Communications ,00.c

Liquid

Lattice Imperfections Studied by

16oo

X-Ray Diffraction in Deformed

Aluminum-Base Alloys: AI-Cu Alloy 4oo

o

o

S.K. CHATTOPADHYAY, S.K. CHATTERJEE, 300

and S.P. SENGUPTA

200

The present analysis is a continuation of the program

of study of lattice imperfections in deformed aluminum- f0o

base alloys. ~ Detailed X-ray diffraction study t2-6] has been

I ~ l

0

performed on aluminum-base copper alloys in four dif- 60

70

S0 90 100

ferent compositions, namely, 0.32, 0.84, 1.15, and

1.26 at. pct of Copper. The alloys were prepared from

spectroscopically pure ingredients supplied by Johnson-

Matthey Co. Ltd., London, by following the procedure

adopted in the preceding work of this series. [~] The alloys

were later homogenized at 530 ~ for 15 days in the face

centered cubic phase (Figure 1). The cold working was

achieved as usual by hand filling. A portion of the filling

from each alloy was annealed at 520 ~ to relieve the

stress so that the same be used as standard for the Stokes'

instrumental correction done earlier. The same proce-

dure tl] was followed to prepare a sample for the Siemens

Kristallofluex-4 X-ray diffractometer, and X-ray diffrac-

tion profiles were recorded by using CuK~ radiation. The

detailed line shift, line asymmetry, and line shape anal-

yses were performed by following the procedures and

using the equation mentioned used before. [1'4-s] The

microstructural parameters, like coherent domain sizes

(De),

microstrain (e~), stacking faults or', cz" (intrinsic

and extrinsic), deformation twin fault/3, dislocation den-

sity p, and stacking fault energy parameter 7//x, were

determined.

The line shift analysis was done by using the neigh-

boring peaks and considering the effects of lattice pa-

rameter change

Aa/ao

and intrinsic and extrinsic faulting

(a' - a"). The residual stress or in these alloy systems

was considered to be zero as it is considered for random

powder sample, t~'4-61 The values of lattice parameter

change

Aa/ao

which is due to dislocation arrangements

were found to be extremely small, indicating negligible

distortion of the lattice on cold work. The values of

(a' - a"), neglecting

Aa/ao,

were also calculated and

are shown in the Table I. The small values of (a' - a"),

almost within the error limits, show a negligible effect

of faulting. Unlike the AI-Ge system, t~] where a slight

indication of the faulting was observed at the higher con-

centration of Ge, this alloy system shows a negligible

effect of faulting even at higher concentration. This is

also evident from the negligible fluctuation of the lattice

Wt *]o At

Fig. 1 --The phase diagram of the AI-Cu system.

LI.26 oc,n~

4"05~~4~-

a

iii'.

o

4.01

4. oa

~.'o z:o

3!o 4'. o

Cos

0

Cot

9

Fig. 2--The plot of lattice parameter

am vs

extrapolation factor

cos 0 cot 0.

S.K. CHATTOPADHYAY, Lecturer, Department of Metallurgical

Engineering, and S.K. CHATTERJEE, Assistant Professor, Department

of Physics, are with the Regional Engineering College, Durgapur, India.

S.P. SENGUPTA, Professor and Head, is with the Department of

Materials Science, Indian Association for the Cultivation of Science,

Jadavpur, Calcutta, India.

Manuscript submitted January 22, 1991.

parameter

ahu vs the

cos 0 cot 0 curve around the fault-

free line t4,s,6J (Figure 2).

From peak asymmetry analysis, the compound fault

probability [4.5(ot") +/3] was determined and was found

to be low, even smaller than the AI-Ge system

(Table I). m The detailed Fourier line shape analysis t2-s]

was performed considering multiple reflections, and from

the Stokes' corrected Fourier coefficients (Figure 3), the

METALLURGICAL TRANSACTIONS A VOLUME 23A, APRIL 1992-- 1371

Table I. The Values of Effective Domain Sizes

(De),

Root-Mean-Square Strain (e~) ~/2, Compound

Fault Probabilities, (or' - ot'~), 4.5(ot") + fl, and [l.5(tt' + ~') + fl], and Individual Values of tt', el', and

(Q~t -- O~t,)

x 103

Line 4.5(a")

+

/3 x 104 1.5(a' + a")

