1180

ISSN 1063-7788, Physics of Atomic Nuclei, 2018, Vol. 81, No. 8, pp. 1180–1186. © Pleiades Publishing, Ltd., 2018.

Original Russian Text © E.A. Gomin, V.D. Davidenko, O.V. Davidenko, A.A. Kovalishin, M.N. Laletin, A.K. Pavlov, 2017, published in Voprosy Atomnoi Nauki i Tekhniki.

Seriya: Fizika Yadernykh Reaktorov, 2017, No. 5, pp. 4–11.

DAREUS Software Package for Modeling the Dynamics of Solution

Reactors Using the Monte Carlo Method

E. A. Gomin

a

, V. D. Davidenko

a,

*, O. V. Davidenko

a

, A. A. Kovalishin

a

,

M. N. Laletin

a

, and A. K. Pavlov

a,

**

a

National Research Center Kurchatov Institute, pl. Kurchatova 1, Moscow, 123182 Russia

*e-mail: Davidenk[email protected]

**e-mail: Pavlo[email protected]

Received September 14, 2017

Abstract—The DAREUS software package designed for modeling dynamic processes in the cores of experi-

mental solution reactors is described. The KIR program based on the Monte Carlo method is used in the

package to compute the necessary kinetic parameters. The results of the calculations of some test cases are

given.

Keywords: computation, dynamics, kinetics, solution reactor, Monte Carlo method, supercomputer

DOI: 10.1134/S1063778818080100

INTRODUCTION

The DAREUS software package is designed for

computer simulation of dynamic processes in the

cores of solution reactors and is used at the Kurchatov

Institute for the computational support and computa-

tional modeling of the development of emergency

modes for the Gidra [1, 2] and Argus [1, 2] research

solution reactors.

The Gidra pulsed research reactor (PRR) was

developed and commissioned at the Kurchatov Insti-

tute of Atomic Energy (IAE) (now the National

Research Center Kurchatov Institute) in 1972. It

belongs to the class of self-quenching pulsed reactors,

the power pulse in which is quenched mainly owing to

the negative reactivity effect associated with the for-

mation of radiolytic gas fission fragments along the

tracks. The release of radiolytic gas from the fuel solu-

tion is accompanied by a rapid radiolytic boiling with

a sharp decrease in the fuel density (void reactivity

coefficient).

The reactor is designed to study the nature of radi-

ation defects in various materials in high-intensity

fields of reactor radiation, carry out activation analysis

of short-lived radionuclides, and also conduct

ampoule dynamic tests of fuel rods of various reactors

in the event of an accident with increasing reactivity.

The Argus research reactor (RR) was developed

and commissioned at the IAE in 1981. The reactor

operates at a steady-state power and is designed to f ind

the best physical and technical solutions for the devel-

opment of nuclear physics methods of analysis and

control and for the production of radionuclides for

medical purposes. Neutron activation analysis and

neutron radiography are performed at the Argus reac-

tor.

To date, the nuclear safety of these reactors has

been validated using software tools that make it possi-

ble to calculate the effects and coefficients of reactiv-

ity, other key reactivity characteristics, and the effi-

ciency of the control and protection system (CPS)

using the Monte Carlo method.

The DAREUS software package is the first one

that implements interconnected neutronic, thermo-

hydraulic, and thermomechanical calculations of the

dynamics of solution reactors.

1. DAREUS SOFTWARE PACKAGE

The DAREUS software package includes the KIR

neutronic calculation code [3], the GARD thermohy-

draulic calculation code, and the programming inter-

faces that connect them.

The computational modeling of a dynamic process

using the software package consists in the sequential

operation of the KIR and GARD programs. The total

dynamic process time is divided into a number of

intervals. It is assumed that the physical properties of

the reactor remain unchanged in each interval. Differ-

ent time grids can be used for programs of neutronic

and thermohydraulic calculations.

The KIR program from the DAREUS software

package makes it possible to preliminarily compute a

number of reactor states differing in the density of the

fuel solution, in the temperature of the materials, and

PHYSICS OF ATOMIC NUCLEI Vol. 81 No. 8 2018

DAREUS SOFTWARE PACKAGE 1181

in positions of control elements. To this end, the

DAREUS software package has a special computa-

tional module for determining the functionals

required for the GARD program.

This makes it possible to significantly reduce the

calculated dynamic process modeling time, and, if

necessary, the bank of computed states of the reactor

can be quite easily supplemented.

Apparently, this approach is optimal for the com-

putational studies of specific solution reactors, in par-

ticular, the Argus RR.

