Vol.:(0123456789)

1 3

Topics in Catalysis

https://doi.org/10.1007/s11244-020-01401-0

ORIGINAL PAPER

Radial Basis Function Neural Network Model Prediction ofThermo-

catalytic Carbon Dioxide Oxidative Coupling ofMethane to C

2

-

hydrocarbon

BamideleVictorAyodele

1

· SitiIndatiMustapa

1

· ThongthaiWitoon

2

· RameshKanthasamy

3

·

MohammedZwawi

4

· ChieduN.Owabor

5

Accepted: 17 November 2020

© Springer Science+Business Media, LLC, part of Springer Nature 2020

Abstract

Various anthropogenic activities often result in the emission of carbon dioxide (CO

2

), which is one of the principal compo-

nents of greenhouse gases responsible for greenhouse effect. One vital strategy to mitigate the effect of the released CO

2

on

the environment is through sustainable utilization and conversion to value-added chemicals. This study employs the Radial

Basis Function artificial neural network for modeling the prediction of thermo-catalytic CO

2

oxidative coupling of methane

to C

2

-hydrocarbons. The various architecture of the Radial Basis Function ANN was developed, trained, and tested using

the non-linear relationship between the input parameters (reaction temperature, amount of CaO and MnO in the CaO-MnO/

CeO

2

catalysts and the CO

2

/CH

4

ratio) and the output parameters (C

2

hydrocarbon selectivity and yield). The Radial Basis

Function ANN architecture with the topology of 4-20-2, representing the input layer, hidden neurons, and the output layer

offers the best performance with a sum of square error (SSE) of 3.9 × 10

−24

for training and 0.224 for testing. The R

2

of 0.989

and 0.998 obtained for the prediction of the selectivity and the yield of the C

2

hydrocarbon is an indication of the robustness

of the Radial Basis Function ANN model. The sensitivity analysis revealed that the input parameters significantly influence

the model output. However, the reaction temperature has the most significant influence on the model output based on the

level of importance.

Keywords Artificial neural network· Carbon dioxide utilization· Radial basis function· Oxidative coupling of methane·

C

2

hydrocarbon

1 Introduction

Sustainable utilization of carbon dioxide (CO

2

) to mitigate

its effect on the environment has been the focus of research-

ers in the past decades [1–3]. CO

2

together with methane

are the major constituents of greenhouse gases which are

the main causes of greenhouse effect [4]. The Paris agree-

ment on climate change has given the mandate to reduce

greenhouse gas emissions by at least 40% by 2030 [5]. In

view of this, researchers have investigated various strate-

gies such as the recommendation of appropriate policies to

reduce CO

2

emissions, the use of renewable energy sources,

and the sustainable utilization of greenhouse gases to pro-

duce value-added chemicals [6, 7]. Several technological

processes such as CO

2

reforming of methane, CO

2

hydro-

genation, CO

2

methanation, and CO

2

oxidative coupling

of methane have been investigated [8–13]. CO

2

reforming

of methane and CO

2

hydrogenation arethermo-catalytic

* Bamidele Victor Ayodele

1

Institute ofEnergy Policy andResearch, Universiti Tenaga

Nasional, Jalan IKRAM-UNITEN, 43000Kajang, Selangor,

Malaysia

2

Center ofExcellence onPetrochemical andMaterials

Technology, Department ofChemical Engineering,

Faculty ofEngineering, Kasetsart University Bangkok,

Bangkok10900, Thailand

3

Chemical andMaterials Engineering Department,

Faculty ofEngineering Rabigh, King Abdulaziz

University, Rabigh Branch, P.O. Box344, Rabigh21911,

KingdomofSaudiArabia

4

Mechanical Engineering Department, Faculty ofEngineering

Rabigh, King Abdulaziz University, Rabigh Branch,

P.O. Box344, Rabigh21911, KingdomofSaudiArabia

5

Department ofChemical Engineering, Federal University

ofPetroleum Resources, Effurun, DeltaState, Nigeria

Topics in Catalysis

1 3

conversion processes that focus on the production of syn-

gas and methanol [7, 14]. Whereas CO

2

oxidative coupling

of methane focuses on the production of C

2

hydrocarbons

which are important chemical intermediates for several pro-

cess industries [15]. As shown in Eqs. (1) and (2), CO

2

is

employed as an oxidant in the methane coupling reaction

to produce C

2

H

6

and C

2

H

4

, respectively. Although the pro-

duction of C

2

hydrocarbons is the main focus of the CO

2

oxidative coupling of methane, side reactions could also lead

to the production of syngas as shown in Eqs. (3) and (4).

Hence, appropriate catalysts are needed to drive the selectiv-

ity of the C

2

hydrocarbon formation.

C

2

hydrocarbons are widely used as chemical build-

ing blocks most especially in the production of rubber

and plastics [16]. Moreover, ethylene which is one of the

C

2

-hydrocarbons can be used as anesthetic, oxy-fuel gas

used for welding and fabrication as well as a refrigerant

[17]. As shown in Fig.1, several catalysts have been inves-

tigated in the CO

2

oxidative coupling of methane. The find-

ings revealed that the catalysts displayed a high selectivity

to C

2

hydrocarbon with a very low yield. To overcome the

challenges of low C

2

hydrocarbon yield in CO

2

coupling

of methane reaction, Istadi, and Amin [18] employed a

response surface technique to optimize the process condi-

tions. At optimum condition, the selectivity of 76.56% and

a yield of 3.74% were obtained from the thermo-catalytic

(1)

2CH

4

+ CO

2

⇌

C

2

H

6

+ CO + H

2

O

(2)

2CH

4

+ 2CO

2

⇌

C

2

H

4

+ 2CO + H

2

O

(3)

2CH

4

+ 2CO

2

⇌

2CO + 2H

2

(4)

CH

4

+ 3CO

2

⇌

4CO + 2H

2

O

CO

2

oxidative coupling of methane. Besides using response

surface techniques, a data-driven predictive model can be

employed to investigate how the various input parameters

influence the C

2

selectivity and yield [19]. The parameter

estimates from the model can be used as a basis in deciding

on how to design a CO

2

oxidative coupling reactor that could

maximize the yield.

An artificial neural network (ANN) is a robust technique

that can be employed to develop a data-driven predictive

model [20–23]. ANN has been employed in modeling vari-

ous chemical processes resulting in an excellent predic-

tion of the process output [24]. Ehsani etal. [25] employed

Levenberg–Marquardt trained multilayer perceptron neural

network for modeling the prediction of ethylene production

over Mn/Na

2

WO

4

/SiO

2

catalyst based on the non-linear rela-

tionship between the input parameters (reaction temperature,

CH

4

/O

2

ratio, the concentration of N

2

and gas hourly space

velocity) and the output parameters (selectivity and yield of

ethylene). The optimized 4-9-1 and 4-6-1 ANN topology

were robust in predicting the selectivity and yield of the

ethylene produced from the oxidative coupling reaction. In

a similar study, Ehsani etal. [26] employed the use of Lev-

enberg–Marquardt trained multilayer perceptron neural net-

work and genetic algorithm to model the oxidative coupling

of methane for C

2

hydrocarbon production. A minimum

prediction error obtained from the model is an indication

of appropriately to understand the non-linear relationship

between the input parameters and the output parameters.

