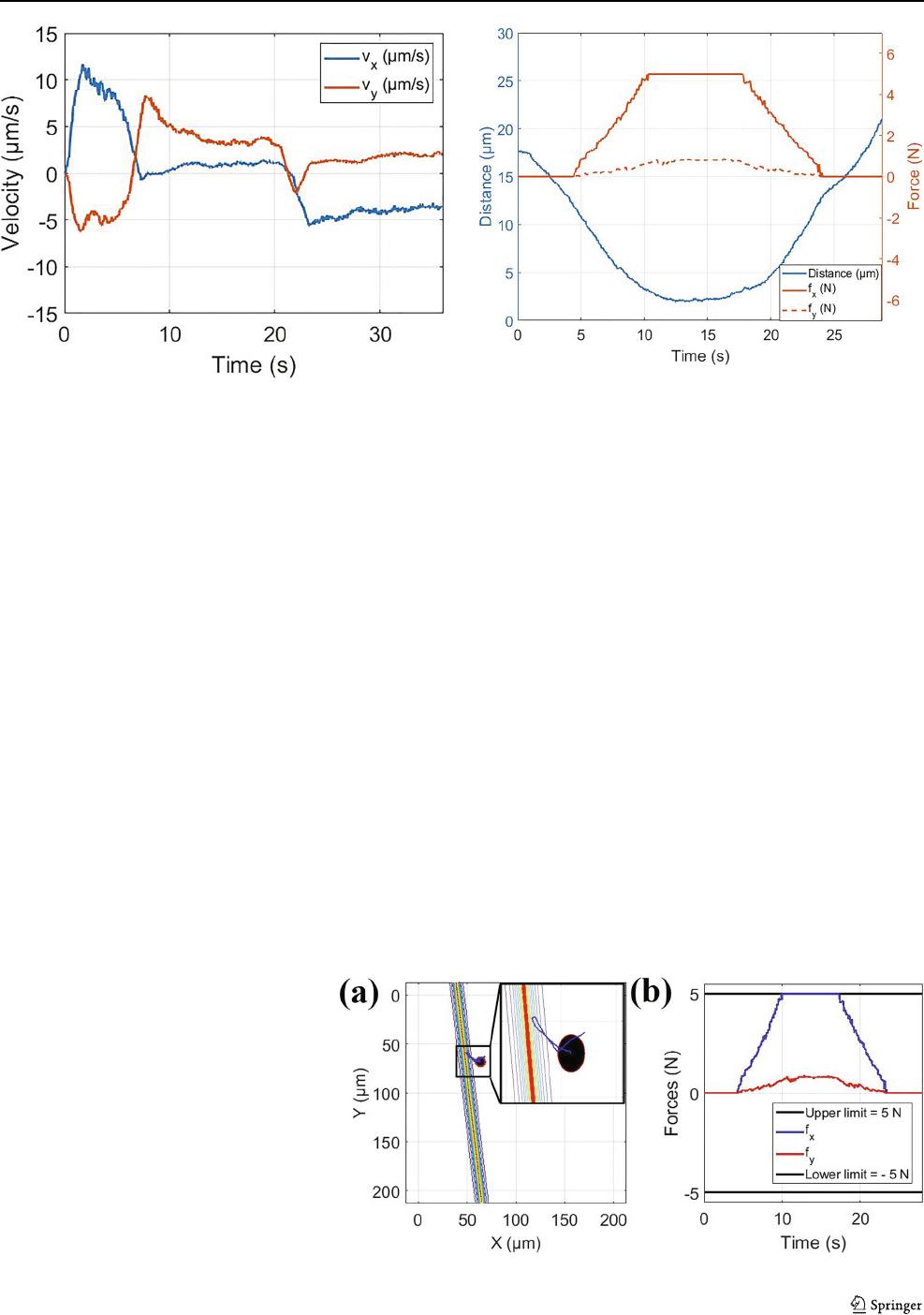

Fig. 6 Experimental results. a A

10 μm microrobot is controlled

using the haptic interface. b The

microrobot trajectory, initial,

and final position are shown

J Micro-Bio Robot

Fig. 7 Experimental results. Particle velocities according to the

applied magnetic gradients

segments from the streamed images based on a Hough

transform [31] to detect an obstacle in the environment.

Figure 5b shows the three detected microrobots, which were

labeled as 1, 2, and 3. The red line represents the obstacle.