2. GARD PROGRAM

The most important problem in analyzing the

dynamics of solution RRs is to formulate a complete

system of equations for the dynamics of RRs that link

up heterogeneous transient processes of neutron,

molecular, thermomechanical, thermodynamic, and

hydrodynamic phenomena [4]. An extensive list of

original works in this field is given in the cited paper.

Specific features of the dynamics of solution RRs

are largely determined by the phenomenon of radio-

lytic boiling of the core, which requires a correct

description of the mechanism of formation (nucle-

ation) of bubble nuclei in the core solution, the pro-

cess of transport of radiolytic gas and heat, and the

general behavior of vapor-gas bubbles under steady

and unsteady pressures and temperatures.

The regular and most widespread model of the

mechanism of formation of bubbles by ionizing parti-

cles is generalized in the bubble chamber theory [4]. In

this model, a charged particle passing through water

creates a thermal track, a region of high temperature

along the trajectory of this particle. The thermal track

rapidly expands causing a pressure wave and then

decays into discrete regions of water vapor and radio-

lytic gas under the influence of surface tension. In the

superheated water or water supersaturated with gas,

these gas microbubbles can be centers of further

increase in the gas phase volume.

The GARD program is specially designed for mod-

eling thermomechanical and hydrodynamic processes

in solution reactors, including pulsed ones, in both the

nominal and emergency modes.

The solution of the system of equations for the

dynamics of solution reactors mentioned above is

implemented in it. The program consists of a set of

computational modules describing the heterogeneous

transient processes of the physical phenomena listed

above, which are characteristic of solution reactors.

The GARD program sequentially calls the neces-

sary calculation modules on the basis of the pre-

defined thermohydraulic reactor model. In this case, a

complete and mutually consistent system of equations

of dynamics is formed, after solution of which new

thermophysical functionals are transferred to the KIR

program for further neutronic calculation. These

functionals include the temperature of the structural

materials of the reactor and the density of the core

solution. Note that, when the density of the core solu-

tion changes, its volume also changes, which leads to a

change in the fill level. This change is taken into

account in the neutronic calculation of the next state

of the reactor in order to obtain the reactivity value.

In the current version of the GARD program, in

addition to the standard modules specific to reactors

of any type, computational modules are implemented

in which the following physical processes are simu-

lated:

1. Formation of bubbles of radiolytic gas in solution

as a result of the interaction of fission fragments with

water molecules.

2. Diffusion of radiolytic gas from bubbles into the

core solution.

3. Motion (ascent) of bubbles and release of radio-

lytic gas into the cavity above the core.

4. Change in the pressure in the cavity above the

reactor owing to the release of radiolytic gas from the

core and change in the fill level because of changes in

the density of the core solution.

5. Processes of heat exchange in the core taking

into account the heat removal through different chan-

nels: gas discharge and heat exchange with the vessel

and water coolant of circuit I.

6. Processes of heat and mass transfer in circuit II

and change in the level in the volume compensator of

circuit II.

7. Processes of heat exchange in the vessel and the

reflector.

Computational modules of the GARD program

make it possible to adequately describe the physical

processes in the solution reactor, in particular, the

processes associated with the introduction of positive

reactivity (burst).

3. KIR PROGRAM

The KIR program [3] is designed to solve the inho-

mogeneous stationary and nonstationary equations

and the homogeneous neutron transport equation by

analogous Monte Carlo methods based on the calcu-

lated nuclear data in systems with three-dimensional

geometry.

In the KIR program, the nonstationary neutron

transport equation is solved by the Monte Carlo

method with the time dependences of the positions of

the control elements and the densities and tempera-

tures of the materials of the structural elements.

Delayed neutrons are taken into account (those whose

precursors accumulated by the beginning of the simu-

lated time process and those that are formed during

the process). Note that, in addition to the standard set

of neutron flux functionals, the program makes it pos-

sible to calculate the effective fraction of delayed neu-

1182

PHYSICS OF ATOMIC NUCLEI Vol. 81 No. 8 2018

GOMIN et al.

trons and the effective lifetime of fission neutrons tak-

ing into account the importance function.

4. DAREUS SOFTWARE PACKAGE TEST

The DAREUS software package was verified with

respect to modeling the dynamics of solution reactors.

The results of modeling the dynamic processes are

presented below in order to illustrate the DAREUS

software package performance.