Also, Huang etal. [27] employed ANN and hybrid genetic

algorithms to model catalyst design for the oxidative cou-

pling of methane. The models efficiently aided the design

of a multi-component catalyst for methane oxidative cou-

pling resulting in a higher yield of C

2

hydrocarbon. Istadi

and Amin [28], employed a hybrid ANN and genetic algo-

rithm for modeling and optimization of non-catalytic plasma

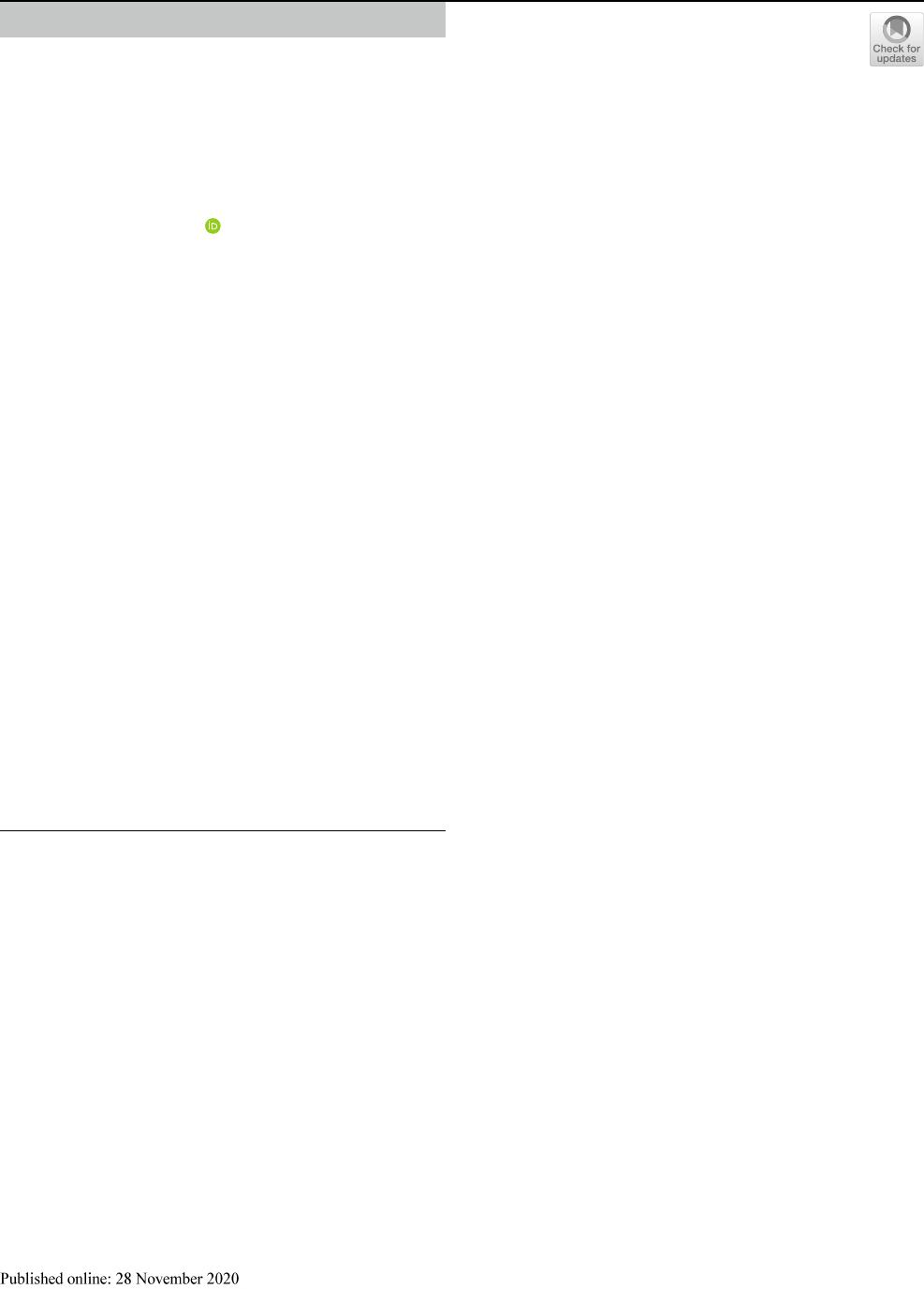

Fig. 1 Selectivity and yield of

C

2

hydrocarbon obtained from

CO

2

coupling of methane over

various catalysts

0

10

20

30

40

50

60

70

80

90

100

C

2

hydrocarbon

Catalysts

selecvity (%) yield (%)

Topics in Catalysis

1 3

reactor used for the production of C

2

hydrocarbon. The find-

ing shows that the hybrid ANN and genetic algorithm was

robust in modeling the effect of CH

4

/CO

2

feed ratio, total

feed flow rate, and discharge voltage on the C

2

hydrocarbon

production. In all these studies, it can be seen that multilayer

perceptron neural network was employed for modeling the

oxidative coupling of methane using oxygen as oxidant. The

use of Radial Basis Function ANN for modeling CO

2

oxi-

dative coupling of methane to C

2

hydrocarbon is lacking in

literature. Hence, the main focus of this study is to employ

Radial Basis Function ANN for modeling C

2

hydrocarbon

production by CO

2

oxidative coupling of methane using the

non-linear relationship between the input parameters (reac-

tion temperature, amount of CaO in the catalyst, amount

of MnO in the catalyst and CO

2

/CH

4

ratio) and the output

parameters (selectivity and yield of the C

2

hydrocarbon).

Compared to the multilayer perceptron neural network, the

radial basis function offers the advantage of better generali-

zation, not a complicated design, strong tolerance to input

noise, and ability to adapt to online learning.

