http://journals.cambridge.org Downloaded: 11 Mar 2015 IP address: 203.64.11.45

Microstructure and misfit relaxation in SrTiO

3

/SrRuO

3

bilayer films on LaAlO

3

(100) substrates

J.S. Wu,

a)

C.L. Jia, and K. Urban

Institut fu¨r Festko¨rperforschung, Forschungszentrum Ju¨lich GmbH, D-52425 Ju¨lich, Germany

J.H. Hao and X.X. Xi

Department of Physics, The Pennsylvania State University, University Park, Pennsylvania 16802

(Received 12 March 2001; accepted 12 September 2001)

We studied the microstructure of SrTiO

3

/SrRuO

3

bilayer films on (001) LaAlO

3

substrates by high-resolution transmission electron microscopy. At the SrRuO

3

/LaAlO

3

interface a defect configuration of stacking faults and nanotwins bounding either Frank

partial dislocations or Shockley partial dislocations and complex interaction between

these planar defects were found to be the dominant means of misfit accommodation.

The misfit in the SrTiO

3

/SrRuO

3

system, however, is mainly accommodated by

elastic strain. Most of the observed defects in the SrTiO

3

layer can be related to the

{111} planar defects in the SrRuO

3

layer propagating and reaching the SrTiO

3

/SrRuO

3

interface. Furthermore, a {110} planar defect can also be introduced in the SrTiO

3

layer due to the structure change of the SrTiO

3

/SrRuO

3

interface.

I. INTRODUCTION

The deposition of high-quality perovskite ceramic thin

films for various applications is one of the most active

areas in materials research. SrRuO

3

has attracted consid-

erable interest in recent years due to its good conductiv-

ity, high chemical and thermal stability, and excellent

lattice match with many other electroceramic materials

such as SrTiO

3

and YBa

2

Cu

3

O

7

.

1–6

In superconducting

devices, SrRuO

3

films have been used as buffer layers

for the growth of high-temperature superconducting

YBa

2

Cu

3

O

7−x

films and also as a barrier layer in Joseph-

son junctions.

3,4

In ferroelectric nonvolatile memory ap-

plications, they have been employed as electrodes.

5,6

The

microstructure and defects in the SrRuO

3

layer are im-

portant since they can have a considerable effect on the

device layers which directly connect to the SrRuO

3

layer.

It is known that SrTiO

3

is an interesting dielectric

material and suitable for various applications such as

voltage tunable filters, oscillators, and phase shifters for

microwave circuits.

8,9

However, the properties of SrTiO

3

thin films which are necessary for device applications are

not as good as those of bulk single crystals. Their tun-

ability is lower and the dielectric losses are high.

10,11

Recently, with employment of SrRuO

3

as the buffer

layer, high-quality SrTiO

3

films with near single-crystal

level dielectric loss were successfully prepared on

LaAlO

3

substrates.

12

Besides perfect dislocations, partial

dislocations including both Shockley-type with Burgers

vectors inclined to the interfaces and Frank-type in the

interfaces were proposed as effective means of misfit

relaxation in the heterostructure system.

13

The dissocia-

tion of 60° dislocations in epitaxial semiconductor films

and the role of the resulting partials in misfit relaxation

have been well established. Partial dislocations of

a/2〈101〉 type accompanied by stacking faults in the

(010) plane have been observed in several perovskite

films.

14–17

At room temperature SrRuO

3

is a distorted perovskite

with orthorhombic lattice and has a pseudocubic lattice

parameter of 0.3928 nm. SrTiO

3

has perovskite cubic

structure with a ⳱ 0.3905 nm. The substrate, LaAlO

3

,is

a rhombohedrally distorted perovskite, and its pseudocubic

parameter is 0.3790 nm. On the basis of the lattice para-

meter values the lattice mismatch between SrRuO

3

and

LaAlO

3

is 3.6%, while that for the SrTiO

3

/SrRuO

3

sys-

tem is only 0.64%. In the following, the slight distortions

of SrRuO

3

and LaAlO

3

from cubic-perovskite are ne-

glected to simplify the discussion. The microstructure of

SrRuO

3

films on SrTiO

3

and LaAlO

3

substrates was

studied. While misfit dislocations and other defects could

be hardly found at the SrTiO

3

/SrRuO

3

interface,

18

a high

density of defects is observed in the SrRuO

3

/LaAlO

3

interfaces.

19

No perfect misfit dislocations were found at

the SrRuO

3

/LaAlO

3

interface, and the mechanism of

misfit relaxation at the SrRuO

3

/LaAlO

3

interface remains

unclear.

In this paper, we report on a high-resolution trans-

mission electron microscopy (HRTEM) study of

SrTiO

3

/SrRuO

3

bilayer films on (100) LaAlO

3

substrates.

a)

Present address: Department of Physics and Astronomy, Arizona

State University, Tempe, AZ 85287.

J. Mater. Res., Vol. 16, No. 12, Dec 2001 © 2001 Materials Research Society 3443

http://journals.cambridge.org Downloaded: 11 Mar 2015 IP address: 203.64.11.45

The emphasis is on the mechanisms of misfit relaxation

at the two interfaces. The defects generated in the SrTiO

3

device layer are also discussed.

II. EXPERIMENTAL

The SrTiO

3

/SrRuO

3

bilayer films were grown by

pulsed laser deposition on LaAlO

3

(100) single-crystal

substrates. A pulsed laser beam (wavelength: 248 nm)

was focused on ceramic SrRuO

3

or SrTiO

3

targets with

an energy density of 1.4 J/cm

2

. During deposition, the

substrate, about 7 cm away from the target, was heated

to 720 °C at an oxygen pressure of 100 mtorr. The

deposited films were then cooled to room temperature

at 400 torr of O

2

. Cross-sectional samples were prepared

by cutting films along the (100) and (110) planes

of LaAlO

3

. Two slices were glued face to face and

then embedded in epoxy resin. After the glue had been

cured, disks with a diameter of 3 mm were obtained

by cutting away redundant epoxy. These disks were

then ground, dimpled, and polished, followed by Ar

ion milling in a stage cooled with liquid nitrogen.

HRTEM investigations were carried out in a JEOL

4000EX electron microscope operated at 400 kV.

Image simulations were carried out using Mac-Tempas

software.