4.1. Gidra Reactor

The Gidra PRR belongs to the class of self-

quenching PRRs, the power pulse in which is

quenched mainly owing to the negative reactivity

effect associated with the formation of radiolytic gas

fission fragments along the tracks. The release of radi-

olytic gas from the fuel solution is accompanied by a

rapid radiolytic boiling with a sharp decrease in the

fuel density.

The core vessel is a steel cylinder with a hemispher-

ical bottom.

The internal diameter of the core vessel is 38.6 cm,

the height of the solution is 42 cm, and the working

volume is 40 L. The fuel is an aqueous solution of ura-

nyl sulfate UO

2

SO

4

enriched to 90%

235

U. The reactor

has no reflector. The longitudinal and cross sections of

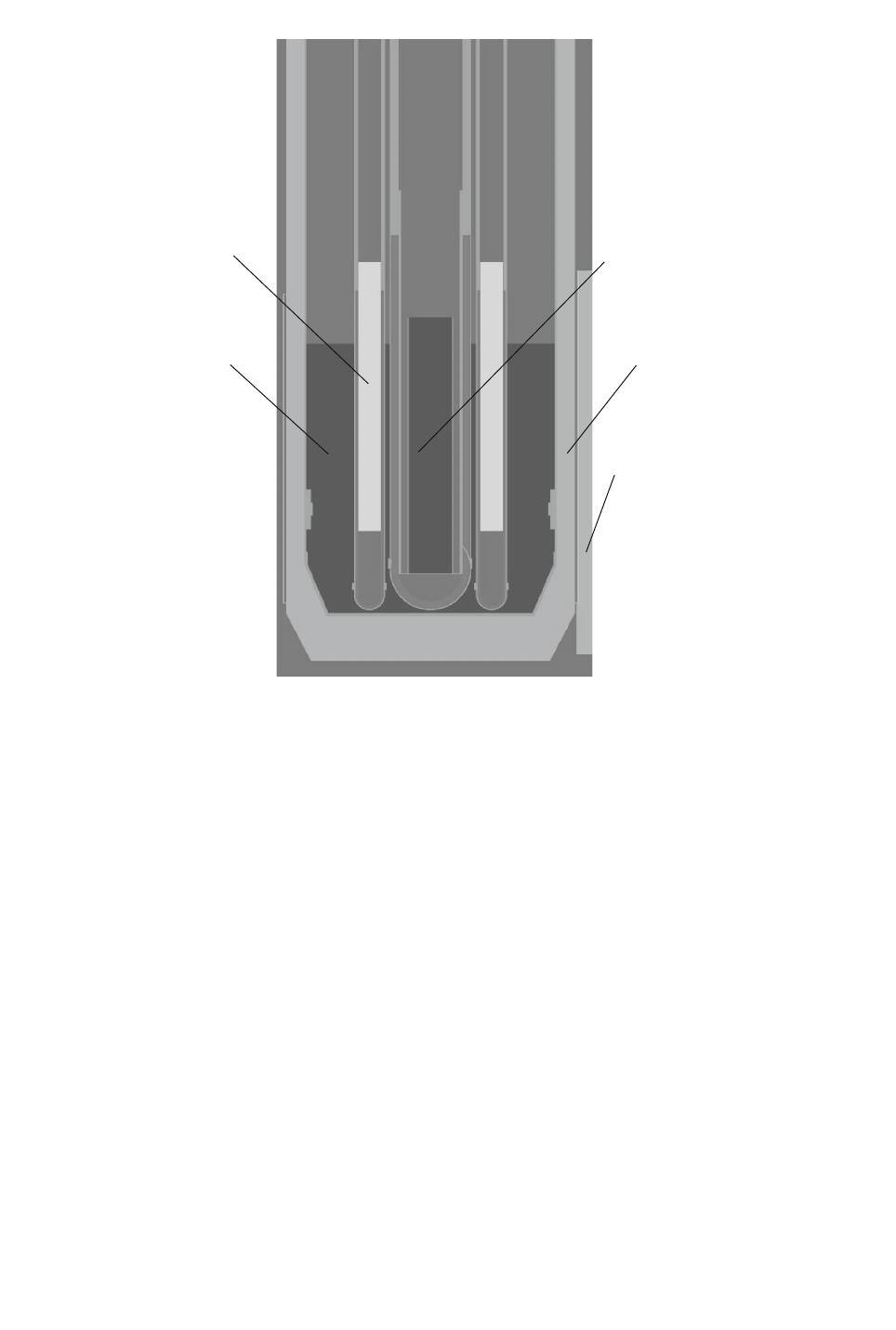

the core of the Gidra PRR are shown in Figs. 1 and 2.