2 Thermo‑catalytic Carbon Dioxide

Oxidative Coupling ofMethane

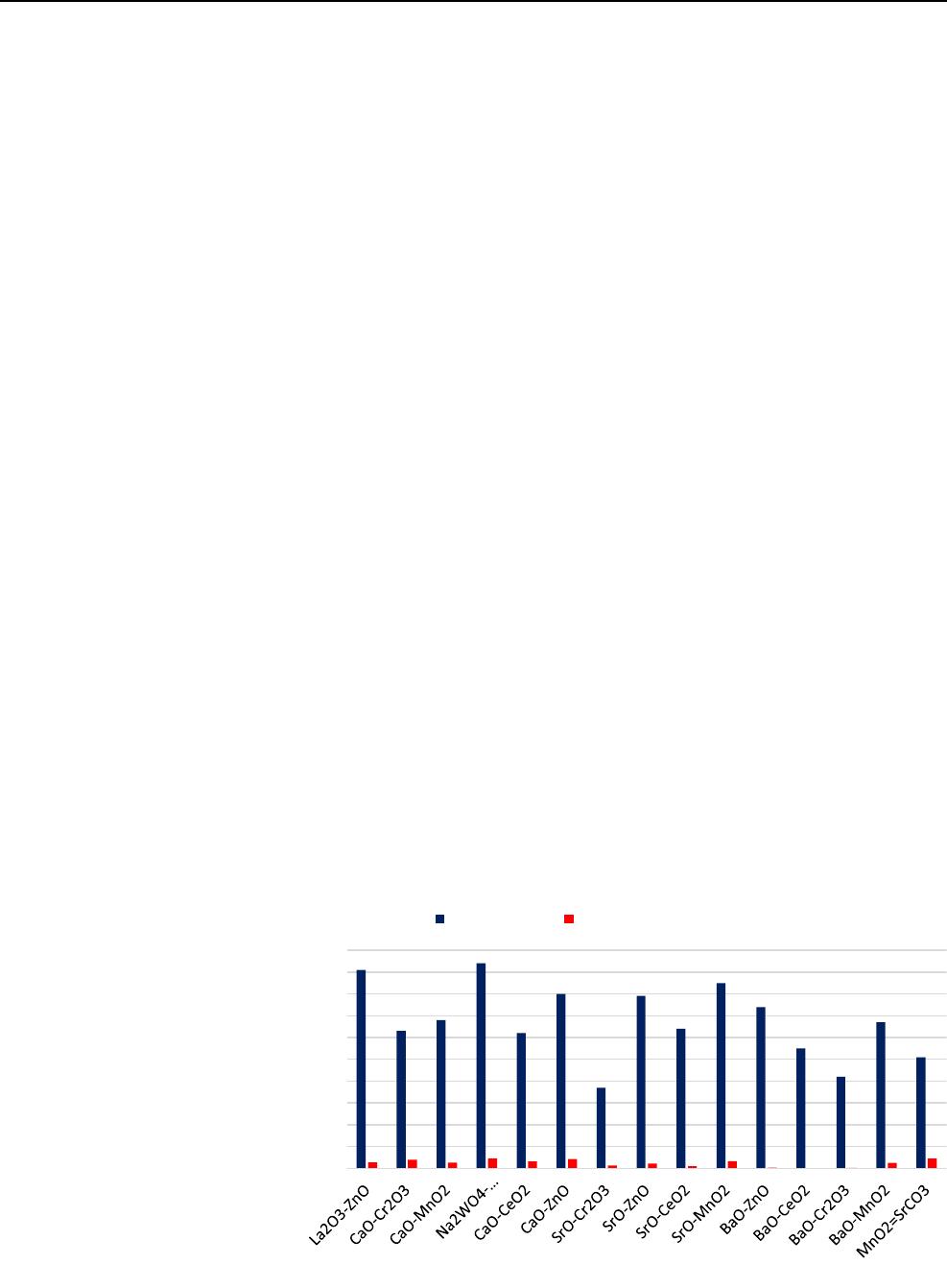

The Conceptual representation of the Radial Basis Func-

tion ANN modeling of the thermo-catalytic CO

2

oxidative

coupling of methane to C

2

-hydrocarbon is depicted in Fig.2.

The detailed description of the experimental design and

runs have been reported in Istadi and Amin [18]. The CO

2

oxidative coupling of methane was performed over CaO-

MnO/CeO

2

catalyst [18]. The experiment was designed

using four input parameters namely reaction temperature

(700–1000°C), amount of CaO in the catalyst (5–25mol%),

amount of MnO (1–9mol%) in the catalyst, and CO

2

/CH

4

ratio (1–3) and two output parameters namely selectivity and

yield of the C

2

hydrocarbon. The experimental design con-

sists of 26 treatment combinations of the four input param-

eters. For each of the runs, the data of the input parameters

were set to obtain the corresponding output parameters.

These data were subsequently employed for the Radial Basis

Function ANN modeling.

2.1 Radial Basis Function ANN Modeling

andSensitivity Analysis

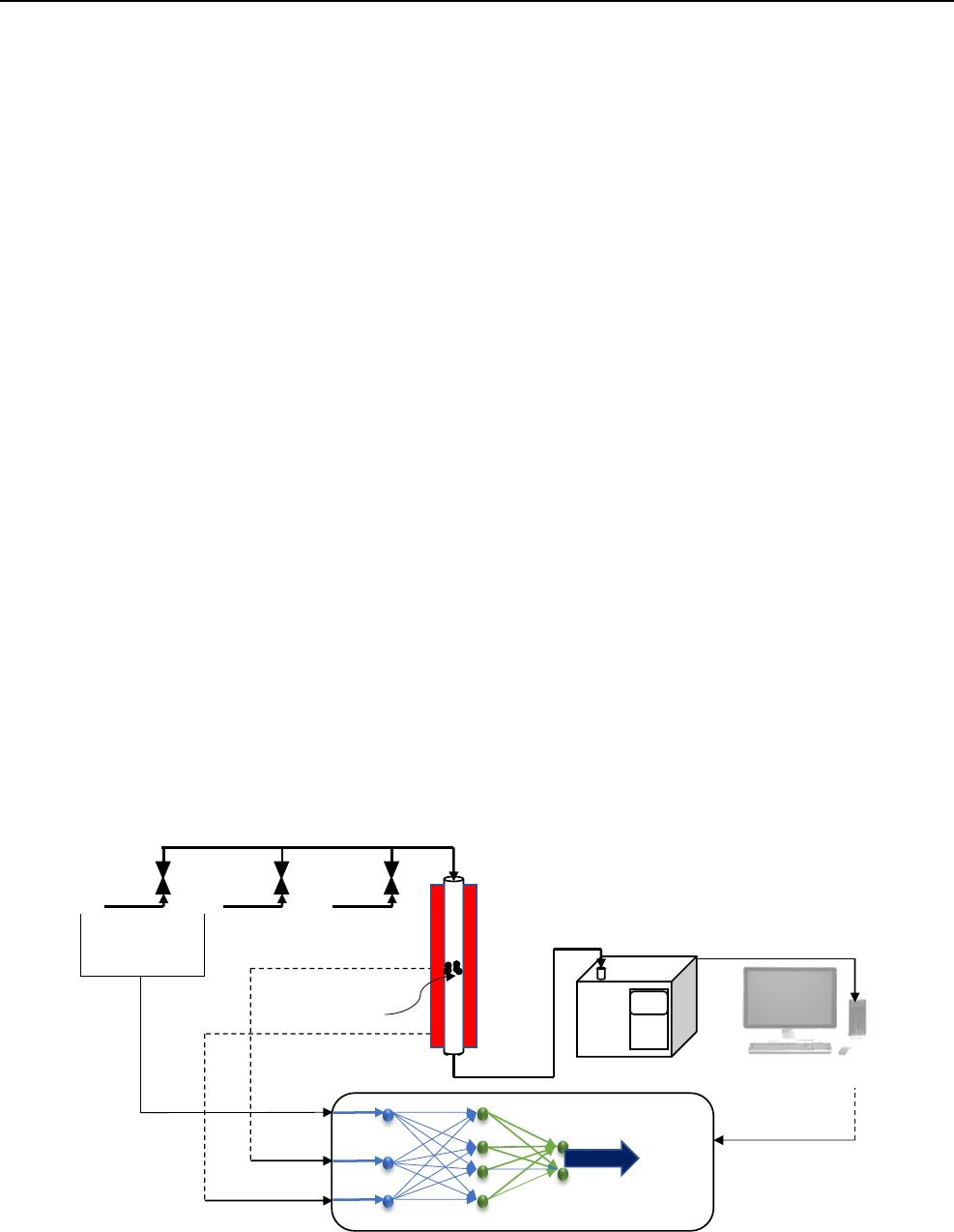

Radial Basis Function is an ANN technique that works based

on the principle of function approximation [29]. As shown in

Fig.3, the Radial Basis Function ANN consists of three lay-

ers namely the input layer, hidden layer, and the output layer

[30]. In the input layer, each variable is linked with an inde-

pendent neuron. The input layers facilitate the propagation

of the input vector into the hidden layer for detail configu-

ration [22]. Each of the input vector (x) is associated with

corresponding weight (w). At the hidden layer, the intercon-

nections of the Radial Basis Function units as well as biases.

Each of the Radial Basis Function units is associated with a

Gaussian Kernels. The most relevant input neuron to be used

for the hidden layer configuration was determined using the

Softmax activation function which have offers a range value

between 0 and 1. At the hidden layer, a non-linear transfor-

mation mathematically represented in Eq. (5) is perform by

comparing the Euclidean distance of the input vector (x) and

the Gaussian function center (cj).

GC-TFC-FID

CO

2

CH

4

N

2

Catalyst

CO

2

/CH

4

ratio

Temperature

Amount of catalyst

Model Predicted

C

2

hydrocarbon

Fig. 2 Conceptual representation of the neural network model prediction of thermo-catalytic carbon dioxide oxidative coupling of methane to

C

2

-hydrocarbon

Topics in Catalysis

1 3

where h

j

, x, c

j

and represents the j-th neuron in the hid-

den layer, the input vector, Gaussian function center, and

the width.

The output layer consists of the output vector y

k

which

is computed based on the summation of the input vectors

weights (w

kj.