20

III. RESULTS AND DISCUSSION

A. Misfit relaxation in the

SrRuO

3

/LaAlO

3

interface

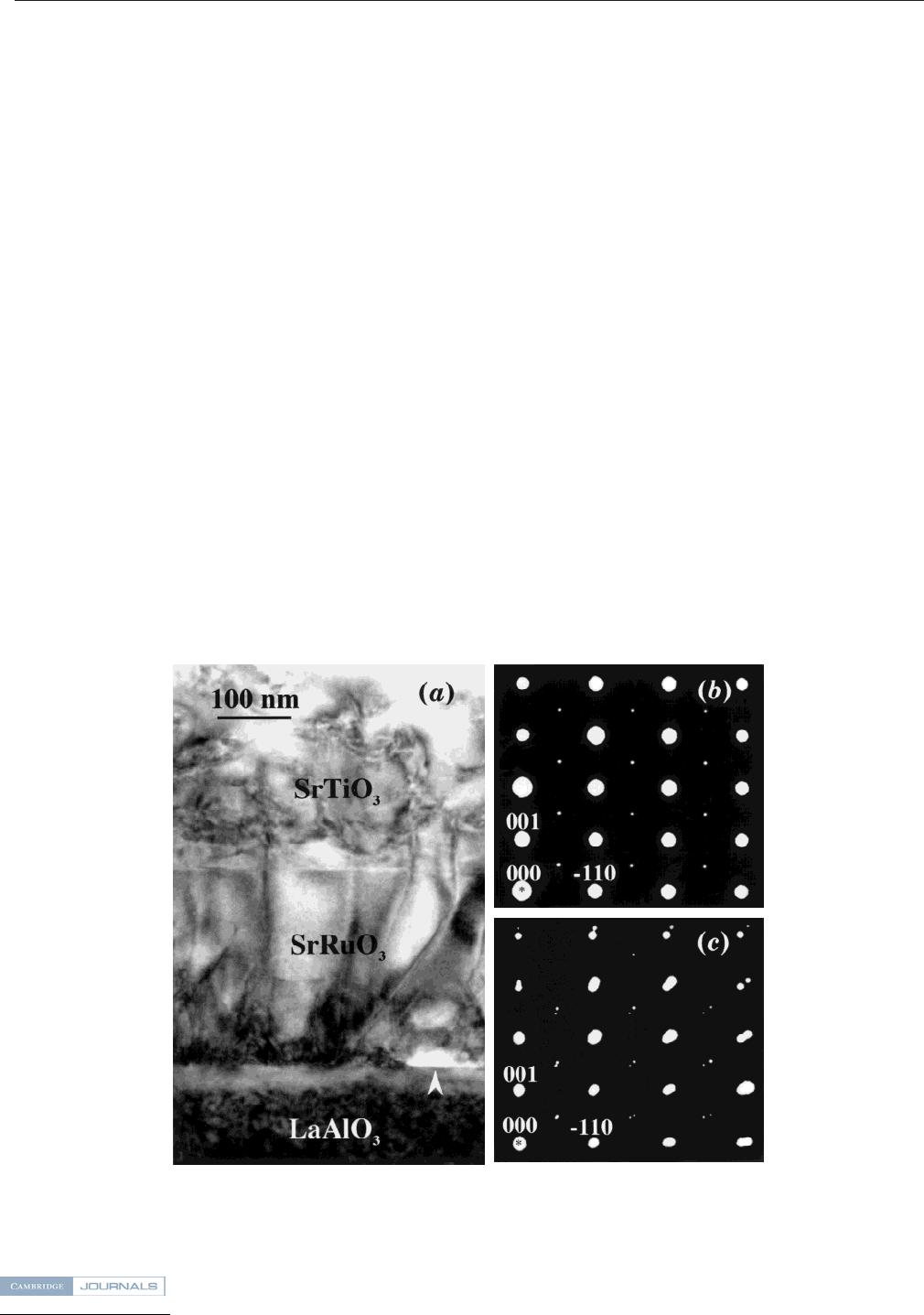

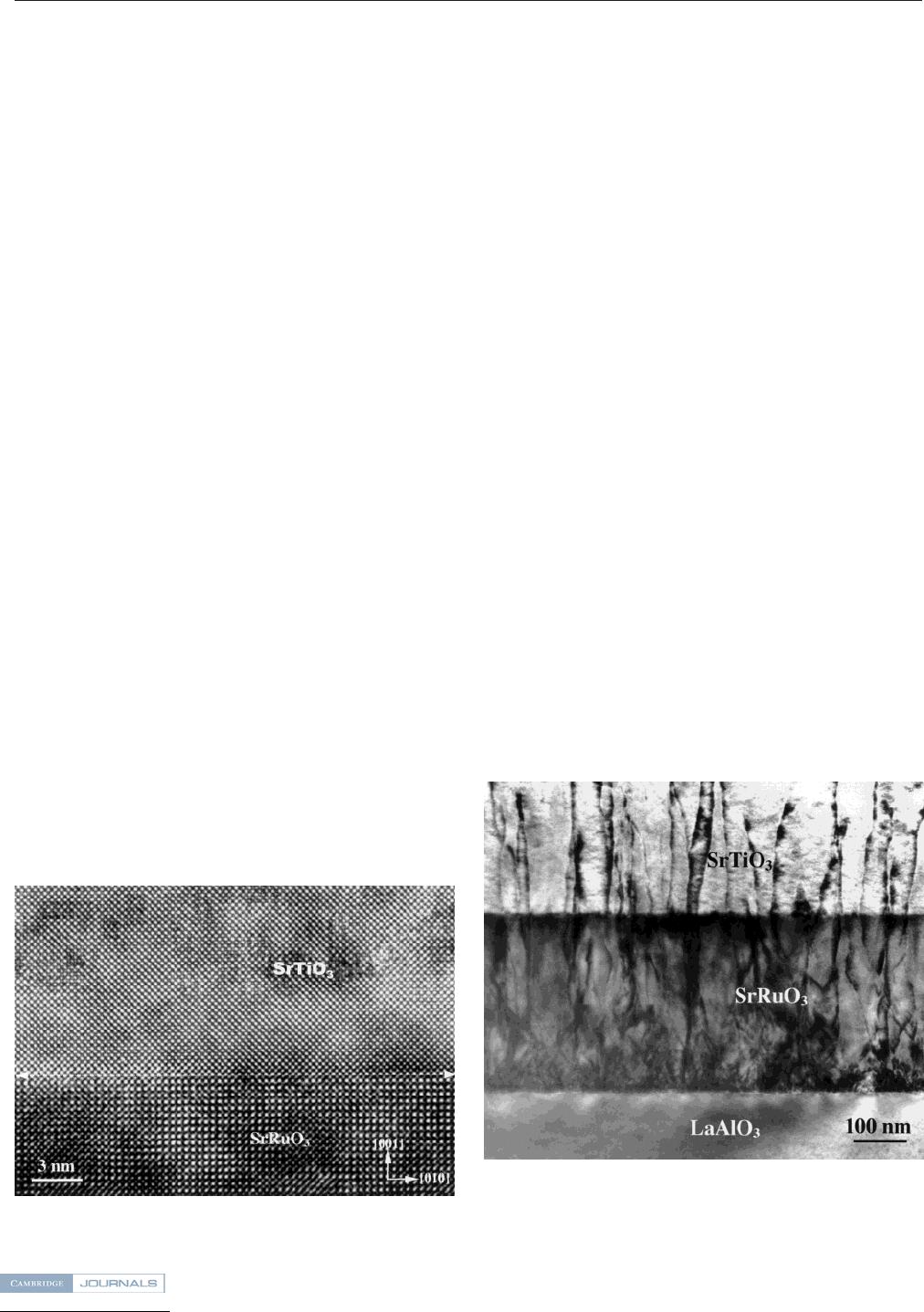

Figure 1(a) shows a low-magnification cross-sectional

image of a two-layer SrTiO

3

/SrRuO

3

film on LaAlO

3

taken along the [110] direction of the substrate. A high

density of defects can be observed along the SrRuO

3

/

LaAlO

3

interface. Some of the defects extend a signifi-

cant distance into the SrTiO

3

layer. Figure 1(b) is a

quarter of an electron diffraction pattern (EDP) obtained

by centering the selected-area diffraction aperture on the

SrTiO

3

/SrRuO

3

interface area. Figure 1(c) is the corre-

sponding pattern from the SrRuO

3

/LaAlO

3

interface

area. With reference to the pseudocubic cells of SrRuO

3

and LaAlO

3

, a simple cubic-to-cubic orientation relation-

ship can be derived from the EDP. The EDP of the

SrRuO

3

/LaAlO

3

interface area [Fig. 1(c)] consists of two

sets of diffraction spots which can easily be distin-

guished. The splitting of the spots indicates that a mis-

match relaxation between the SrRuO

3

and LaAlO

3

lattices has occurred. However, no splitting of the spots

can be detected in the pattern of the SrTiO

3

/SrRuO

3

in-

terface area [Fig. 1(b)].

To obtain information on the fine structure of the

defects at the SrRuO

3

/LaAlO

3

interface, we investi-

gated this interface along both the [100] and the [110]

FIG. 1. (a) Cross-sectional HRTEM image at low magnification of a SrTiO

3

/SrRuO

3

bilayer film on the LaAlO

3

substrate along the [110]

direction. An arrowhead shows a small hole at the SrRuO

3

/LaAlO

3

interface. A quarter of a superposed electron diffraction pattern taken (b) from

the SrTiO

3