The results of the calculations of dynamic pro-

cesses associated with the introduction of positive

reactivity due to the booster rod ejection using the

DAREUS software package are presented. They are

given in Fig. 3 in comparison with the experimental

data.

Let us consider the results of the calculations of

dynamic processes in the Gidra PRR in the case of the

introduction of positive reactivity in the interval of 1–

6 β

eff

. The results show that the differences between

the calculated and experimental values of energy

release at the time of the burst do not exceed 25% with

the introduction of positive reactivity in the interval of

1.5–4.5 β

eff

. A physical change in the process takes

place in the interval of 4.5–6 β

eff

: the increased energy

release creates inertial pressure of the solution (also on

the vessel lid) accompanied by the expansion of the

Fig. 1. Longitudinal section of the Gidra reactor and the positions of actuators. A group of actuators of reactivity compensators

is raised to an intermediate position.

Peripheral

channel

Fuel

solution

Central

channel

Vessel

Graphite column

portion

PHYSICS OF ATOMIC NUCLEI Vol. 81 No. 8 2018

DAREUS SOFTWARE PACKAGE 1183

solution. At the point corresponding to 4.5 β

eff

, the

calculated curve should change the inclination angle

and become steeper. The absence of this inflection

increases the difference between calculations and

measurements, which amounts to about 40% in the

interval of 4.5–6 β

eff

.