) and the biases (b

k

) as shown in Eq. (6). The

activation function was used to determine the appropriate

hidden neurons that can be used to compute the output

function.

In order to obtain optimum performance of the Radial

Basis Function ANN, the network is often trained to adjust

itself by performing parameter estimates of hidden neu-

rons based on the weights and biases that could result in

the best output. In the present study, to prevent over-fitting,

the 26 data set was partitioned into two in the proportion

of 70% for training and 30% for testing the models. The

performance of the Radial Basis Function ANN model

was measured using the sum of square errors (SSE) which

measures the actual deviation of the predicted values from

observed values as well as the coefficient of determina-

tion (R

2

) which measures the proportion of variance of

the model outputs that can be explained by the input

parameters. The Neural Network toolbox by International

(5)

(6)

y

k

(x)=

nh

∑

j=

1

w

kj.

h

j

(x)+b

k

Business Machine (IBM) corporation was used for config-

uring the Radial Basis Function ANN model.

The influence of the input parameters on the Radial Basis

Function ANN model output in terms of the relative impor-

tance was investigated using Garson Algorithm [31]. The

sensitivity analysis of the model is useful in helping to make

decisions on the most significant input parameters that have

the greatest influence on the output. The Garson Algorithm

employed the absolute value of partitioned input-hidden and

hidden-output weights of the trained Radial Basis Function

ANN model to select the most significant input parameters.

3 Results andDiscussion

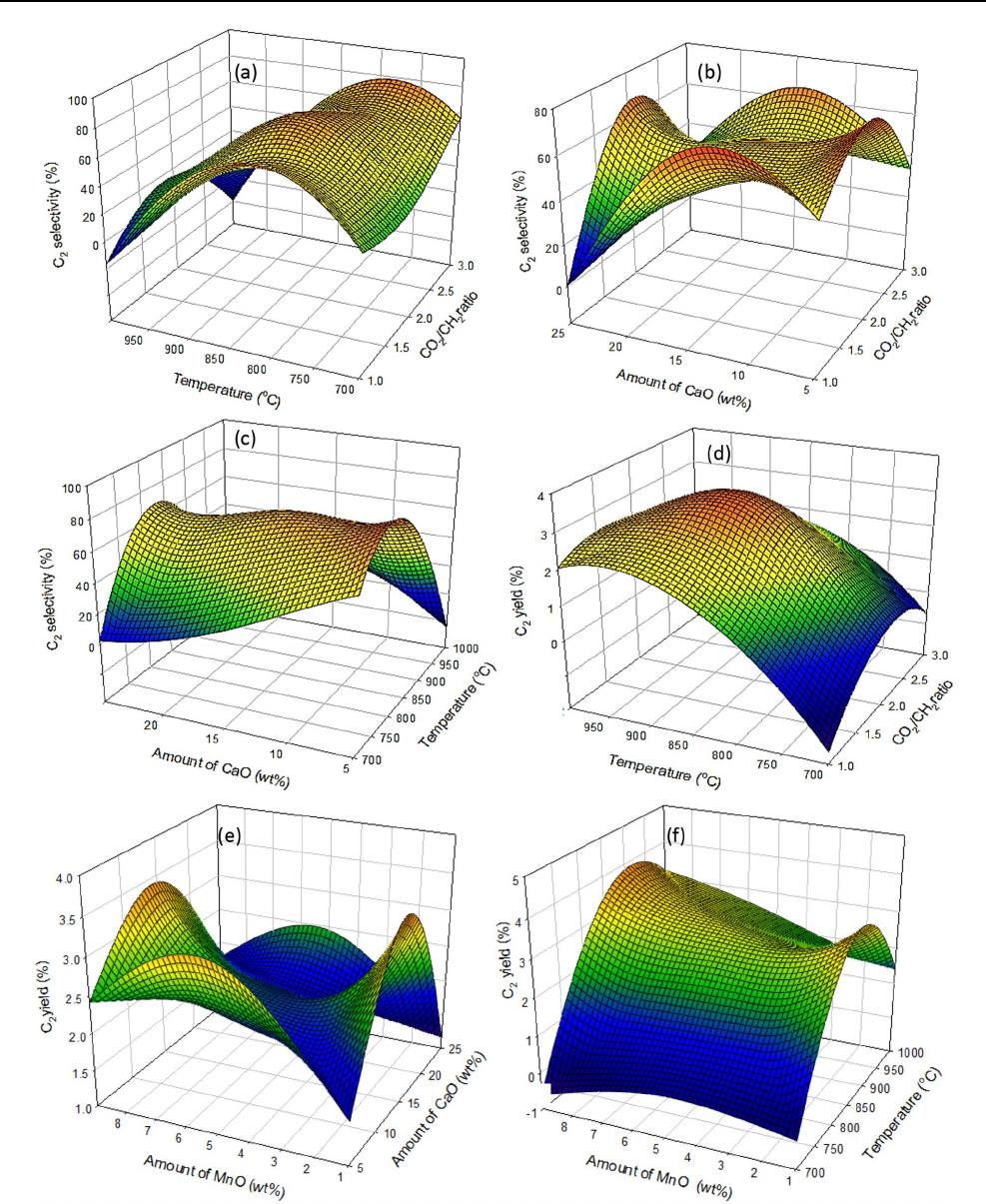

3.1 Interaction Eects oftheProcess Parameters

The effect of parameters such as gas hourly space velocity,

CH

4

/O

2

ratio, reaction temperature, N

2

flow rate, and the

amount of catalyst on the selectivity and yield of C

2

hydro-

carbon obtained from the oxidative coupling of methane has

been investigated. Based on the study reported by Istadi and

Amin [18], reaction temperature, CO

2

/CH

4

ratio, amount

of CaO in the catalyst, amount of MnO in the catalyst, and

CO

2

/CH

4

ratio were reported to influence the selectivity and

yields of C

2

hydrocarbon at optimum conditions. The three-

dimensional plots showing the interaction effects of the reac-

tion temperature, CO

2

/CH

4

ratio, amount of CaO in the cata-

lyst, amount of MnO in the catalyst, and CO

2

/CH

4

ratio on

the selectivity and yields of C

2

hydrocarbon are depicted in

Fig. 3 The Radial Basis Func-

tion ANN model architecture

1

2

3

Bias

Topics in Catalysis

1 3

Fig. 4 Interaction effect of (a) temperature and CO

2

/CH

4

ratio (b)

Amount of CaO and CO

2

/CH

4

ratio (c) Amount of CaO and tempera-

ture on C

2

selectivity; Interaction effect of (d) Temperature and CO

2

/

CH

4

ratio (e) CO

2

/CH

4

ratio and Amount of MnO (f) CO

2

/CH

4

ratio

and temperature on C

2

yield [18]

Topics in Catalysis

1 3

Fig.4. It can be seen that there is an existence of a non-linear

relationship between the input parameters and the output

parameters which makes the data most suitable for mod-

eling the process using the Radial Basis Function ANN [32].

As shown in Fig.4a andf, an increase in the reaction tem-

perature of the CO

2

oxidative coupling of methane reaction

resulted in a corresponding increase in the selectivity and

yields of the C

2

hydrocarbon until it peaked at 850°C and

gradually decrease at temperature >850°C. For a thermo-

catalytic reaction, it is expected that the yield and selectivity

of the products increase with an increase in temperature.

However, the deactivation of the catalysts could set in dur-

ing the reaction thereby reducing the catalytic activity [33].

Also, the increase in the amount of catalysts and the CO

2

/

CH

4

ratio depicted in Fig.4b–e were also observed to have

varying effects on the C

2

hydrocarbon selectivity and yields.