Finally, transmission delays are negligible because data

are exchanged over a local network and the robots move

with relatively slow velocities.

5.2 Teleoperation control

An experimental test was performed using the teleoperation

control scheme described in Section 3. A simple task was

conducted to evaluate the proposed teleoperation method.

The operator used the Falcon haptic interface as a joystick

to move the microrobots. As expressed in Eq. 5,the

displacement of the haptic device was converted to desired

magnetic forces to be generated at the slave station.

Figure 6a shows how the task was carried out, where the

microrobot was labeled as 2. The microrobot trajectory in

the x - y plane is shown in Fig. 6b, where the red square

Fig. 8 Experimental results. a

Position of the microrobot with

respect to the obstacle. b The

forces in x and y directions that

are obtained using the potential

field algorithm

Fig. 9 Experimental results.The haptic forces and the distance

between the microrobot and obstacle as a function of time

represents the initial position, and the blue square represents

the final position. Figure 7 shows the microrobot velocities

according the the applied magnetic gradients.

5.3 Haptic rendering of the environment

In this section, an experimental test was performed using

the teleoperation control scheme with haptic rendering of

the environment as described in Section 4. With awareness

of obstacle locations, a grid map of the environment was

constructed. Figure 8a shows a contour representation of the

repulsive field due to an obstacle. Here, the influence range

of the obstacles is 10μm. Since we only have one haptic

interface, the operator can only feel the force acting on a

single robot. Thus, in this situation, microrobot (1) is the

microrobot of interest to be tracked and controlled by the

operator. Additionally, Fig. 8a shows the microrobot (1) and

its trajectory as the black circle and blue line, respectively.