The results of the verification of the DAREUS

software package based on the data of pulsed experi-

ments conducted on the Gidra PRR made it possible

to conclude that the method of computational model-

ing of the processes occurring in the fuel solution and

associated with the formation and transport of bubbles

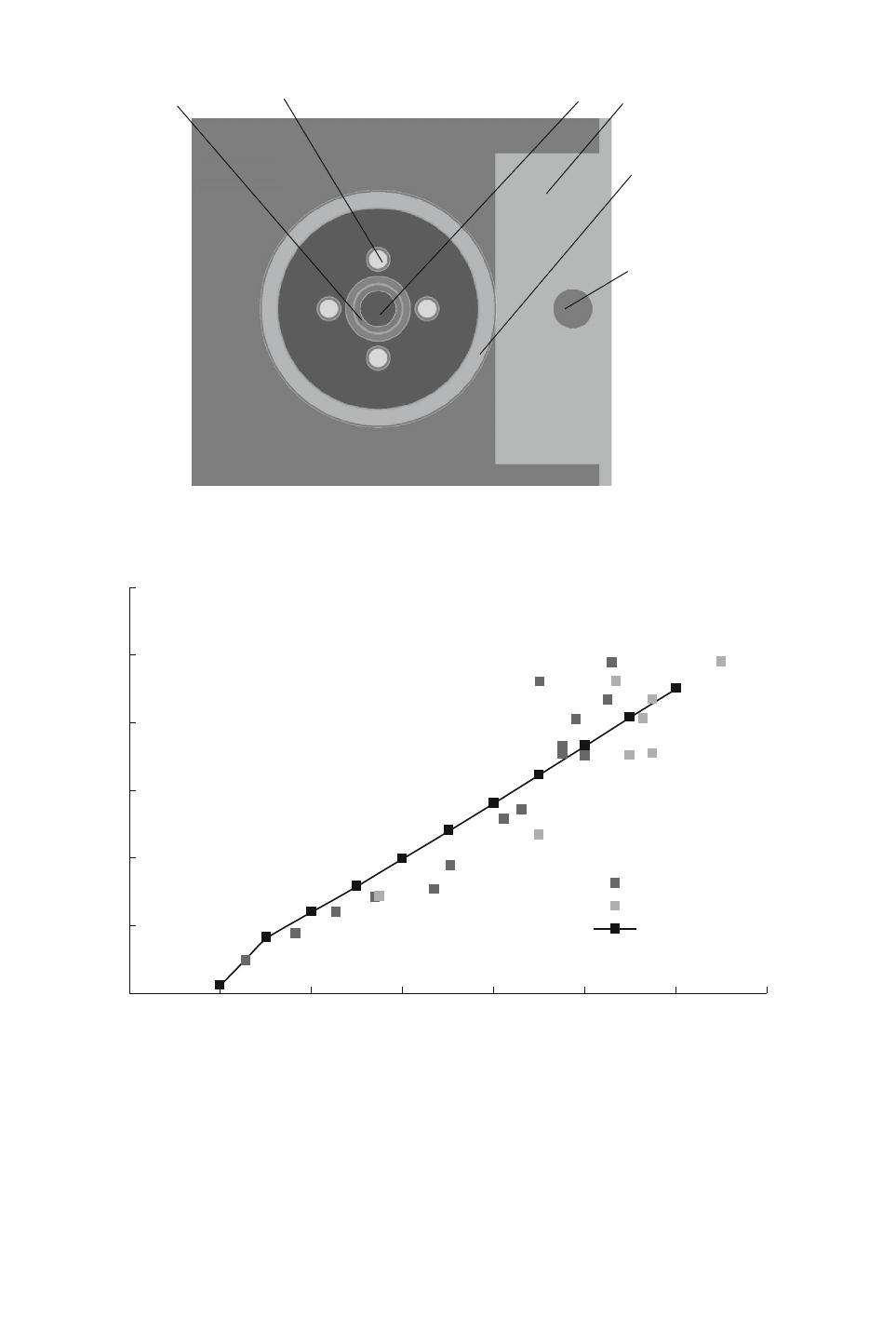

Fig. 2. Cross section of the Gidra reactor. The graphite column is partially shown.

Central

experimental

channel

Reactivity

compensator

Booster rod

Graphite column

Vessel

Experimental

channel

Fig. 3. Experimental and calculated maximum energy releases at the time of the burst depending on the initial reactivity jump

(KNK-57 is the neutron compensation chamber and PM is the photomultiplier).

20

40

60

80

100

120

KNK-57

PM

Calculation

1 2 3 4 5 6 70

Reactivity, β

e

Maximum energy release, MJ

1184

PHYSICS OF ATOMIC NUCLEI Vol. 81 No. 8 2018

GOMIN et al.

of radiolytic gas gives an acceptable calculated accu-

racy of the pulse power estimate.

4.2. Argus Reactor

The Argus RR operates at a steady-state power. By

design, it is very similar to the Gidra PRR.

The core vessel is a steel cylinder with a hemispher-

ical bottom.

The DAREUS software package was verified using

the experimental data obtained on the Argus RR with

highly enriched fuel (90%). The internal diameter of

the reactor vessel (core diameter) is 30.5 cm, the

height of the solution is 45 cm, and the working vol-

ume is 26 L. The fuel is an aqueous solution of uranyl

sulfate (UO

2

SO

4

). The reactor has a graphite reflector.