/SrRuO

3

interface area and (c) from the SrRuO

3

/LaAlO

3

interface area, respectively. The central spots are indicated by an asterisk,

and the (

¯

110) and (001) diffraction spots are labeled in (b) and (c) by employing a notation for a pseudocubic structure.

J.S. Wu

et al.:

Microstructure and misfit relaxation in SrTiO

3

/SrRuO

3

bilayer films on LaAlO

3

(100) substrates

J. Mater. Res., Vol. 16, No. 12, Dec 20013444

http://journals.cambridge.org Downloaded: 11 Mar 2015 IP address: 203.64.11.45

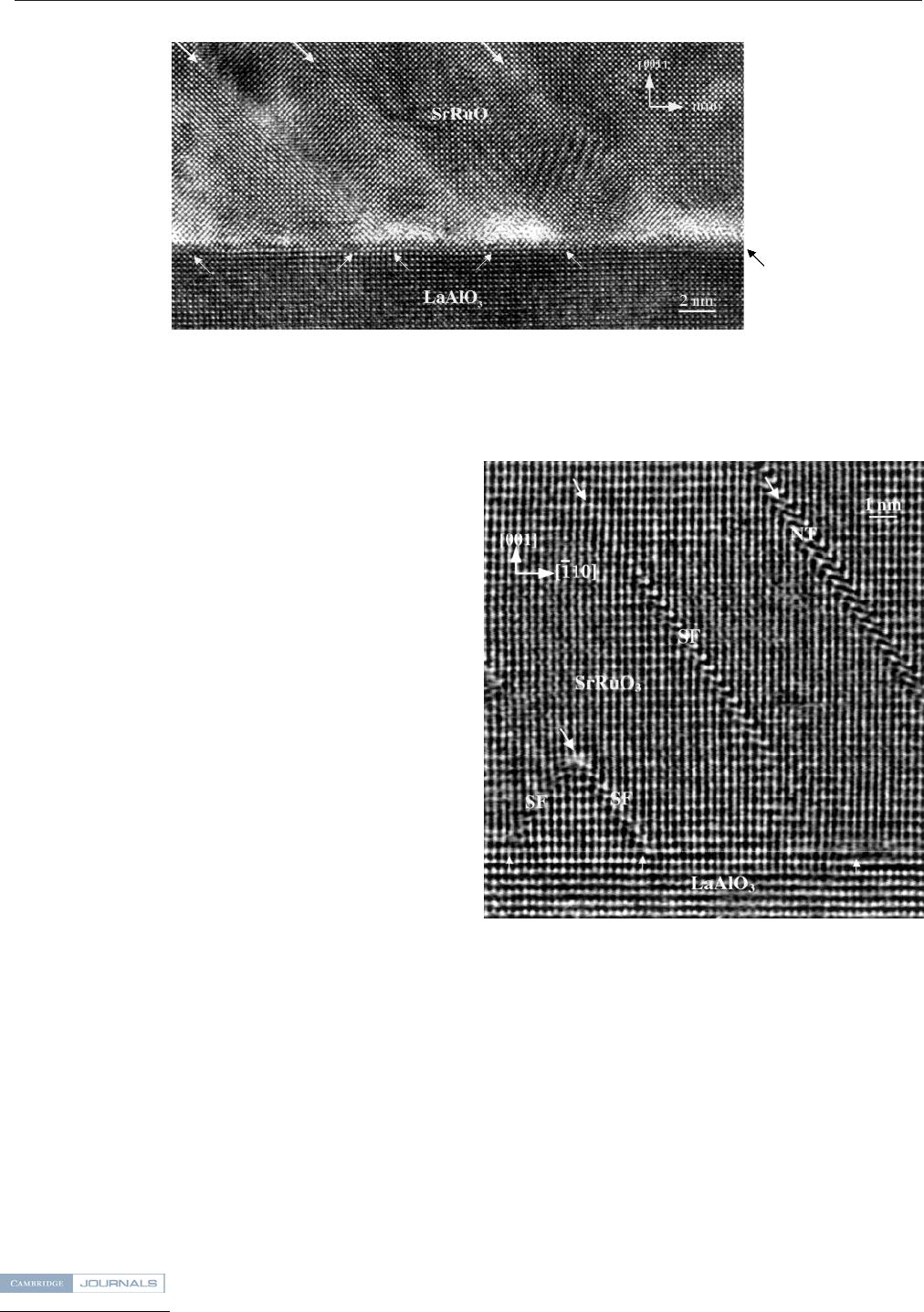

directions as shown in Figs. 2 and 3, respectively. If one

looks at the image in Fig. 2 along the 〈011〉 direction,

lattice planes in the LaAlO

3

substrate can be found to

terminate at the interface as indicated by small white

arrows. Associated with the termination of these lattice

planes, a change in image contrast appears in the SrRuO

3

layer both in the interface area and also farther away

from it, as shown by large white arrows. The change of

image contrast in Fig. 2 can be well understood by an

investigation of the interface area along the [110] direc-

tion as shown in Fig. 3. In this figure {111} planar de-

fects, stacking faults and nanotwins, can be seen as

indicated in the figure. Along the [110] direction, the

{111} defects are in edge on orientation so that they can

be identified easily. Every {111} planar defect is related

to one of the LaAlO

3

lattice planes terminating in the

interface as indicated by white arrows in the SrRuO

3

/

LaAlO

3

interface. In the left-hand part of Fig. 3, it is

interesting to note that the two stacking faults in the (1

¯

11)

and the (11

¯

1) plane, respectively, meet each other and are

pinned in the SrRuO

3

layer at about 4 nm above the

interface.