The obstacle and its potential field are represented as a

red line with contour showing the area of influence of the

obstacle. As can be seen, the microrobot started from an

J Micro-Bio Robot

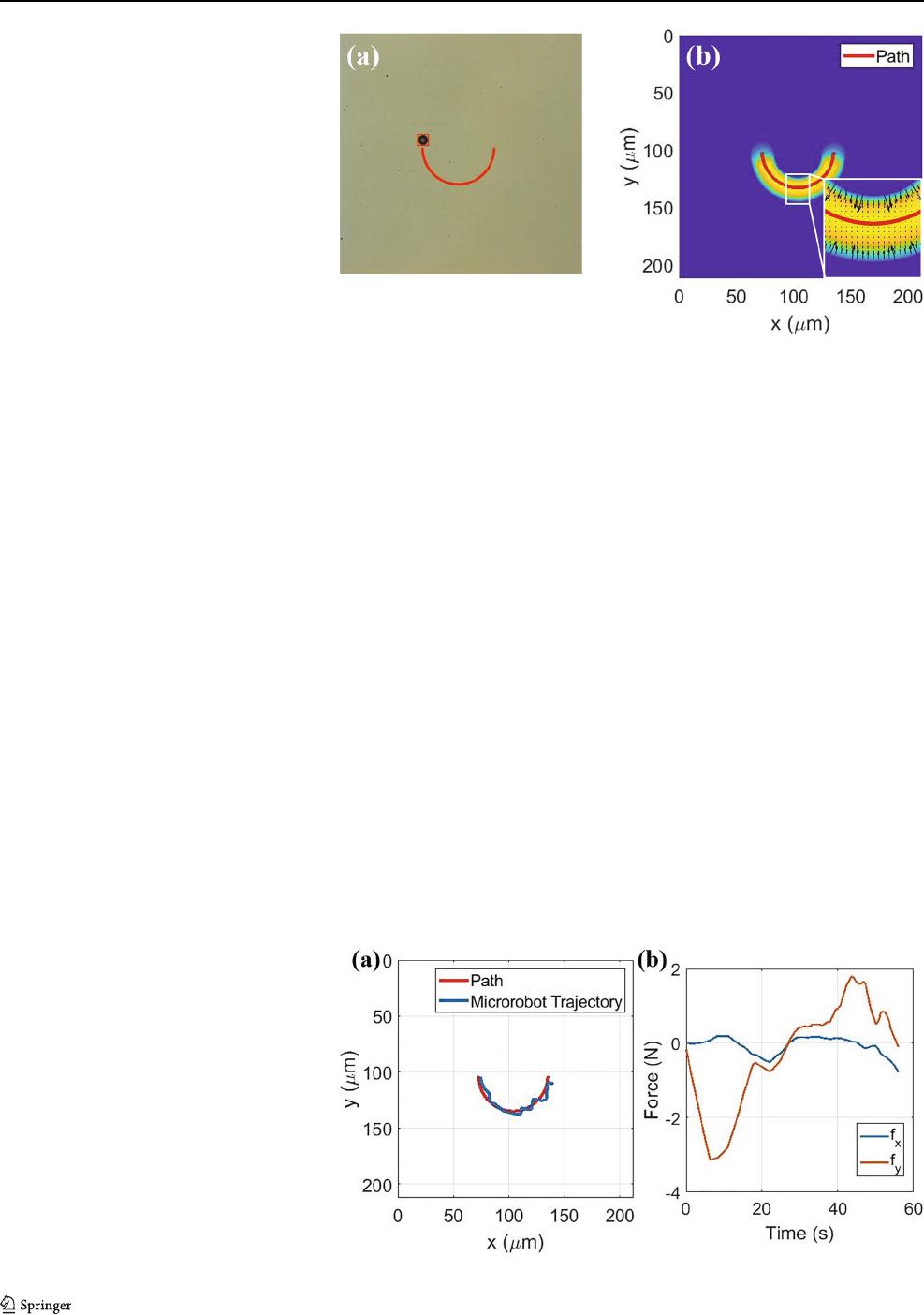

Fig. 10 Experimental results. a

A10μm microrobot is

controlled using the haptic

interface to follow a predefined

curved path. b The attractive

potential field around the path

initial location outside the influence region of the obstacle

potential field. As the operator move the microrobot in

the direction of the obstacle, the microrobot entered the

influence region, and the operator started to feel the forces

from the haptic device as shown in Fig. 8b. The blue

and red lines represent the forces in x and y directions,

respectively. The black lines represent the upper and lower

force limits of the Falcon haptic device. Also, as can be

seen from Fig. 8, the forces are proportional to the distance

between the microrobot and the obstacle. As the microrobot

approaches the obstacle, the operator felt stronger forces.

Finally, as the operator moved the microrobot away from

the obstacle, smaller forces were experienced until the

microrobot escaped the influence region of the obstacle.

Figure 9 indicates the haptic forces and the distance between

the microrobot and the obstacle as a function of time. The

blue line represents the distance, and the red and dashed red

represent the haptic forces in x and y directions.

5.4 Motion tracking

An experiment was carried out using the teleoperation

control scheme with the haptic guidance to track a desired

path. Five subjects took part in the experiment. In this

experiment, the microrobot locations are estimated using

the image processing techniques presented in Section 5.1.

Figure 10a shows the microrobot as well as the desired

path. An attractive potential field was g enerated using the

algorithm discussed in Section 4.2. The field is shown in

Fig. 10b, where the predefined path is represented as a

red line encircled by the attractive potential field. In this

experiment, the operator attempted to follow the path in

the presence of haptic guidance, as shown in Fig. 11a.

Figure 11b shows the haptic forces felt by the operator.

As can be seen, when the microrobot drifted away from

the path, the haptic algorithm guided the operator back to

it. Figure 12 indicates the haptic forces and the distance

between the microrobot and the desired path as a function of

time. The blue line represents the distance, and the red and

dashed red represent the haptic forces in x and y directions.