The coolant of circuit I is distilled water. The longitu-

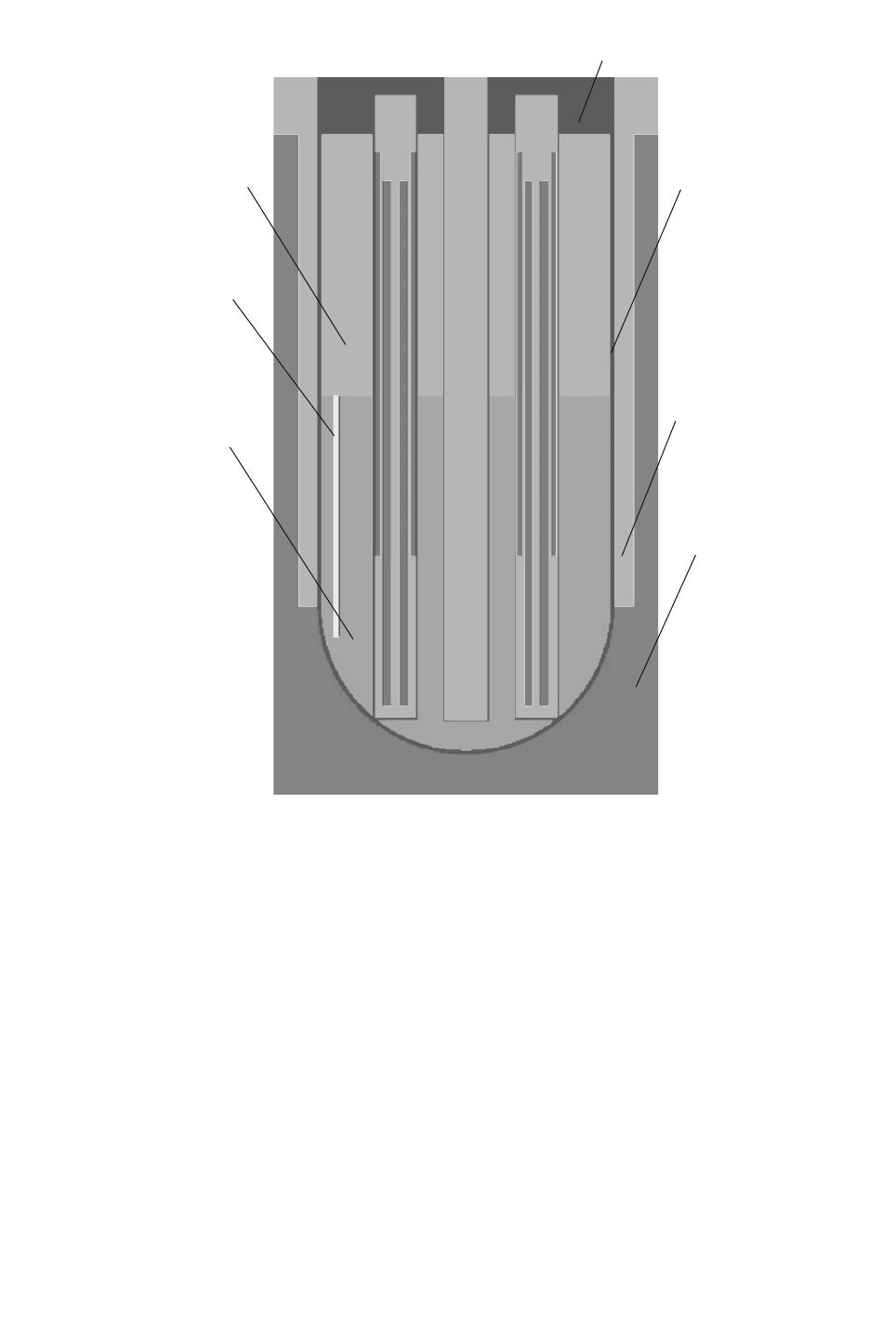

dinal and cross sections of the Argus core are shown in

Figs. 4 and 5.

The results of the DAREUS software package cal-

culations of the parameters of the RR Argus after the

shutdown of distillate circulation in the reactor cool-

ing system (RCS) (RCS pump shutdown) are pre-

sented. The experiment was carried out at a steady-

state reactor power of 20 kW. The temperature of the

fuel solution was about 80°C. As a result of the pump

shutoff, heat removal through the heat exchanger was

stopped. The temperature of the fuel solution and the

distillate in the coil started to rise. The temperature

increase added negative reactivity to the reactor, which

led to a drop in reactor power. For some time, the tem-

perature of the fuel solution stabilized around 100°C

owing to heat removal through the reactor vessel.

Fig. 4. Longitudinal cross section of the Argus reactor and position of the CPS actuator (A). A group of actuators of the safety

system (SS) is shown in an intermediate position.

Cavity over

solution

Coil tube

Fuel

solution

Lid

Vessel

Gap

Graphite

reflector

PHYSICS OF ATOMIC NUCLEI Vol. 81 No. 8 2018

DAREUS SOFTWARE PACKAGE 1185

Approximately 5 min after the pump shutoff, it was

switched on again. After some time, the reactor power

returned to the level of 20 kW (the automatic power

control system (APCS) was also turned on). The tem-

perature of the fuel solution also returned to the level

of 80°C.

When modeling this process using the DAREUS

software package, the reactor was brought to a power

of 20 kW, and after stabilization of the reactor param-

eters, the distillate circulation in the cooling system

was shut off. The RCS was turned on after about

6min.