The yield and selectivity of the C

2

hydrocarbon increase

with an increase in the CO

2

/CH

4

ratio until 2 and thereaf-

ter decreased. As the concentration of CO

2

increased in the

reactant mixture, a parallel CO

2

disproportion reaction might

set in thereby converting some of the CO

2

to carbon which

could invariably deactivate the catalyst [34]. Increasing the

components of each of the catalysts was also observed to

increase the yield and selectivity of the C

2

hydrocarbon as

shown in Fig.4band c. However, the MnO dopant were

found to have a negative influence at an amount >15%.

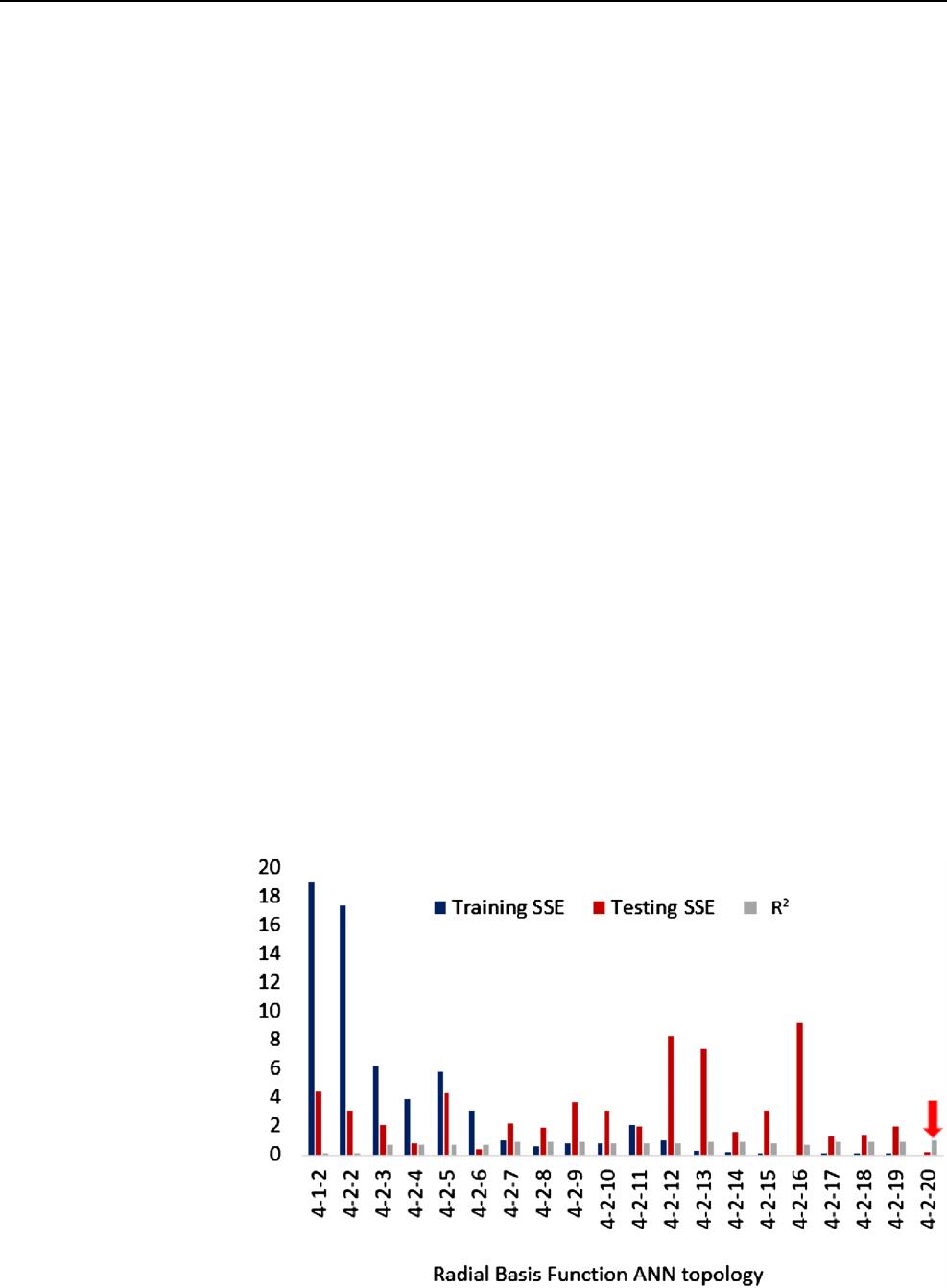

3.2 The Radial Basis Function ANN Model

Performance

3.2.1 Determination ofBest Model Architecture

Prior to the modeling of the thermo-catalytic CO

2

oxidative

coupling of methane, various Radial Basis Function ANN

configurations were tested to determine the model with the

best performance. The Radial Basis Function ANN was con-

figured by varying the hidden neurons from 1 to 20. Each of

the configurations was trained and tested to determine their

performance in terms of the SSE and R

2

. The SSE obtained

during the training and testing of each of the Radial Basis

Function ANN topology and the overall R

2

are depicted in

Fig.5. It can be seen that each of the Radial Basis Func-

tion ANN topologies has varying performance during train-

ing and testing. Since the network is adjusted based on the

weights associated with input and the hidden neurons, the

performance of each of the ANN topology will vary based

on the changes in the hidden neuron. The best performance

of the Radial Basis Function ANN models was obtained for

the 4-20-2 topology as indicated by the red arrow in Fig.5.

The 4-20-2 configurations imply the ANN model consists

of 4 input units, 20 hidden neurons, and 2 output units. The

training and testing of the 4-20-2 Radial Basis Function

ANN resulted in SSE of 3.9 × 10

−24

and 0.224, respectively,

and R

2

of 0.990. The use of 4-9-1 and 4-6-1 architecture for

Levenberg–Marquardt trained multilayer perceptron ANN

has been reported by Ehsani etal. [26]. The variation in the

network architectures could be attributed to the peculiarity

and the inbuilt algorithms of the Radial Basis Function ANN

and the Levenberg–Marquardt trained multilayer perceptron

ANN.