In the SrRuO

3

structure the stacking of atomic planes

along the 〈111〉 directions consists of alternating layers

of SrO

3

4−

and Ru

4+

.IfSrO

3

4−

layers are represented

by capital letters A, B, and C and the Ru

4+

layers by

lower-case letters a, b, and c, the stacking sequence in

the perfect crystal is AcBaCbAcBaCb. In studies of de-

fects in oxides, the stacking sequence of atomic planes

consisting of large ions can be used as a representation

to describe the defects in the crystals since small ions

are believed to move to their proper sites driven by

Coulomb force.

Nanotwins and stacking faults are two important

{111} planar defects in the perovskite structure. Two

basic types of faults, intrinsic and extrinsic, have to be

distinguished corresponding to the removal of a plane

from a perfect lattice or the insertion of an extra plane in

a perfect lattice, respectively. Such {111} faults can be

formed by propagation of partial dislocations. The glide

motion of Shockley partial dislocations with Burgers

vectors of the type 1/3〈112〉 can cause an intrinsic or an

extrinsic stacking fault in a BaTiO

3

crystal as described

by Eibl et al.

21

For example, the movement of a Shockley

partial dislocation transfers a {111} plane from the A to

FIG. 2. Cross-section HRTEM image of the interface between the SrRuO

3

layer and the LaAlO

3

substrate taken along the [100] direction, showing

a series of extra lattice planes terminating at the interface marked by small white arrows. The large white arrows denote a regular change of the

image contrast related to the termination of the extra planes.

FIG. 3. Cross-section HRTEM image of a SrRuO

3

/LaAlO

3

interface

taken along the [110] direction, showing three {111} stacking faults

(“SF”) and a nanotwin labeled “NT”. In the left part of the image, a

(1

¯

11) and a (11

¯

1) stacking fault terminate by their intersection.

J.S. Wu

et al.:

Microstructure and misfit relaxation in SrTiO

3

/SrRuO

3

bilayer films on LaAlO

3

(100) substrates

J. Mater. Res., Vol. 16, No. 12, Dec 2001 3445

http://journals.cambridge.org Downloaded: 11 Mar 2015 IP address: 203.64.11.45

B, B to C, and C to A position and thus changes the

stacking sequence from ABCABCAB to ABCBCABC

forming an intrinsic stacking fault. Stacking faults can

also form by the precipitation of point defects (vacancies

or interstitial atoms) in disk-shaped aggregates on the

{111} planes, i.e., by the climbing of Frank partial dis-

locations. It has been shown that {111} stacking faults

are formed by climb movement of a/3〈111〉 partial dis-

locations in BaTiO

3

thin films.

22

The formation of {111}

nanotwins can be understood as the result of stacking

faults extending in thickness.

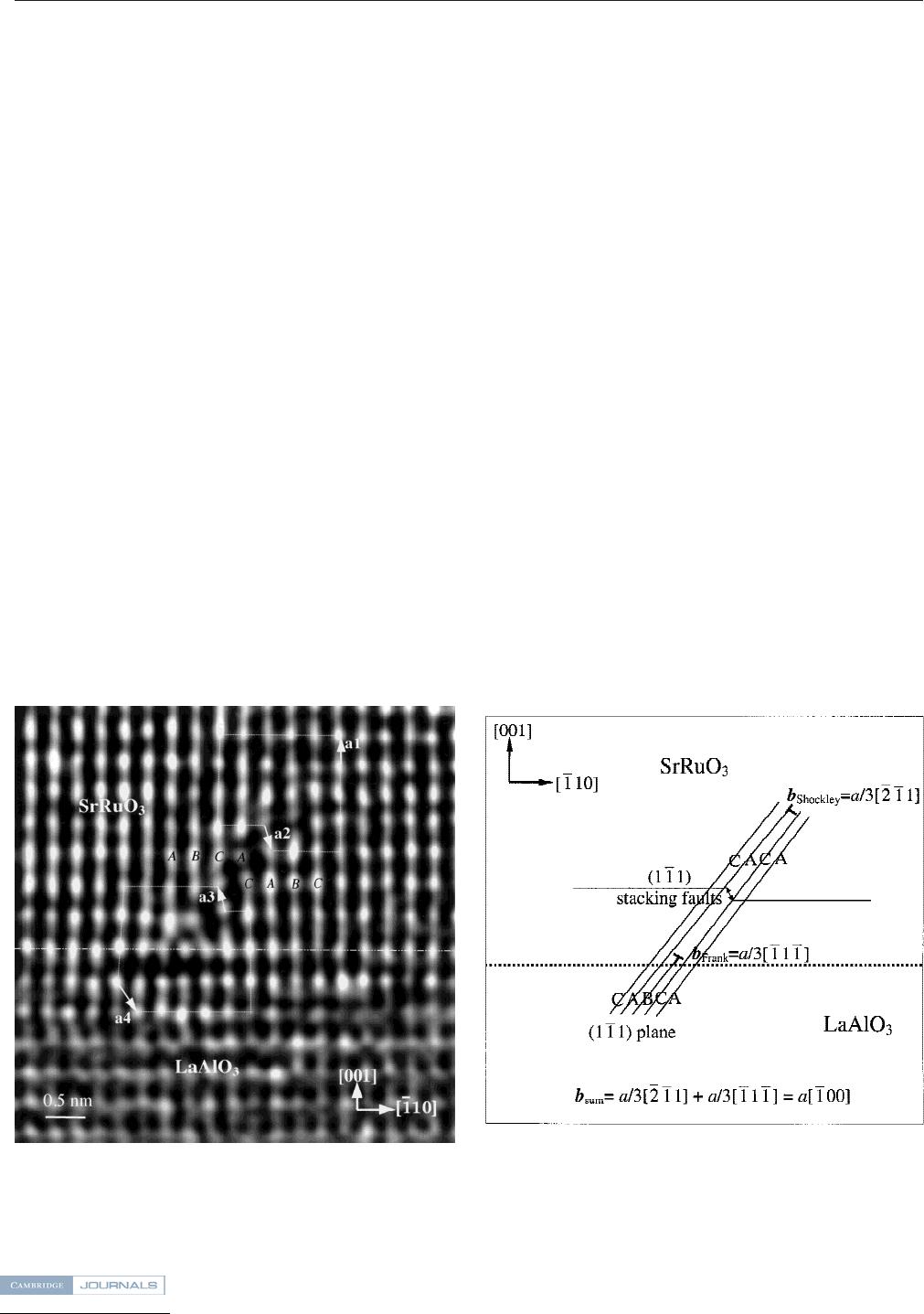

Figure 4 shows a stacking fault at the SrRuO

3

/LaAlO

3

interface. If the stacking notation introduced above is

employed, the stacking fault is identified as intrinsic type

with the ABCACABC sequence as indicated by the let-

ters. Burgers circuits are drawn to determine the dis-

placement vector at the ends of the stacking fault.