Shift Line De (/k) + /3 x 103

Analysis Asymmetry (Error

Limit: (e~,/2 Line Shape

Alloy (Error Analysis ---5 to x 103 Analysis a' x 103 a" x 103

Compo- Limit: (Error Limit: (Error (Error (Error

sition +-2.0 CG -+0.003 -+ 10/~) at L = 50/~

= Limit: -+3.0 Limit: -+3.0 Limit: +-1.0

(At. Pet) to -+4.0) 20 = +-0.006 Deg) 111 100 111 100 to -+5.0) to +-10.0) to +-7.0)

/3

x

103

(Error

Limit: ---3.0

to +-20.0)

A1-0.32Cu -0.09 -1.2 574 320 0.8 1.4 10.0 -10.7 -9.1

A1-0.84Cu 2.8 -7.7 390 245 1.6 1.8 11.0 - 4.0 -8.2

Al-1.15Cu 7.0 -8.3 340 180 0.2 0.4 19.0 - 2.2 -8.4

A1-1.20Uu -0.06 4.9 470 278 0.6 3.2 10.5 - 6.2 -5.0

39.6

29.1

29.5

27.1

0"75

_

ro-i I i

AL- 0"32 uu

[a-200

-

r~-I I I

At- 1.26 ~u L.~, UL_. 0.

~0"50

0"25

F ~ 200

I I I i i i

0 50 I O0 150 200 250 300

L

(A*)

Fig. 3--Fourier coefficients AL vs L (/k) for (11 l) and (200) reflections for A1-0.32 at. pet Cu and AI-1.26 at. pct Cu alloys.

effective domain sizes, microstrain (e2), and compound

fault probability 1.5(a' + a") +/3 were determined and

are shown in Table I. The values of effective domain

sizes are found to be quite high and are of the same order

as those of the AI-Ge system. The root-mean-square strain

values are also found to be small as was found for the

A1-Ge system. Combining the results of line shift, line

asymmetry, and line shape analyses, the intrinsic, ex-

trinsic, and deformation twin fault densities were cal-

culated, and the values with their respective error limits

are shown in Table I. The values of intrinsic a' and ex-

trinsic a" are found to be small and negative, respec-

tively, indicating a negligible concentration of these two

faults even at a higher concentration of solute Cu. As

regards deformation twin/3, the fault parameter which

was found to be negative and absent in the A1-Ge system

appears to be slightly above error limit and positive. This

possible indication of the presence of twin fault in this

AI-Cu system, unlike A1-Ge, may be attributed to the

solute copper which has an inclination toward twinning.

The stacking fault energy parameter

7/Iz

and dislo-

cation density p were calculated by using the equations

mentioned in the earlier works.[4,s] The values of dislo-

cation density p for this alloy system are found to be

almost uniform for all alloy compositions and of the order

of -1 • 1011 cm/cm 3. The value of

7/tx

is also found

to be similar to that in the A1-Ge system,

i.e.,

of the

order of 3.0 x 10 -H cm. While the dislocation density

value (~1 • l0 ll cm/cm 3) is found to be much less than

that for copper-base gallium alloy tS] (20 • 1011), the

stacking fault energy parameter is found to be much

higher. When it is just -0.2 x 10-" cm for the Cu-Ga

system, it is 3.0 x 10 -H cm for this A1-Cu system.

Considering all of these observations, it may be con-

cluded that the A1-Cu system like pure aluminum and

the A1-Ge system tq investigated earlier is not prone to

1372--VOLUME 23A, APRIL 1992 METALLURGICAL TRANSACTIONS A

faulting. The indication of the onset of faulting at the

higher concentration of solute which was found in the

A1-Ge system is not observed in this alloy system. Though

no X-ray diffraction work on A1-Cu has been reported,

this observation is compatible with the electron micro-

scopic observation obtained on pure aluminum and with

the X-ray diffraction analysis done on other aluminum-

base alloy systems, t~

REFERENCES

1. S.K. Chattopadhyay, S.K. Chatterjee, and S.P. Sen Gupta:

Metall. Trans. A, 1990, vol. 21A, pp. 2597-98.

2. R.P.I. Adler and C.N.J. Wagner:

J. Appl. Phys., 1962, vol. 33,

pp. 3451-58.

3. J.B. Cohen and C.N.J. Wagner:

J. Appl. Phys., 1962, voi. 33,

pp. 2073-77.