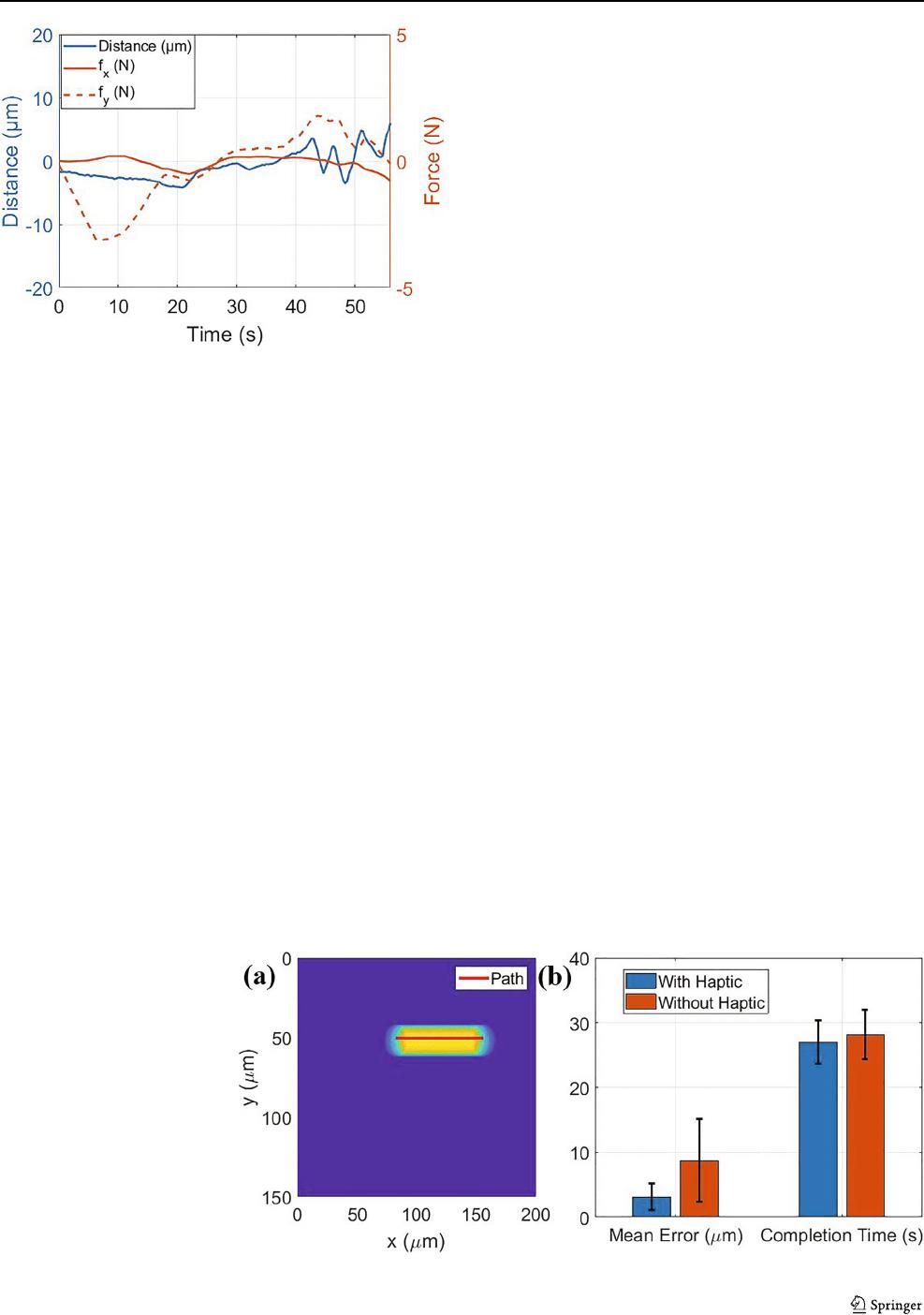

6 Validation

For benchmarking purposes, two groups of experiments

were carried out. In the first group, we attempted to move

Fig. 11 Experimental results. a

A predefined curved path and a

10 μm microrobot trajectories. b

The haptic forces, which

displaced to operator

J Micro-Bio Robot

Fig. 12 Experimental results.The haptic forces and the distance

between the microrobot and desired path as a function of time

a single microrobot along a predefined path without haptic

guidance. Then, this task was repeated with haptic guidance.

At each trial, we were able to follow the displayed path with

minimal error. Two criteria were selected to evaluate the

benchmark process: average path error and completion time.

The average path error was calculated as the mean of the

perpendicular distance between the microrobot position and

the path. The completion time was the time period between

the time instants the operator started tracking the path and

when the end of path was reached. In this experiment, five

subjects took part. They are males with age range of 25 to 35

years, and two of them were familiar with haptic feedback.

Each individual repeated each task three times. Using haptic

is intuitive, and based on our experiments, we observed that

the subjects who were not familiar with haptics caught up with

the ones who were familiar with it after a single trial. After

that the results of both groups were very similar. Never-

theless, even during the first trial the performance of the

subjects who were not familiar with haptics was improved

compared to their performance without the haptic interface.