The projected displacement vector across the (11

¯

1)

stacking fault is a/6[1

¯

14

¯

] marked by the small white

arrow a2 (or a/6[11

¯

4] by arrow a3). At one end of the

stacking fault in the SrRuO

3

layer, the additional closure

failure is a[001] as indicated by the small white arrow a1.

The projected Burgers vector of the dislocation in the

SrRuO

3

layer thus can be determined as b

proj

⳱

a/6[1

¯

14

¯

]+a[001] ⳱ a/6[1

¯

12]. Unlike in the face-

centered cubic structure, a/6[1

¯

12] is not the Burgers

vector of the Shockley partial in the perovskite structure.

It is in fact the [110] projection of the Shockley partials

with the Burgers vector being either a/3[121] or

a/3[2

¯

1

¯

1]. At the other end in the substrate the additional

closure failure is a/2[1

¯

12

¯

] as indicated by the small white

arrow a4. With respect to the Burgers vector, the partial

dislocation at the end of the stacking fault at the inter-

face can therefore be characterized by b

proj

⳱ a/2[1

¯

12

¯

]+

a/6[11

¯

4] ⳱ a/3[1

¯

11

¯

]. This indicates a Frank partial dis-

location.

The geometrical configuration of the partials associ-

ated with the (11

¯

1) stacking fault in Fig. 4 is shown

in Fig. 5. The sum vector of the Shockley and the

Frank partial at both ends of the stacking fault is

b

sum

⳱ a[010] ⳱ a/3[1

¯

11

¯

]+a/3[121] or b

sum

⳱

a[1

¯

00] ⳱ a/3[1

¯

11

¯

]+a/3[2

¯

1

¯

1]. Therefore, the partials

and the accompanying stacking fault can be considered

as an extended dislocation dissociated from a perfect

dislocation with b ⳱ a〈100〉. Only one of the two pos-

sible cases is indicated in Fig. 5. Considering the value of

|b|

2

/a

2

as a measure for the dislocation energy, we obtain

1 ⳱ 3/9 + 6/9 before and after the reaction. Therefore,

the dissociation is not induced by self-energy but by

reduction of the strain energy in the interface area.

Obviously, the intrinsic stacking fault and its accom-

panying partial dislocation can contribute to the misfit

relaxation as that of perfect dislocation with Burgers

vector of a〈100〉. In fact, networks of the perfect mis-

fit dislocations with b ⳱ a〈100〉 have been observed

in perovskite films.

16,23

In this case, however, the

a〈100〉 type dislocation remains extended, like that in

the well-known system of a 30° partial and a 90° partial

FIG. 4. Image of a (11

¯

1) intrinsic stacking fault with stacking se-

quence ABCACABC at the SrRuO

3

/LaAlO

3

interface. Two Burgers

circuits are drawn to determine the Burgers vector of the dislocation

bounding the fault. The SrRuO

3

/LaAlO

3

interface is marked by a

dotted line.

FIG. 5. Geometric illustration of a partial dislocation pair bounding

the stacking fault in Fig. 4. The {111} planes are drawn as lines

and denoted by letters A, B, and C. The dotted line shows the

SrRuO

3

/LaAlO

3

interface, and the kink along the line parallel to [1

¯

10]

direction represents the intrinsic stacking fault. Two dislocations at the

ends of the stacking fault are indicated.

J.S. Wu

et al.:

Microstructure and misfit relaxation in SrTiO

3

/SrRuO

3

bilayer films on LaAlO

3

(100) substrates

J. Mater. Res., Vol. 16, No. 12, Dec 20013446

http://journals.cambridge.org Downloaded: 11 Mar 2015 IP address: 203.64.11.45

dissociated from a 60° misfit dislocation in the semi-

conducting films. The difference in the elastic moduli

of the LaAlO

3

crystal and the SrRuO

3

crystal can provide

the driving force for the dissociation of this dislocation

type. In this system the energy for maintaining a perfect

misfit dislocation in the interface can be higher than that

for two partials accompanying an intrinsic stacking fault.

Besides the {111} intrinsic stacking faults, extrinsic

stacking faults are also found in the SrRuO

3

/LaAlO

3

in-

terface. As shown in Fig. 6, an extrinsic stacking fault

can be identified referring to the stacking sequence of the

(1

¯

11) lattice planes which is ABCBABC as labeled. Em-

ploying a Burgers circuit consisting of two parts of clo-

sure failures as shown in the figure, we can identify the

dislocation at the end of the fault in the SrRuO

3

/LaAlO

3

interface. As shown by the arrows, a1 ⳱ a/3[11

¯

4

¯

]isthe

projected displacement vectors crossing the fault, while

a2 ⳱ a/2[1

¯

12

¯

] represents the additional closure failure.

The projected Burgers vector on the (110) plane of the

dislocation is thus b

proj

⳱ a/3[11

¯

4

¯

}+a/2[1

¯

12] ⳱

a/6[1

¯

12

¯

]. The Burgers vector of the dislocation can be

identified as either a/3[121

¯

]ora/3[2

¯

1

¯

1

¯

] as already dis-

cussed for Fig. 4.

The Shockley partial bounding the extrinsic stacking

fault in Fig. 6 at the SrRuO

3

/LaAlO

3

interface has edge

components of a/3〈120〉 in the interface plane, and the

extra lattice plane of the partial dislocation is on the side

of the LaAlO

3

substrate. Obviously, the extrinsic stack-

ing fault and its accompanying partial dislocation can

contribute to the misfit relaxation. Furthermore,

Wan et al.

24

showed that even for a null-type partial

dislocation dipole, which is formed by dissociation of a

screw threading dislocation, misfit strain could be re-

lieved, and the reduction of the misfit energy is propor-

tional to the width of the stacking fault.

In addition to the introduction of isolated {111} planar

defects, the interaction of the defects also plays an im-

portant role in misfit accommodation. As shown in the

left-hand part of Fig. 3, two {111} intrinsic stacking

faults meet and interact with each other. At the end of the

two stacking faults in the interface, two Frank partial

dislocations can be identified, while at the meeting points

a stair-rod dislocation occurs.

25

The sum of the Burgers

vector of these three partials is a〈100〉. This implies

that the contribution of the two intrinsic stacking faults to

the misfit relaxation is equivalent to that of a perfect

〈100〉 misfit dislocation. This can be concluded by

performing a large Burgers circuit around the two stack-

ing faults.