4. S.K. Chatterjee, S.K. Halder, and S.P. Sen Gupta:

J. Appl. Phys.,

1976, vol. 47, pp. 411-19.

5. S.K. Chatterjee, S.K. Halder, and S.P. Sen Gupta:

J. Appl. Phys.,

1977, vol. 48, pp. 1442-48.

6. S.K. Chattopadhyay, S.K. Chatterjee, and S.P. Sen Gupta:

J. Phys. D, Appl. Phys., 1989, vol. 22, pp. 142-48.

7. M. De and S.P. Sen Gupta:

Pramana, 1984, vol. 23, pp. 721-44.

8. C.N.J. Wagner:

Local Atomic Arrangements Studied by X-ray Dif-

fraction,

AIME, New York, NY, 1966, vol. 36, ch. 6.

Diffusion Reaction in the

Zirconium-Copper System

K. BHANUMURTHY, G.B. KALE,

and S.K. KHERA

Diffusion reaction occurring between two solids plays

an important role in many metallurgical processes, such

as cladding, carborizing, and diffusion bonding. Inter-

diffusion in the zirconium-copper system has been stud-

ied in a limited temperature range of 873 to 977 K to

understand the compatibility between the two metals. The

only earlier work t~ in this system refers to isothermal

annealing at temperature in the vicinity of alpha-to-beta

phase transformation of zirconium. These results con-

firmed the formation of

CuaZr

and Cu3Zr in the diffusion

zone. In the present studies, detailed investigations of

the chemical diffusion in the zirconium-copper system

are reported.

Electron beam-melted zirconium (99.8 pct) ingots and

high-purity copper (99.9 pct) plates were roiled to thin

sheets of 3-mm thickness. Diffusion couples of

10 x 5 • 3 mm were prepared from fully annealed

(1173 K for 3 days) samples taken from these sheets.

The mating surfaces of zirconium and copper were pre-

pared by metallographic polishing up to 1-/xm diamond

finish. The polished faces of zirconium and copper were

kept in contact with each other and were loaded in a

specially made jig (at a pressure of 10 MPa) in order to

ensure intimate contact between two surfaces. The entire

assembly was placed in a vacuum furnace (10 -5 mm) for

diffusion bonding at 860 K for 10 minutes. The couples

thus prepared were sealed under helium atmosphere and

subsequently annealed in the temperature range of 873

to 977 K for periods between 0.5 and 20 hours in a pre-

heated resistance furnace controlling the temperature

within ___ 1 K with the help of a proportional controller.

The concentration penetration profiles across the pol-

ished sections perpendicular to the diffusion direction were

obtained on all of the couples. The electron probe micro-

analyses of the diffusion couples were carried out with

a stabilized beam current of 80 nA at 15 KeV. These

observed intensity ratios were corrected for atomic num-

ber, absorption, and fluorescence effects to get true con-

centrations, t21 Some of the diffusion couples were analyzed

at the interface by X-ray diffraction to confirm the stoi-

chiometry of the compound formed in the diffusion zone.