Fig. 5 SSE and R

2

values

obtained for training and testing

the various topology of the

Radial Basis Function ANN

Topics in Catalysis

1 3

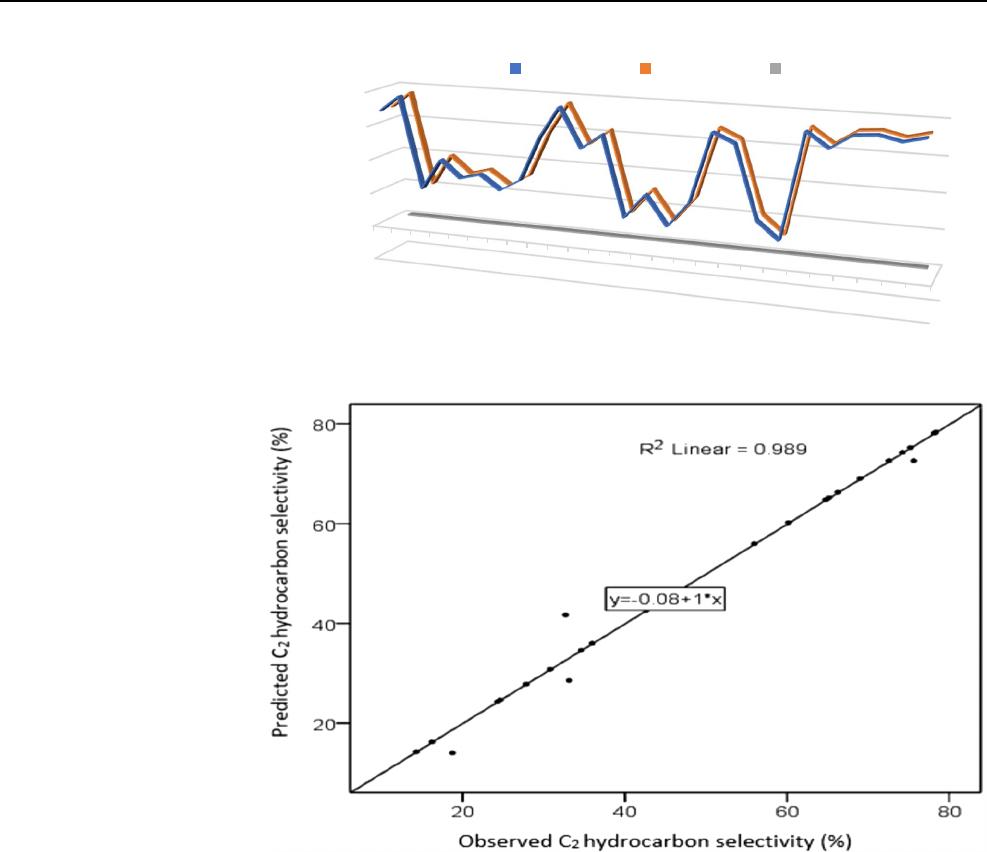

3.2.2 The Model Performance

The performance of the 4-20-2 configured Radial Basis

Function ANN in terms of predicting the C

2

selectivity and

yields are depicted in Figs.6 and 7, respectively. As shown

in Fig.6a, at every point of the experimental runs, the pre-

dicted C

2

selectivity is in proximity to the observed values

with all the residuals value less than 0.5%. This can further

be substantiated by the linear regression plots depicted in

Fig.6b. With R

2

of 0.989 and residual <0.05%, it is certain

that the Radial Basis Function ANN model is robust in gen-

eralizing 98.9% of the data which is comparable with that

reported in the literature. Huang etal. [27] reported a predic-

tive error of 0.162% for modeling a multi-component catalyst

used in methane oxidative coupling using Levenberg–Mar-

quardt-trained multilayer perceptron ANN. The predicted

C

2

selectivity by the Levenberg–Marquardt-trained multi-

layer perceptron was in close agreement with the observed

values. Also, in a similar study reported by Abdolahi etal.

[35] whereby a feed-forward Levenberg–Marquardt-trained

multilayer perceptron ANN was employed to model the pre-

diction of C

2

hydrocarbon selectivity, C

2

H

4

selectivity, and

CH

4

conversion, the predicted values were consistent with

the observed values with minimal errors. Several authors

have reported the superiority of the Radial Basis Function

ANN for predictive modeling compared to the multilayer

perceptron [36–38].

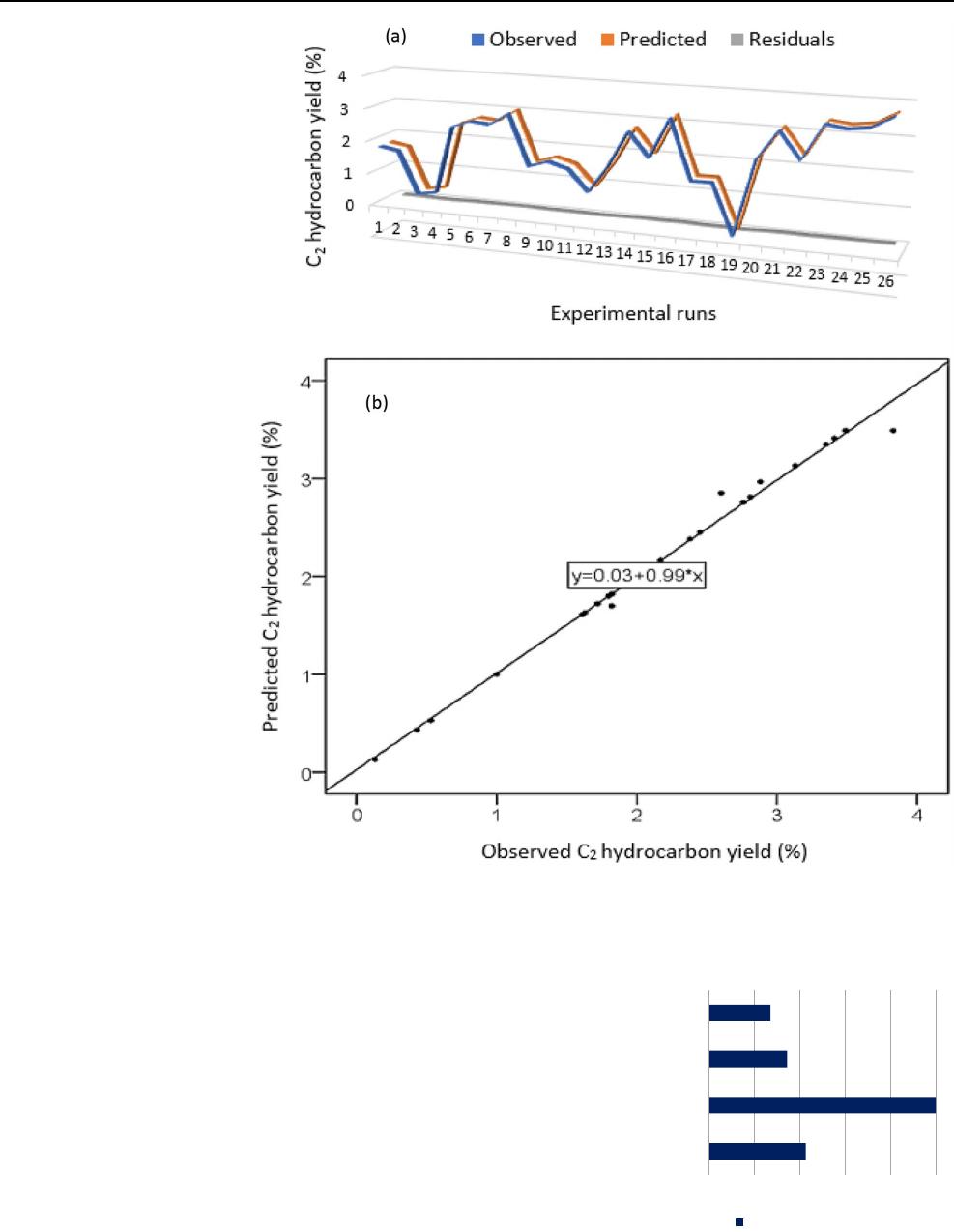

The Radial Basis Function ANN performance in terms

of the prediction of the C

2

hydrocarbon yield is depicted

in Fig.7. The Radial Basis Function ANN architecture

displayed a well-generalized prediction of C

2

hydrocarbon

yield as illustrated in Fig.7a. For all experimental runs,

the predicted C

2

hydrocarbon yields are consistent with the

observed values. This can further be ascertained from the

regression plot in Fig.7b. With an R

2

of 0.998 and residu-

als less than 0.05, 99.8% of the data can be explained and

Fig. 6 (a) Dispersion plot show-

ing the predicted, observed and

the residuals of C

2

hydrocarbon

selectivity (b) Regression plot

showing the predicted, observed

and the residuals of C

2

hydro-

carbon selectivity

-20

0

20

40

60

80

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

C

2

hydrocarbon selectivity (%)

Experimental runs

Observed Predicted Residuals

(a)

(b)

Topics in Catalysis

1 3

generalized by the Radial Basis Function ANN model. Fath

etal. [38] employed both Radial Basis Function ANN and

multilayer perceptron for modeling the prediction of solu-

tion gas-oil ratio of crude oil systems. The findings revealed

that the Radial Basis Function ANN model displayed a

higher accuracy in predicting the solution gas-oil ratio of

the crude oil systems. The robustness of the Radial Basis

Function ANN compared to multilayer perceptron ANN can

be attributed to its unique feature as a universal approxima-

tor whereby it has a high tendency to generalize any non-

linear process. The stability of the network system is often

enhanced due to its strong tolerance to input noise. Moreo-

ver, the simple nature of the three-layer architecture makes

the Radial Basis Function ANN easier to configure and train.