Figure 7 shows a special configuration of two {111}

stacking faults and a (001) planar defect. It is a super-

dislocation from the dissociation of a 〈110〉 type dislo-

cation according to our previous identification.

26

The (001) defect denoted by two white arrows is a

Ruddlesden–Popper planar defect while the two stacking

faults indicated by dotted lines are identified as intrinsic

{111} faults. If a large Burgers circuit is employed

around the whole area, a closure failure with a displace-

ment vector a〈110〉 is obtained as shown in Fig. 7. This

implies that the configuration of a (001) planar defect and

of the two stacking faults induces about the same con-

tribution to the misfit relaxation as that of a perfect 〈110〉

type misfit dislocation. This shows that the {111} planar

defects and their interaction play an important role in

misfit accommodation in the SrRuO

3

/LaAlO

3

interface.

FIG. 6. Image of a (1

¯

11) extrinsic stacking fault with stacking se-

quence ABCBABC at the SrRuO

3

/LaAlO

3

interface. A Burgers circuit

is drawn to determine the dislocation bounding the fault.

FIG. 7. Image of a SrRuO

3

/LaAlO

3

interface taken along the [110]

direction showing two {111} intrinsic stacking faults and a (001)

planar defect. Two arrows show the (001) planar defect, while the

kinks in two black lines show the stacking faults. The SrRuO

3

/LaAlO

3

interface is marked by a dotted line.

J.S. Wu

et al.:

Microstructure and misfit relaxation in SrTiO

3

/SrRuO

3

bilayer films on LaAlO

3

(100) substrates

J. Mater. Res., Vol. 16, No. 12, Dec 2001 3447

http://journals.cambridge.org Downloaded: 11 Mar 2015 IP address: 203.64.11.45

On the basis of statistics investigations, we find that

the distribution of the {111} stacking faults along the

interface is inhomogeneous. Besides the partials con-

nected to {111} stacking faults, the system also employs

other means to reduce misfit strain. In fact, we observe

amorphous patches at the interface. In Fig. 1 there is a

small hole in the SrRuO

3

/LaAlO

3

interface as indicated

by an arrowhead. This is caused by a faster ion-milling

rate in an amorphous patch during sample preparation.

B. Misfit relaxation in the

SrTiO

3

/SrRuO

3

interface

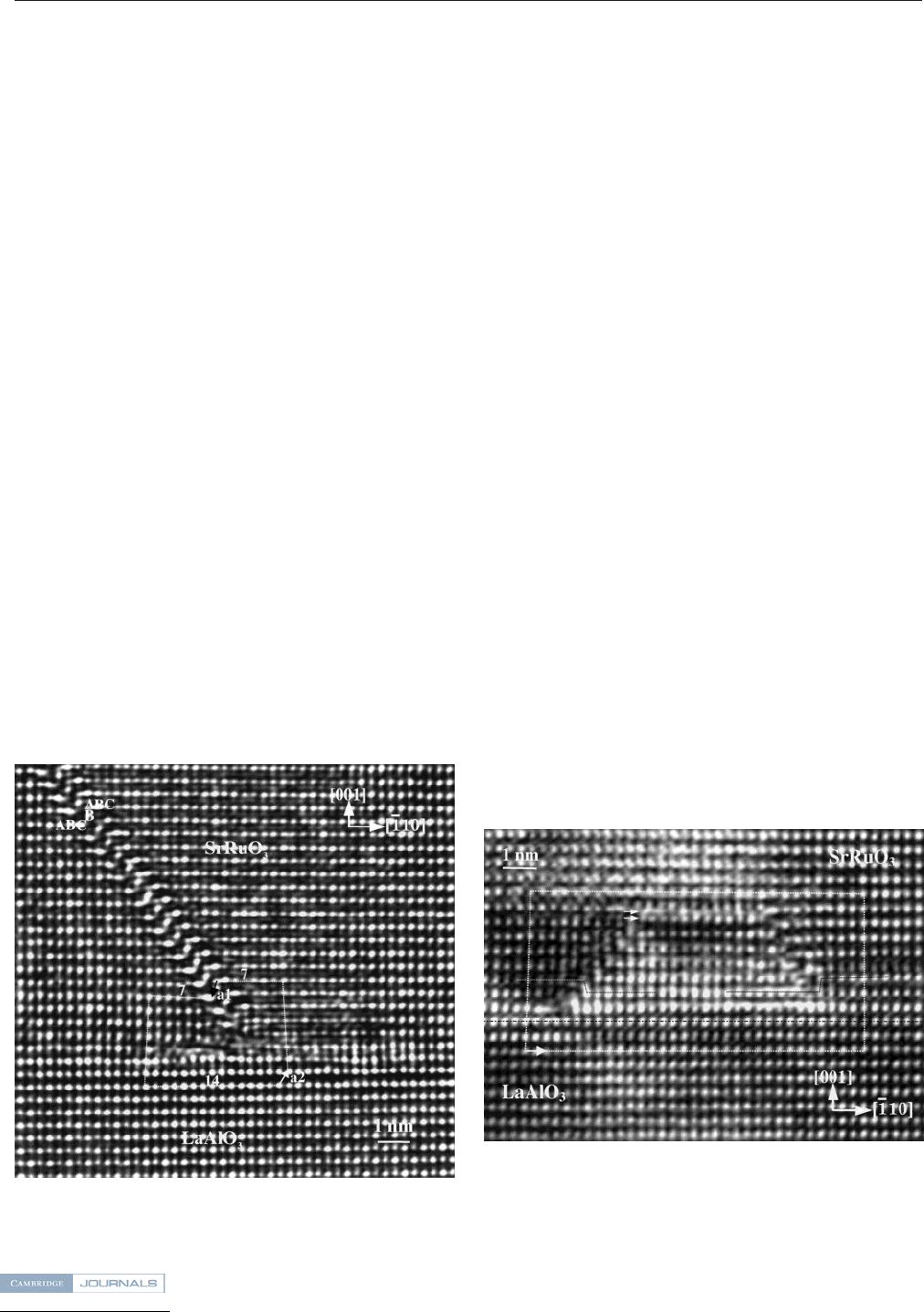

Figure 8 shows an HRTEM image of the SrTiO

3

/

SrRuO

3

interface along the [100] direction. The perfect

interface is free of misfit dislocations as shown by a

dotted white line. In HRTEM images we usually ob-

served a layer with a thickness of about 5 nm directly

above the interface which shows brighter contrast than

other areas in the SrTiO

3

layer. Detailed investigation for

fully understanding of the contrast origin of the layer is

underway. According to the perovskite unit cells at the

room temperature, the SrRuO

3

has a larger parameter. If

we use the SrRuO

3

as a reference, the (010) planes spac-

ing of the SrTiO

3

will become a little bit larger so that it

can fit the value. If the volume of unit cell is considered

unchanged, however, the SrTiO

3

(001) planes spacing

should be a little bit shorter than its bulk value. In other

words, since the SrTiO

3

layer is in a tensile strain in the

(001) interface plane, the (100) and (010) lattice spacing

of the SrTiO

3

layer becomes larger and the (001) spac-

ing smaller in comparison with the bulk lattice param-

eter. Meanwhile, the similar analysis of lattice distortion

in SrRuO

3

layer can also be drawn consistent with the

fact that it is in a compressive strain. Thus, although

the crystal structure of the SrTiO

3

crystal should be cubic

structure at the room temperature it in fact has a little

tetragonal distortion in the film layer influenced by the

tensile strain due to the lattice misfit between the lattices

of SrTiO

3

and SrRuO

3

.