Fig. 13 Validation Test. a A

10 μm microrobot is controlled

using the haptic interface to

follow a predefined straight

path. b The results of the

validation study show that

teleoperation with haptics in the

loop is significantly better than

with visual feedback only

The data obtained from these experiments are seemingly

better when haptic feedback is used. As can be seen in

Fig. 13, the average path error was reduced by a factor of

three, accompanied by a slight decrease in the completion

time. The slight improvement of the completion time was

due to the simplicity of the task. Finally, a paired t-test was

conducted to check if adding haptic feedback would result

in statistically significant improvements. The p-values are

computed as 0.065 and 0.37 for mean error and completion

time, respectively. The paired t-test does not exhibits strong

statistical evidence of improvement. This is probably due to

the relatively lower number of trials.

7 Conclusion

We developed a teleoperation setup for microrobots using

a haptic device and magnetic tweezers. In our setup, the

microrobot is virtually linked to the haptic device. Its

movements are controlled by the movement of the haptic

tool. To improve task performance, the guidance forces

are presented to the operator through the haptic interface

for better task performance. We conducted a basic set of

trials where we tracked a straight line segment using the

Falcon device with and without haptic guidance. The trials

showed that haptic guidance significantly improves tracking

errors but leads to modest benefits in task completion

time. Future work will aim at improving the teleoperation

system in more complex tasks. The Systems Lab at SMU

has been extensively engaged in haptic interface research

for more than a decade. The Pneumatic Haptic Interface

(PHI) was one of the first Haptic Interfaces developed [32–

35]. The PHI is an exoskeleton master arm with a 7-DOF

system. The exoskeleton applies the interaction forces with

the virtual/real environment to the right arm of the human

operator in order to render a force display. Another haptic

application in development is a glove [36, 37] that enables

the operator to feel ultrasound data. In our experiments we

J Micro-Bio Robot

always displayed the visual data to the users. We also relied

on user feedback during the present investigation because

our primary goal was to evaluate the contribution of haptic

feedback on user experience. In our future studies we will

investigate the effect of letting the users to complete their

tasks based on force feedback only. In addition, studying

the effect of using different haptic interfaces will be a good

topic of investigation.

The targeted applications for the present system is mostly

in the medical field. For example, one can preform micro-

surgeries and targeted drug delivery using microrobots to

improve accuracy by involving robotic devices. Haptics will

provide the medical personnel the power of intervention

and decision making during these operations. Giving the

surgeon control to guide the procedure will also have

positive affect on the public acceptance of this type of robot

assisted procedure.

Acknowledgments This work was funded by the National Science

Foundation (CMMI 1623324).

References

1. Gao W, Feng X, Pei A, Kane CR, Tam R, Hennessy C, Wang

J (2014) Bioinspired helical microswimmers based on vascular

plants. Nano Lett 14(1):305

2. Mertz L (2018) Tiny conveyance: micro-and nanorobots prepare

to advance medicine. IEEE Pulse 9(1):19

3. Cheang UK, Kim H, Milutinovi

´

c D, Choi J, Kim MJ (2017)

Feedback control of an achiral robotic microswimmer. J Bionic

Eng 14(2):245

4. Khalil IS, Pichel MP, Abelmann L, Misra S (2013) Closed-loop

control of magnetotactic bacteria. Int J Robot Res 32(6):637

5. Zhang X, Rogowski LW, Kim MJ (2020) Closed-loop control

using high power hexapole magnetic tweezers for 3d micromanip-

ulation. J Bionic Eng 17(1):113

6. Pacchierotti C, Scheggi S, Prattichizzo D, Misra S (2016) Haptic

feedback for microrobotics applications: a review. Front Robot AI

3:53

7. Tan HZ, Walker L, Reifenberger R, Mahadoo S, Chiu G, Raman

A, Helser A, Colilla P (2005) A haptic interface for human-in-

the-loop manipulation at the nanoscale. In: First joint eurohaptics

conference and symposium on haptic interfaces for virtual

environment and teleoperator systems. World haptics conference.

IEEE, pp 271–276

8. Schmid A, Yechangunja R, Thalhammer S, Srinivasan MA (2012)

Human-operated 3d micro-manipulator with haptic feedback.