The sensitivity analysis as a function of the normalized

level of importance of the input parameters (temperature,

Fig. 7 (a) Dispersion plot show-

ing the predicted, observed and

the residuals of C

2

hydrocarbon

yield (b) Regression plot show-

ing the predicted, observed and

the residuals of C

2

hydrocarbon

yield

02040608

01

00

CO2/CH4 ratio

Temperature (oC)

Normalized Importance

Amount of MnO in catalyst (%)

Amount of CaO in catalyst (%)

Temperature (

o

C)

CO

2

/CH

4

ratio

Fig. 8 Sensitivity analysis showing the normalized importance of the

input parameters on the Radial Basis Function ANN model output

Topics in Catalysis

1 3

amount of CaO in the catalyst, amount of MnO in the cata-

lyst, and the CH

4

/CO

2

ratio) on the Radial Basis Function

ANN model outputs (C

2

hydrocarbon selectivity and yields)

is depicted in Fig.8. It can be seen that the four input param-

eters significantly influenced the predicted C

2

hydrocarbon

selectivity and yields. The normalized level of importance

revealed that the reaction temperature for the oxidative cou-

pling of methane has the most significant influence on the

C

2

hydrocarbon selectivity and yields. Based on the Arrhe-

nius concept, the gas-phase reaction is highly temperature

dependent [39]. The selectivity and yields of products

obtained from a gaseous phase reaction tend to increase with

an increase in temperature. However, increasing the tem-

perature beyond the thermodynamic acceptable limit could

have a negative effect on the catalytic performance. Hence,

a temperature control system could be incorporated into the

reactor design for the CO

2

oxidative coupling of methane. In

addition to the reaction temperature, the reactant (CO

2

/CH

4

)

ratio also has a significant influence on the C

2

hydrocarbon

selectivity and yields. As stated earlier, the C

2

hydrocarbon

selectivity and yields increased with an increase in CO

2

/CH

4

ratio and peaked at a CO

2

/CH

4

ratio of 2. A further increase

in the CO

2

/CH

4

ratio resulted in a corresponding decline in

the C

2

hydrocarbon selectivity and yields. This phenomenon

could be explained in terms of the occurrence of parallel

reactions such as CO

2

disproportion reaction and methane

cracking resulting in the deactivating of the catalysts by car-

bon deposition.

4 Conclusion

The modeling of thermo-catalytic CO

2

oxidative coupling

of methane for prediction of C

2

-hydrocarbon using Radial

Basis Function ANN has been investigated. Using the non-

linear relationship between the input parameters and the

process outputs, the performance of several configurations

of Radial Basis Function ANN models were examined. The

analysis of each of the Radial Basis Function ANN shows

that the model performance in terms of the prediction of the

C

2

hydrocarbon selectivity and yield are strongly dependent

on the number of hidden neurons. The Radial Basis Func-

tion ANN configuration with 20 hidden artificial neurons

displayed the best performance, evidenced from a very low

predictive error and high R

2

values of 0.998. The predicted

C

2

hydrocarbon selectivity and yields by the 4-20-2 Radial

Basis Function ANN architecture was in close agreement

with the observed values. This was further validated by a

strong correlation between the predicted and the observed

values as indicated by the R

2

of 0.989 and 0.998 for the C

2

selectivity and yields, respectively. Based on the sensitiv-

ity analysis, all the input parameters significantly influence

the prediction of C

2

selectivity and yields by the optimized

Radial Basis Function ANN. However, the reaction tem-

perature with the highest level of importance displayed the

most significant influence on the model output. The Radial

Basis Function ANN algorithm could be employed in incor-

porating a control system over the process variables when

considering the design of an optimized process for CO

2

oxi-

dative coupling of methane. Moreover, the outcome of the

sensitivity analysis can be incorporated as basis to designing

a robust catalyst for CO

2

oxidative coupling of methane.

References

1. Bakonyi P, Peter J, Koter S etal (2020) Possibilities for the bio-

logically-assisted utilization of CO

2

-rich gaseous waste streams

generated during membrane technological separation of bio-

hydrogen. J CO2 Util 36:231–243. https ://doi.org/10.1016/j.

jcou.2019.11.008

2. Yaashikaa PR, Senthil Kumar P, Varjani SJ, Saravanan A (2019)

A review on photochemical, biochemical and electrochemical

transformation of CO

2

into value-added products. J CO2 Util

33:131–147. https ://doi.org/10.1016/j.jcou.2019.05.017

3. Parvez AM, Afzal MT, Victor Hebb TG, Schmid M (2020) Uti-

lization of CO

2

in thermochemical conversion of biomass for

enhanced product properties: a review. J CO2 Util 40:101217.

https ://doi.org/10.1016/j.jcou.2020.10121 7

4. Ayodele BV, Khan MR, Cheng CK (2017) Greenhouse gases

mitigation by CO

2

reforming of methane to hydrogen-rich syn-

gas using praseodymium oxide supported cobalt catalyst. Clean

Techn Environ Policy 19:795–807. https ://doi.org/10.1007/s1009

8-016-1267-z

5. Skytt T, Nielsen SN, Jonsson B-G (2020) Global warming poten-

tial and absolute global temperature change potential from carbon

dioxide and methane fluxes as indicators of regional sustainability

– a case study of Jämtland, Sweden. Ecol Indic 110:105831. https

://doi.org/10.1016/j.ecoli nd.2019.10583 1

6. Khan AA, Tahir M (2019) Recent advancements in engineering

approach towards design of photo-reactors for selective photocata-

lytic CO

2

reduction to renewable fuels. J CO2 Util 29:205–239.

https ://doi.org/10.1016/j.jcou.2018.12.008

7. Din IU, Shaharun MS, Alotaibi MA etal (2019) Recent develop-

ments on heterogeneous catalytic CO

2

reduction to methanol. J

CO2 Util 34:20–33. https ://doi.org/10.1016/j.jcou.2019.05.036

8. Zhang Z, Zhang L, Hülsey MJ, Yan N (2019) Zirconia phase effect

in Pd/ZrO

2

catalyzed CO

2

hydrogenation into formate. Mol Catal

475:110461. https ://doi.org/10.1016/j.mcat.2019.11046 1

9. Ye R-P, Li Q, Gong W, Wang T, Razink JJ, Lin L, Qin YY, Zhou

Z, Adidharma H, Tang J, Russell AG (2020) High-performance

of nanostructured Ni/CeO

2

catalyst on CO

2

methanation. Appl

Catal B Environ 268:118474. https ://doi.org/10.1016/j.apcat

b.2019.11847 4

10. Wang Z, Cao XM, Zhu J, Hu P (2014) Activity and coke forma-

tion of nickel and nickel carbide in dry reforming: a deactivation

scheme from density functional theory. J Catal 311:469–480. https

://doi.org/10.1016/j.jcat.2013.12.015

11. Shin SA, Noh YS, Hong GH, Park JI, Song HT, Lee KY, Moon DJ

(2018) Dry reforming of methane over Ni/ZrO

2

-Al

2

O

3

catalysts:

effect of preparation methods. J Taiwan Inst Chem Eng 90:25–32.