C. Structural defects in the SrTiO

3

layer

Figure 9 is a cross-section diffraction contrast image

of the bilayer film taken along a direction about 10° away

from the [110] zone axis. Near the SrRuO

3

/LaAlO

3

in-

terface, defects with high density occur to relax the lat-

tice misfit between the SrRuO

3

and the LaAlO

3

. The

density of the planar defects in the upper part of

the SrRuO

3

layer is lower due to the barrier effect of the

dislocations formed by interaction of the defects.

27

In

the SrTiO

3

layer most of the defects are related to ex-

tending stacking faults in the SrRuO

3

layer. We also

observed a kind of {110} antiphase boundary in the

SrTiO

3

layer introduced by an extrinsic stacking fault

arriving at the SrTiO

3

/SrRuO

3

interface. Details have

been discussed elsewhere.

28

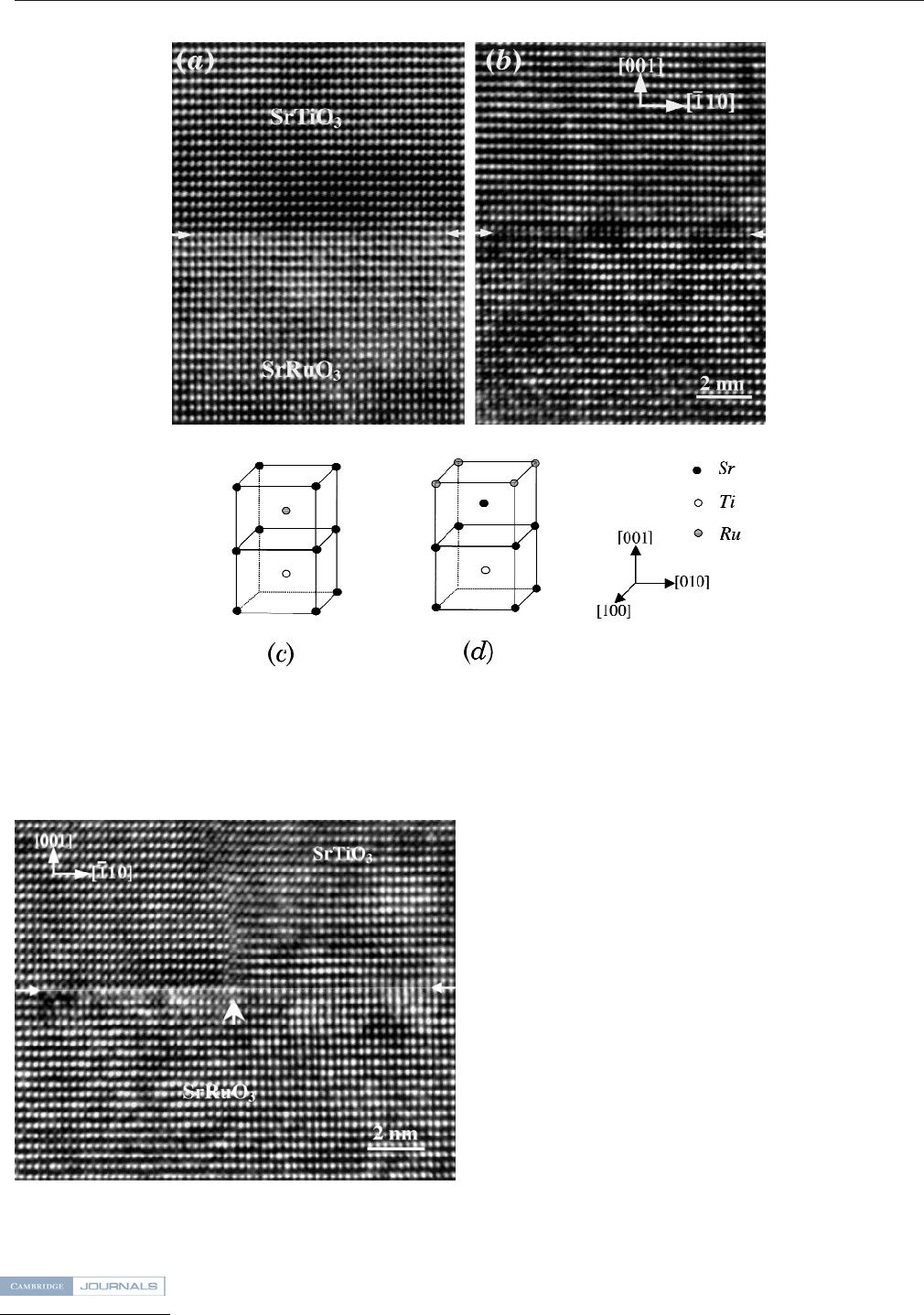

Figure 10 shows two cross-section HRTEM images of

the SrTiO

3

/SrRuO

3

interface taken along the [110] di-

rection. While the SrTiO

3

/SrRuO

3

interface in (a) looks

quasi-continuous from top to bottom, double spot con-

trast can be seen in the interface in (b). Across the inter-

face in (a) the normal stacking sequence of perovskite

structure is preserved, while the interface in (b) shows

the structure of a Ruddlesden–Popper planar defect, as

schematically illustrated in (c) and (d).

Figure 11 shows a {110} planar defect starting at the

point where the two different types of interface meet

(white vertical arrow). The orientation of the interface on

FIG. 8. Cross-section image of a SrTiO

3

/SrRuO

3

interface taken along

the [100] direction.

FIG. 9. Cross-section image taken along the direction which is about

10° away from the [110] zone axis. Most of the defects in the SrTiO

3

layer are introduced from the defect propagating through the SrRuO

3

layer and reaching the SrTiO

3

/SrRuO

3

interface.

J.S. Wu

et al.:

Microstructure and misfit relaxation in SrTiO

3

/SrRuO

3

bilayer films on LaAlO

3

(100) substrates

J. Mater. Res., Vol. 16, No. 12, Dec 20013448

http://journals.cambridge.org Downloaded: 11 Mar 2015 IP address: 203.64.11.45

the left-hand side is slightly inclined to the viewing di-

rection so that the contrast is a little blurred.