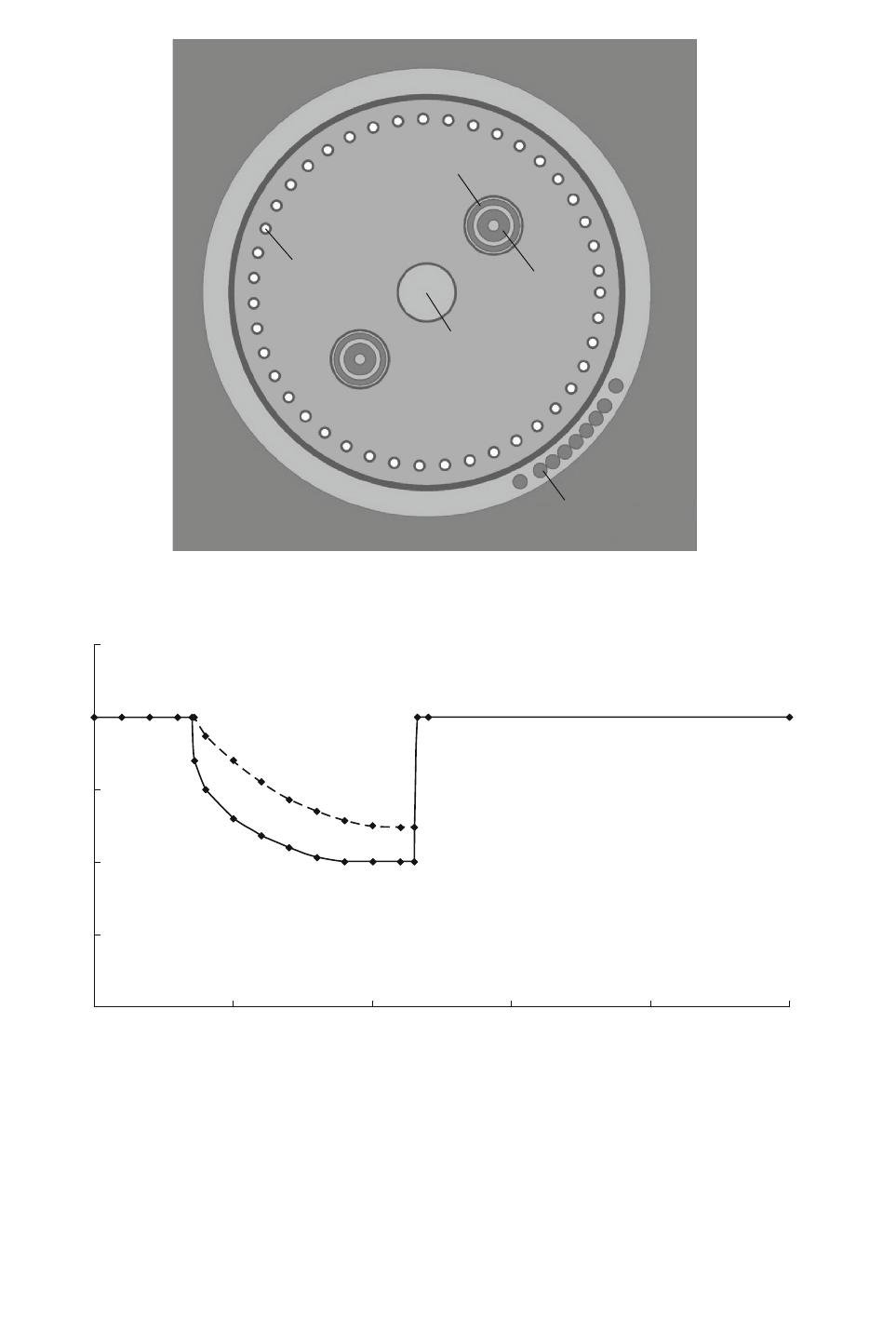

Fig. 5. Cross section of the Argus reactor.