In: 2012 IEEE Haptics symposium (HAPTICS) (IEEE 2012),

pp 517–522

9. Bhatti A, Khan B, Nahavandi S, Hanoun S, Gao D (2015) Intuitive

haptics interface with accurate force estimation and reflection

at nanoscale. In: Advances in global optimization. Springer,

pp 507–514

10. Pacchierotti C, Magdanz V, Medina-S

´

anchez M, Schmidt OG,

Prattichizzo D, Misra S (2015) Intuitive control of self-propelled

microjets with haptic feedback. J Micro-Bio Robot 10(1-4):37

11. Boukhnifer M, Ferreira A (2013) Fault tolerant control of

a teleoperated piezoelectric microgripper. Asian J Control

15(3):888

12. Ousaid AM, Bolopion A, Haliyo S, R

´

egnier S, Hayward V (2014)

Stability and transparency analysis of a teleoperation chain for

microscale interaction. In: 2014 IEEE International conference on

robotics and automation (ICRA) (IEEE 2014), pp 5946–5951

13. Ammi M, Ferreira A (2005) Realistic visual and haptic rendering

for biological-cell injection. In: Proceedings of the 2005 IEEE

International Conference on Robotics and Automation. IEEE

2005), pp 918–923

14. Asgari M, Ghanbari A, Nahavandi S (2011) 3d particle-based cell

modelling for haptic microrobotic cell injection. In: Proceedings

of the 15th International Conference on Mechatronics Technology,

Precision Mechatronics for Advanced Manufacturing, Service,

and Medical Sectors (ICMT 2011), pp 1–6

15. Seif MA, Hassan A, El-Shaer AH, Alfar A, Misra S, Khalil

ISM (2017) A magnetic bilateral tele-manipulation system

using paramagnetic microparticles for micromanipulation of

nonmagnetic objects. In: 2017 IEEE International conference on

advanced intelligent mechatronics (AIM), pp 1095–1102

16. Guix M, Wang J, An Z, Adam G, Cappelleri DJ (2018) Real-time

force-feedback micromanipulation using mobile microrobots with

colored fiducials. IEEE Robot Autom Lett 3(4):3591

17. Zhang X, Kim H, Kim MJ (2019) Design, implementation, and

analysis of a 3-d magnetic tweezer system with high magnetic

field gradient. IEEE Trans Instrum Meas 68(3):680

18. Purcell EM (1977) Life at low reynolds number. Amer J Phys

45(1):3

19. Al Khatib E, Bhattacharjee A, Razzaghi P, Rogowski LW, Kim

MJ, Hurmuzlu Y (2020) Magnetically actuated simple millirobots

for complex navigation and modular assembly. IEEE Robot

Autom Lett 5(2):2958

20. Zhang Z, Huang K, Menq CH (2009) Design, implementation, and

force modeling of quadrupole magnetic tweezers. IEEE/ASME

Trans Mechatron 15(5):704

21. Chen L, Offenh

¨

ausser A, Krause HJ (2015) Magnetic tweezers

with high permeability electromagnets for fast actuation of

magnetic beads. Rev Sci Instrum 86(4):044701

22. Chang L, Howdyshell M, Liao WC, Chiang CL, Gallego-Perez

D, Yang Z, Lu W, Byrd JC, Muthusamy N, Lee LJ et al

(2015) Magnetic tweezers-based 3d microchannel electroporation

for high-throughput gene transfection in living cells. Small

11(15):1818

23. Haber C, Wirtz D (2000) Magnetic tweezers for dna micromanip-

ulation. Rev Sci Instrum 71(12):4561

24. Bausch AR, M

¨

oller W, Sackmann E (1999) Measurement of local

viscoelasticity and forces in living cells by magnetic tweezers.

Biophys J 76(1):573

25. Zhang X, Rogowski LW, Kim MJ (2019) 3d micromanipulation of

particle swarm using a hexapole magnetic tweezer. In: IEEE/RSJ

International Conference on Intelligent Robots and Systems

(IROS). IEEE, pp. 1581–1586

26. Ishiguro Y, Takano W, Nakamura Y (2018) Bilateral remote

teaching and autonomous task execution with task progress

feedback. Adv Robot 32(6):311

27. Yang K, Lu C, Zhao X, Kawamura R (2017) From bead to

rod: Comparison of theories by measuring translational drag

coefficients of micron-sized magnetic bead-chains in stokes flow.

PloS One 12(11):e0188015

28. Pepe A, Chiaravalli D, Melchiorri C (2016) A hybrid teleoperation

control scheme for a single-arm mobile manipulator with

omnidirectional wheels. In: IEEE/RSJ International conference

on intelligent robots and systems (IROS), pp 1450–1455.

https://doi.org/10.1109/IROS.2016.7759236