However, the pairs of spots in the interface can still be

recognized. The interface in the right-hand part of the

image, however, exhibits a single spot contrast across

the interface. The {110} planar defect (note the faint

contrast line parallel to the vertical arrow) in the SrTiO

3

layer is produced by the conjunction of the two segments

of the SrTiO

3

/SrRuO

3

interface with different structure.

IV. CONCLUSIONS

In a study of the microstructure of the SrTiO

3

/SrRuO

3

two-layer films on the (100) LaAlO

3

substrates, we

found that the misfit between the SrRuO

3

layer and the

LaAlO

3

substrate is mainly accommodated by partial dis-

locations accompanying {111} planar defects in the area

of the SrRuO

3

/LaAlO

3

interface. Some defects propagate

through the SrRuO

3

layer and reach the SrTiO

3

/SrRuO

3

interface giving rise to defects in the SrTiO

3

layer. The

FIG. 11. HRTEM image along the [100] direction of a conjunction of

two types of SrRuO

3

/LaAlO

3

interface structure. A {110} planar de-

fect is generated at the conjunction.

FIG. 10. HRTEM images along the [110] direction showing two different SrTiO

3

/SrRuO

3

interface structures (a) and (b). The interface structures

are illustrated in (c) and (d).

J.S. Wu

et al.:

Microstructure and misfit relaxation in SrTiO

3

/SrRuO

3

bilayer films on LaAlO

3

(100) substrates

J. Mater. Res., Vol. 16, No. 12, Dec 2001 3449

http://journals.cambridge.org Downloaded: 11 Mar 2015 IP address: 203.64.11.45

misfit between the SrTiO

3

and the SrRuO

3

layers is,

however, mainly accommodated by elastic strain. Differ-

ent types of interface structure are found. In particular,

{110} planar defects in the SrTiO

3

layer are generated at

the interface area where a change of interface struc-

ture occurs.

ACKNOWLEDGMENTS

J.S.Wu is grateful for support from the Alexander von

Humboldt-Stiftung. The work at Pennsylvania State was

partially supported by NSF under Grant No. DMR-

9702632 and by the DARPA FAME Program under Con-

tract No. DABT63-98-1-002.

REFERENCES

1. C.B. Eom, R.J. Cava, R.M. Fleming, J.M. Philips, R.B. van Dover,

J.H. Marshall, J.W.P. Hsu, J.J. Krajewski, and W.F. Peck, Jr.,

Science 258, 1766 (1993).

2. X.D. Wu, S.R. Foltyn, R.C. Dye, Y. Coulter, and R.E. Muenchausen,

Appl. Phys. Lett. 62, 2434 (1993).

3. L. Antognazza, K. Char, T.H. Geballe, L.L.H. King, and

A.W. Sleight, Appl. Phys. Lett. 63, 1005 (1993).

4. R. Domel, C.L. Jia, C. Competti, G. Ockenfuss, and A.I. Branginski,

Supercond. Sci. Technol. 7, 277 (1994).

5. C.B. Eom, R.B. Van Dover, Julia M. Philips, D.J. Marshall,

C.H. Chen, R.J. Cava, R.M. Fleming, and D.K. Fork, Appl. Phys.

Lett. 63, 2570 (1993).

6. Q.X. Jia, X.D. Wu, S.R. Foltyn, and P. Tiwari, Appl. Phys. Lett.

66, 2197 (1995).

7. R.C. Neville, B. Hoeneisen, and C.A. Mead, J. Appl. Phys. 43,

2124 (1972).

8. O.G. Vendik, L.T. Ter-Martirosyanm, A.I. Dedyk, S.F. Karmanenko,

and R.A. Chakalov, Ferroelectrics 144, 33 (1993).

9. F. Selmi, R. Hughes, V.K. Varadan, and V.V. Varadan, Proc.

SPIE 1916, 180 (1993).

10. A.T. Findikoglu, C. Dought, S.M. Anlage, Qi Li, X.X. Xi, and

T. Venkatesan, J. Appl. Phys. 76, 2937 (1994).

11. C.H. Mueller, R.E. Treece, T.V. Rivkin, F.A. Miranda,

H.R. Moutinho, A. Swartzlander-Franz, M. Dalberth, and

C.T. Rogers, IEEE Trans. Appl. Supercond. 7, 3512 (1997).

12. H.C. Li, W.D. Si, A.D. West, and X.X. Xi, Appl. Phys. Lett. 73,

190 (1998).

13. J.W. Matthews, in Dislocations in Solids, edited by F.R.N. Nabarro

(North-Holland, Amsterdam, The Netherlands, 1979), Chap. 7.

14. A.F. Marshall, K. Char, R.W. Barton, A. Kapitulnik, and

S.S. Laderman, J. Mater. Res. 5, 2049 (1990).

15. W. Pompe, X. Gong, Z. Suo, and J.S. Speak, J. Appl. Phys. 74,

6012 (1993).

16. S. Stemmer, S.K. Streiffer, F. Ernst, and M. Ru¨hle, Phys. Status

Solidi A 147, 135 (1995).

17. T. Suzuki, Y. Nishi, and M. Fujimoto, Philos. Mag. A 79, 2461

(1999).

18. J.C. Jiang, W. Tian, X.Q. Pan, Q. Gan, and C.B. Eom, Appl. Phys.

Lett. 72, 909 (1998).

19. P. Lu, F. Chu, Q.X. Jia, and T.E. Mitchell, J. Mater. Res. 13, 2302

(1998).

20. R. Kilaas, Proc. 45th Annual EMSA meeting, Baltimore, MD,

edited by G.W. Bailey (San Francisco Press, San Francisco, CA

1987), p. 66.

21. O. Eibl, P. Pongratz, and P. Skalicky, Philos. Mag. B 57, 521

(1988).

22. C.L. Jia, K. Urban, M. Mertin, S. Hoffmann, and A. Waser,

Philos. Mag. A 77, 923 (1998).

23. T. Suzuki, Y. Nishi, and M. Fujimoto, Philos. Mag. A 79, 2461

(1999).

24. X.Y. Wan, J.W. Liang, M.L. Liu, and X.L. Jin, Phys. Rev. B 55,

9259 (1997).

25. J.S. Wu, C.L. Jia, K. Urban, J.H. Hao, and X.X. Xi, Philos. Mag.

Lett. 81, 375 (2001).

26. J.S. Wu, C.L. Jia, K. Urban, J.H. Hao, and X.X. Xi, J. Cryst.

Growth, in press.

27. J.S. Wu, C.L. Jia, K. Urban, J.H. Hao, and X.X. Xi, Philos.

Mag. A (in press).

28. J.S. Wu, C.L. Jia, K. Urban, J.H. Hao, and X.X. Xi, J. Appl. Phys.

89, 5653 (2001).

J.S. Wu

et al.:

Microstructure and misfit relaxation in SrTiO

3

/SrRuO

3

bilayer films on LaAlO

3

(100) substrates

J. Mater. Res., Vol. 16, No. 12, Dec 20013450