SS

Cooling

coil

VC

Central

channel

External

regulating rods

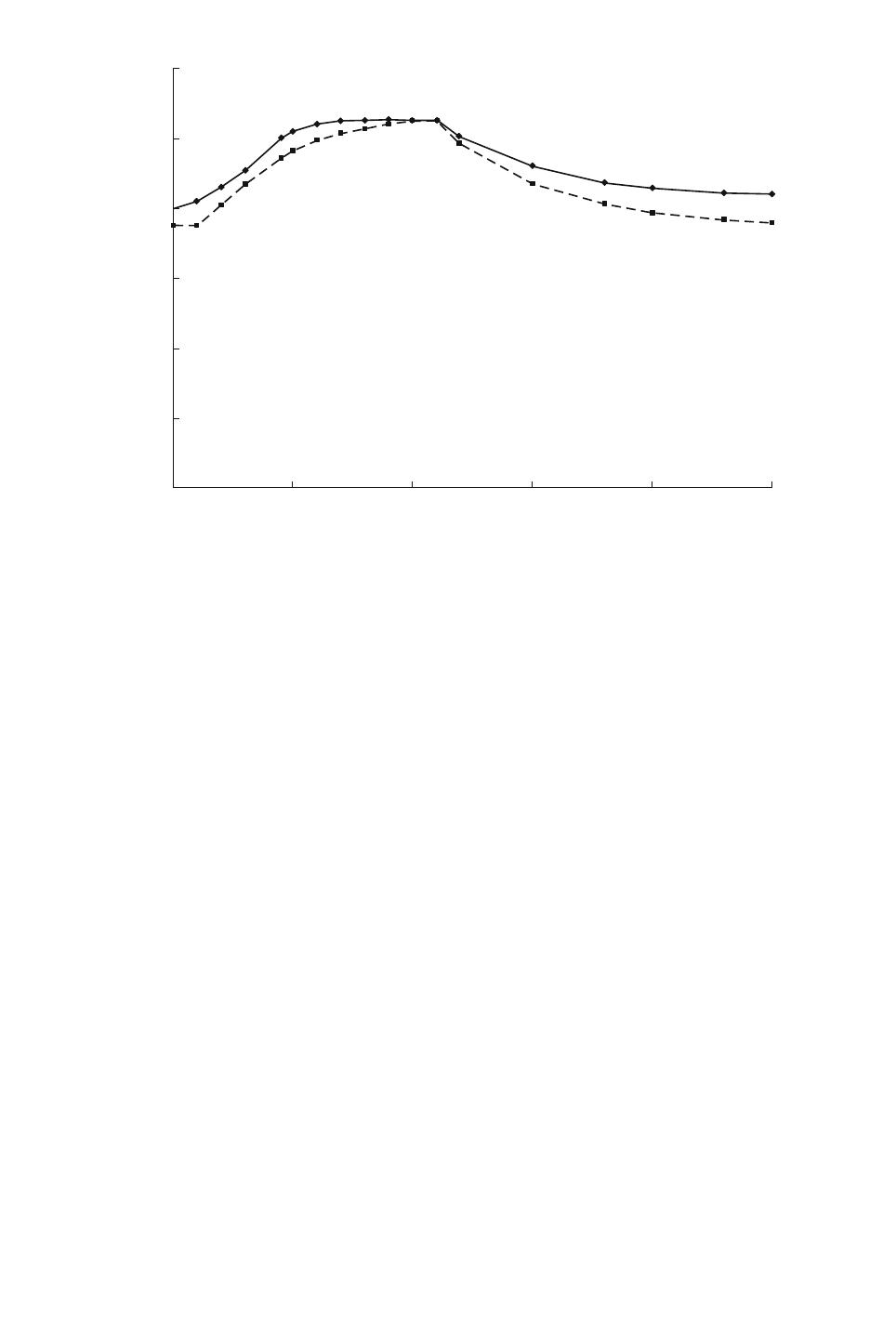

Fig. 6. Dependence of the reactor power on time when the RCS of circuit I is switched off and then switched on. The solid line

denotes experimental power values and the dotted line shows power values calculated using the DAREUS software package.

5

10

15

20

25

5 10 15 20 250

Time, min

Power, kW

1186

PHYSICS OF ATOMIC NUCLEI Vol. 81 No. 8 2018

GOMIN et al.

A comparison of the experimental and calculated

reactor power for the enabled and disabled RCS pump

is shown in Fig. 6. A comparison of the experimental

and calculated temperatures of the fuel solution are

given in Fig. 7.

CONCLUSIONS

The DAREUS software package designed for com-

puter modeling of dynamic processes in the cores of

Gidra and Argus solution RRs of the Kurchatov Insti-

tute complex of solution reactors is described.

The DAREUS software package implements inter-

connected neutronic, thermohydraulic, and thermo-

mechanical calculations of the dynamics of solution

reactors.

The DAREUS software package includes the KIR

neutronic calculation code based on the Monte Carlo

method, the GARD thermohydraulic calculation

code, and the programming interfaces that connect

them. The description of the codes is given.

The DAREUS software package performance is

illustrated by the results of the computational model-

ing and experimental data for two dynamic processes.

Their comparison demonstrates the efficiency of the

DAREUS software package.

REFERENCES

1. High-Temperature Nuclear Power Engineering. Unique

Developments and Experimental Base of the Kurchatov

Institute, Ed. by N. N. Ponomarev-Stepnoi (IzdAt,

Moscow, 2008) [in Russian].

2. Research Nuclear Facilities of the CIS Member States,

Ed. by M. K. Vinogradov and V. N. Fedulin (Gelios

ARV, Moscow, 2016) [in Russian].

3. E. A. Gomin, V. D. Davidenko, A. S. Zinchenko, and

I. K. Kharchenko, Vopr. At. Nauki Tekh., Ser.: Fiz.

Tekh. Yad. Reakt., No. 5, 4 (2016).

4. V. F. Kolesov, Aperiodic Pulsed Reactors (RFYaTs-

VNIIEF, Sarov, 1999) [in Russian].

Translated by O. Pismenov

Fig. 7. Dependence of the temperature of the fuel solution of the reactor on time when the APCS and pump of the RCS of circuit I

are switched off and then switched on (the solid line denotes the experimental temperature values and the dotted line shows the tem-

perature values calculated using the DAREUS software package).

20

40

60

80

120

100

5 10 15 20 250

Time, min

Temperature, °C