Diffusion coefficients were evaluated by both the

Boltzmann-Matano-Heumann and the Wagner methods

from the concentration penetration profiles. The details

of these two methods have been discussed elsewhere, t3m

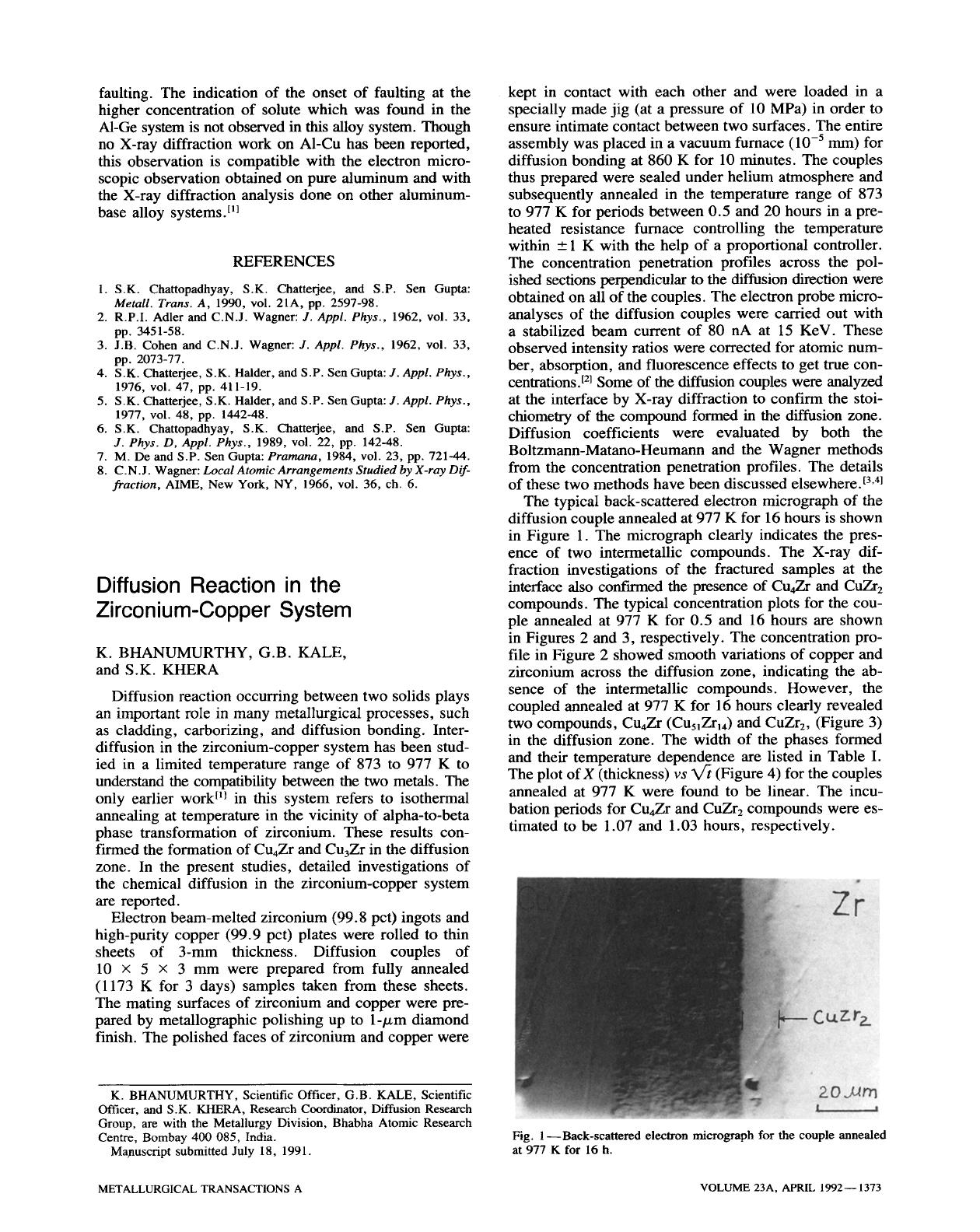

The typical back-scattered electron micrograph of the

diffusion couple annealed at 977 K for 16 hours is shown

in Figure 1. The micrograph clearly indicates the pres-

ence of two intermetallic compounds. The X-ray dif-

fraction investigations of the fractured samples at the

interface also confirmed the presence of Cu4Zr and

CuZr 2

compounds. The typical concentration plots for the cou-

ple annealed at 977 K for 0.5 and 16 hours are shown

in Figures 2 and 3, respectively. The concentration pro-

file in Figure 2 showed smooth variations of copper and

zirconium across the diffusion zone, indicating the ab-

sence of the intermetallic compounds. However, the

coupled annealed at 977 K for 16 hours clearly revealed

two compounds,

CugZr

(Cu51Zrl4)

and

CuZr2,

(Figure 3)

in the diffusion zone. The width of the phases formed

and their temperature dependence are listed in Table I.

The plot of X (thickness)

vs Vtt

(Figure 4) for the couples

annealed at 977 K were found to be linear. The incu-

bation periods for Cu4Zr and CuZr2 compounds were es-

timated to be 1.07 and 1.03 hours, respectively.

K. BHANUMURTHY, Scientific Officer, G.B. KALE, Scientific

Officer, and S.K. KHERA, Research Coordinator, Diffusion Research

Group, are with the Metallurgy Division, Bhabha Atomic Research

Centre, Bombay 400 085, India.

Ma)nuscript submitted July 18, 1991.

Fig. 1--Back-scattered eleclron micrograph for the couple annealed

at 977 K for 16 h.

METALLURGICAL TRANSACTIONS A VOLUME 23A, APRIL 1992--1373