https ://doi.org/10.1016/j.jtice .2017.11.032

12. Ayodele BV, Khan MR, Cheng CK (2015) Syngas production

from CO

2

reforming of methane over ceria supported cobalt

catalyst: effects of reactants partial pressure. J Nat Gas Sci Eng

27:1016–1023. https ://doi.org/10.1016/j.jngse .2015.09.049

Topics in Catalysis

1 3

13. Ayodele BV, Khan MR, Lam SS, Cheng CK (2016) Production

of CO-rich hydrogen from methane dry reforming over lanthania-

supported cobalt catalyst: kinetic and mechanistic studies. Int J

Hydrog Energy 41:4603–4615. https ://doi.org/10.1016/j.ijhyd

ene.2016.01.091

14. Mesrar F, Kacimi M, Liotta LF, Puleo F, Ziyad M (2018) Syn-

gas production from dry reforming of methane over ni/per-

lite catalysts: effect of zirconia and ceria impregnation. Int J

Hydrog Energy 43:17142–17155. https ://doi.org/10.1016/j.ijhyd

ene.2018.07.104

15. Li N, Li Y, Jiang R, Zhou J, Liu M (2019) Photocatalytic coupling

of methane and CO

2

into C

2

-hydrocarbons over Zn doped g-C

3

N

4

catalysts. Appl Surf Sci 498:143861. https ://doi.org/10.1016/j.

apsus c.2019.14386 1

16. Ma Y, Harding JD, Tu X (2019) Catalyst-free low tempera-

ture conversion of n-dodecane for co-generation of CO

x

−

free

hydrogen and C

2

hydrocarbons using a gliding arc plasma. Int J

Hydrog Energy 44:26158–26168. https ://doi.org/10.1016/j.ijhyd

ene.2019.08.067

17. Sundaram KM, Shreehan MM, Olszewski EF (2001) Ethylene.

In: Kirk-Othmer encyclopedia of chemical technology. American

Cancer Society

18. Istadi I, Amin NAS (2006) Optimization of process parameters

and catalyst compositions in carbon dioxide oxidative coupling

of methane over CaO-MnO/CeO

2

catalyst using response sur-

face methodology. Fuel Process Technol 87:449–459. https ://doi.

org/10.1016/j.fupro c.2005.11.004

19. Istadi I, Amin NAS (2006) Hybrid artificial neural network—

genetic algorithm technique for modeling and optimization of

plasma reactor hybrid artificial neural network—genetic algorithm

technique for modeling and optimization of plasma reactor. Ind

Eng Chem Res 45:6655–6664. https ://doi.or g/10.1021/ie060 562c

20. Koschwitz D, Frisch J, van Treeck C (2018) Data-driven heating

and cooling load predictions for non-residential buildings based

on support vector machine regression and NARX recurrent neural

network: a comparative study on district scale. Energy 165:134–

142. https ://doi.org/10.1016/j.energ y.2018.09.068

21. Alsaffar MA, Ayodele BV, Mustapa SI (2019) Scavenging carbon

deposition on alumina supported cobalt catalyst during renewable

hydrogen-rich syngas production by methane dry reforming using

artificial intelligence modeling technique. J Clean Prod 119168.

https ://doi.org/10.1016/j.jclep ro.2019.11916 8

22. Ayodele BV, Alsaffar MA, Mustapa SI, Vo DN (2020) Back-prop-

agation neural networks modeling of photocatalytic degradation

of organic pollutants using TiO

2

-based photocatalysts. J Chem

Technol Biotechnol 95(10):2739–2749. https ://doi.org/10.1002/

jctb.6407

23. Al-Haiqi O, Nour AH, Ayodele BV, Bargaa R (2020) Bayes-

ian regularization-trained multi-layer perceptron neural net-

work predictive modelling of phenol degradation using ZnO/

Fe

2

O

3

photocatalyst. J Phys Conf Ser 1529:052058. https ://doi.

org/10.1088/1742-6596/1529/5/05205 8

24. Li H, Zhang Z, Liu Z (2017) Application of artificial neural

networks for catalysis: a review. Catalysts 7:306. https ://doi.

org/10.3390/catal 71003 06

25. Ehsani MR, Bateni H, Razi Parchikolaei G (2013) Modeling

of oxidative coupling of methane over Mn/Na

2

Wo

4

/SiO

2

cata-

lyst using artificial neural network. Iran J Chem Chem Eng

32:107–114

26. Ehsani MR, Bateni H, Parchikolaei GR (2012) Modeling the oxi-

dative coupling of methane using artificial neural network and

optimizing of its operational conditions using genetic algorithm.

Korean J Chem Eng 29:855–861. https ://doi.org/10.1007/s1181

4-011-0250-y

27. Huang K, Zhan XL, Chen FQ, Lü DW (2003) Catalyst design for

methane oxidative coupling by using artificial neural network and

hybrid genetic algorithm. Chem Eng Sci 58:81–87. https ://doi.

org/10.1016/S0009 -2509(02)00432 -3

28. Istadi I, Amin NAS (2006) Hybrid artificial neural network-

genetic algorithm technique for modeling and optimization of

plasma reactor. Ind Eng Chem Res 45:6655–6664. https ://doi.

org/10.1021/ie060 562c

29. Hossain MA, Ayodele BV, Cheng CK, Khan MR (2016) Artifi-

cial neural network modeling of hydrogen-rich syngas production

from methane dry reforming over novel Ni/CaFe

2

O

4

catalysts. Int

J Hydrog Energy 41:11119–11130. https ://doi.or g/10.1016/j.ijhyd

ene.2016.04.034

30. Hossain MS, Ong ZC, Ismail Z, Khoo SY (2017) A comparative

study of vibrational response based impact force localization and

quantification using radial basis function network and multilayer

perceptron. Expert Syst Appl 85:87–98. https ://doi.org/10.1016/j.

eswa.2017.05.027

31. Garson GD (1991) Comparison of neural network analysis of

social science data. Soc Sci Comput Rev 9:399–434

32. Sunphorka S, Chalermsinsuwan B, Piumsomboon P (2017) Appli-

cation of artificial neural network for kinetic parameters predic-

tion of biomass oxidation from biomass properties. J Energy Inst

90:51–61. https ://doi.org/10.1016/j.joei.2015.10.007

33. Chen D, Lødeng R, Anundskås A etal (2001) Deactivation

during carbon dioxide reforming of methane over Ni catalyst:

microkinetic analysis. Chem Eng Sci 56:1371–1379. https ://doi.

org/10.1016/S0009 -2509(00)00360 -2

34. Ginsburg JM, Piña J, El Solh T, De Lasa HI (2005) Coke forma-

tion over a nickel catalyst under methane dry reforming condi-

tions: thermodynamic and kinetic models. Ind Eng Chem Res

44:4846–4854. https ://doi.org/10.1021/ie049 6333

35. Abdolahi F, Mortazavi Y, Khodadadi A etal (2005) Modeling of

methane oxidative coupling under periodic operation by neural

network. Chem Eng Technol 28:581–586. https ://doi.org/10.1002/

ceat.20040 7041

36. Han H-G, Qiao J-F, Chen Q-L (2012) Model predictive control

of dissolved oxygen concentration based on a self-organizing

RBF neural network. Control Eng Pract 20:465–476. https ://doi.

org/10.1016/j.conen gprac .2012.01.001

37. Alsaffar MA, Ayodele BV, Mustapa SI (2020) Scavenging carbon

deposition on alumina supported cobalt catalyst during renew-

able hydrogen-rich syngas production by methane dry reform-

ing using artificial intelligence modeling technique. J Clean Prod

247:119168. https ://doi.org/10.1016/j.jclep ro.2019.11916 8

38. Hashemi Fath A, Madanifar F, Abbasi M (2020) Implementa-

tion of multilayer perceptron (MLP) and radial basis function

(RBF) neural networks to predict solution gas-oil ratio of crude

oil systems. Petroleum 6:80–91. https ://doi.org/10.1016/j.petlm

.2018.12.002

39. Crowley JN, CampuzanoJost P, Moortgat GK (1996) Temperature

dependent rate constants for the gas-phase reaction between OH

and CH

3

OCl. J Phys Chem 100:3601–3606

Publisher’s Note Springer Nature remains neutral with regard to

jurisdictional claims in published maps and institutional affiliations.