ION

BEAM

INDUCED

GROWTH

STRUCTURE

OF

FLUORITE

TYPE

OXIDE

FILMS

FOR

BIAXIALLY

TEXTURED

HTSC

COATED

CONDUCTORS

Y.

IIJIMA,

M.

KIMURA, AND

T.

SAITOH

Fujikura

Ltd.,

1-5-1,

Kiba, Koto-ku,

Tokyo

135-8512,

JAPAN,

ABSTRACT

Biaxially

aligned

film

growth by dual-ion-beam

sputtering methods

were

studied

for

fluorite

type

(Zro.85Yo.15Oi.

93

(YSZ),

Hf

0

.

74

Yb

0

.

26

0

1

.

87

,

CeO

2

),

pyrochlore

type

(Zr

2

Sm

2

0

7

),

and

rare-earth

C

type

(Y

2

0

3

,

Sm

2

0

3

)

oxides

on

polycrystalline

Ni-based

alloy

substrates.

Cube-

textured

(all

axes

aligned

with

a

<100>

axis

substrate normal) films were

obtained for

fluorite

and

pyrochlore

ones

by

low

energy

(<300

eV)

ion bombardment

at

low

temperatures

(<

300

°C).

Besides,

cube

textured

Y

2

0

3

films

were

obtained

in

far

narrower conditions

with

a

quite

low

energy

(150

eV)-ion bombardment

at

the

temperature

of

300

TC.

The

assisting

ion

energy

dependence was

discussed

in

connection

with lattice

energies

for

these

oxide

crystals.

INTRODUCTION

Biaxially

aligned

Yttria

Stabilized

Zirconia

(YSZ)

or

MgO

films formed

by

ion-beam-

assisted

deposition

(IBAD)

are

reliable

template

layers

for

Y-123

coated

conductors

[1-4].

However,

intercalation

of

thin

CeO

2

or

Y

2

0

3

layers

beneath

Y-123

film

is

still

effective

to

compensate

lattice

mismatch

and

prevent slight interdiffusion

[5].

It

is

worthy to

form

more

adequate

buffer

materials

directly

on alloy tapes by IBAD.

In

this

work,

the crystalline

alignment

properties were

studied

for

fluorite type

(Zro.

85

Yo.1501.93

(YSZ),

Hfo.

74

Ybo.

26

0

1

.

87

,

CeO

2

),

pyrochlore

type

(Zr

2

Sm

2

0

7

),

and

rare-earth

C

type

(Y

2

0

3

,

Sm203)

oxide

films.

Those

three

type

crystals have

quite

similar structures.

Fig.

1

shows

a

schematic

view

of

the

fluorite structure. Pyrochlore

and

rare-earth

C

structures

correspond

to

ones whose

1/8

and

1/4

of

oxygen

ions

deleted

from

fluorite

structure,

respectively.

Comparison

of

growth

properties

between

them

would

help

to

understand

the

peculiar

crystallization

of

the

IBAD

process,

whose

mechanism

has

been

poorly

understood

as

yet.

This paper

concentrates

on fluorite-like

type

oxides

formed

by

using

a

dual-ion-beam-

sputtering

method.

IBAD

is

characterized

to

conduct concurrent

ion

bombardment

during

film growth,

which

induces

biaxially textured

crystallization

[6].

It

is

natural

to

consider

lattice-bonding

strength,

which

affects

ion bombardment

effects

on

growing films.

The

fluorite-like

type

oxides

are

ionic

crystals,

and

their

lattice

bonding

energies

are

evaluated

by static

electricity

among

cations

and

oxygen

ions. Lattice energies should

decrease

with

fluorite,

pyrochlore,

and

rare-

Fig.

1.

Schematic drawing

for

structure

of

fluorite

type oxide.

cation

0

02

45

Mat.

Res.

Soc.

Symp.

Proc.

Vol.

585

©

2000

Materials

Research Society

Table

I.

Structural

properties

for

fluorite-like

type

oxides.

Lattice

type

fluorite

pyrochlore rare-earth

C

mean

valence

number

of

cations

4

-

3.74*

3.5

3

vacant

ratio

for

oxygen

site

0%

-

6.5%*

12.5%

25.0%

lattice

energy high

middle

low

*deviations

caused

by

addition

of

Y

2

0

3

or

Yb

2

0

3

for

structural

stabilization.

earth

C, as

summarized in

Table

I.

Several

fluorite

type oxides were

reported

to be

formed

with

biaxial texture

by

IBAD,

but

pyrochlore

or

rare

earth

C

ones

have

not

been

ever-reported

[7-8].

EXPERIMENTAL

Films

were formed

by

a

dual

ion

beam

sputtering

method,

as

shown

in

Fig.

2.

The

substrate

was

a

mirror-like

polished polycrystalline Ni-based

alloy

plate.

Sintered ceramics

of

5

inches

diameter

were

used

for

sputtering targets.

The

stoichiometry

for

YSZ,

HfO

2

-Yb

2

O

3

,

and

Zr

2

Sm

2

0

7

targets

were

ZrO

2

: Y

2

0

3

=

92

: 8,

HfO

2

:Yb

2

O

3

,=

85

:

15,

and

ZrO

2

:

Sm

2

03

=

2

: 1,

respectively.

5

cm

diameter

DC

ion

sources were

used

for

sputtering

and

ion

assisting.

The

assisting

ion beam

was an Ar+ or Kr+

beam

with

the

energy

below

300 eV. The

ion current

density

was

100-200 jtA/cm

2

.

Substrates

were set

on

a

holder

that

can have the desired

angle

to

the

assisting

beam

axis.

Substrate

temperature below

500

°C

was

controlled

by

a

thermocouple

on

a

dummy

plate

next

to

the samples. Oxygen

gas was

introduced

to

the

chamber

with

partial

pressure

of

1.OxI04

Torr.

The

deposition

time

was from

4

to

8

hours.

The

thicknesses

of

films

were

from

0.4

to

1.0

ýtm.

Growth structures

were

characterized

by

X-ray

diffraction

(XRD).

Fig.

2.

Schematic drawing

02

for

dual

ion

beam

Sputering

sputtering

system.

ion

r--rc

Target

Incident

siin

Inert

gas

angle

ion

source

Sample

1

Samnple~

Inert

gag

Heater

I]

Neutralizer

Inert

gas

RESULTS

&

DISCUSSION

Temperature

dependence of

alignment

axes

geometry

Biaxial alignment

of

an

off

normal

IBAD

process

is

characterized by two

crystalline

axes

simultaneously

fixed during

growth;

an

axis

aligned normal

to

the substrate,

and

another

axis

aligned

to

the

direction

of

the

incident

ions.

The

crystalline

alignment properties

are

summarized

in

Table

II.

Bold

letters indicate

"cube-texture",

which

must

be

held

by

effective

template

films

for

Y-

123

coated

conductors.

46

Table

II.

Alignment

axes for

buffer materials

by

IBAD.

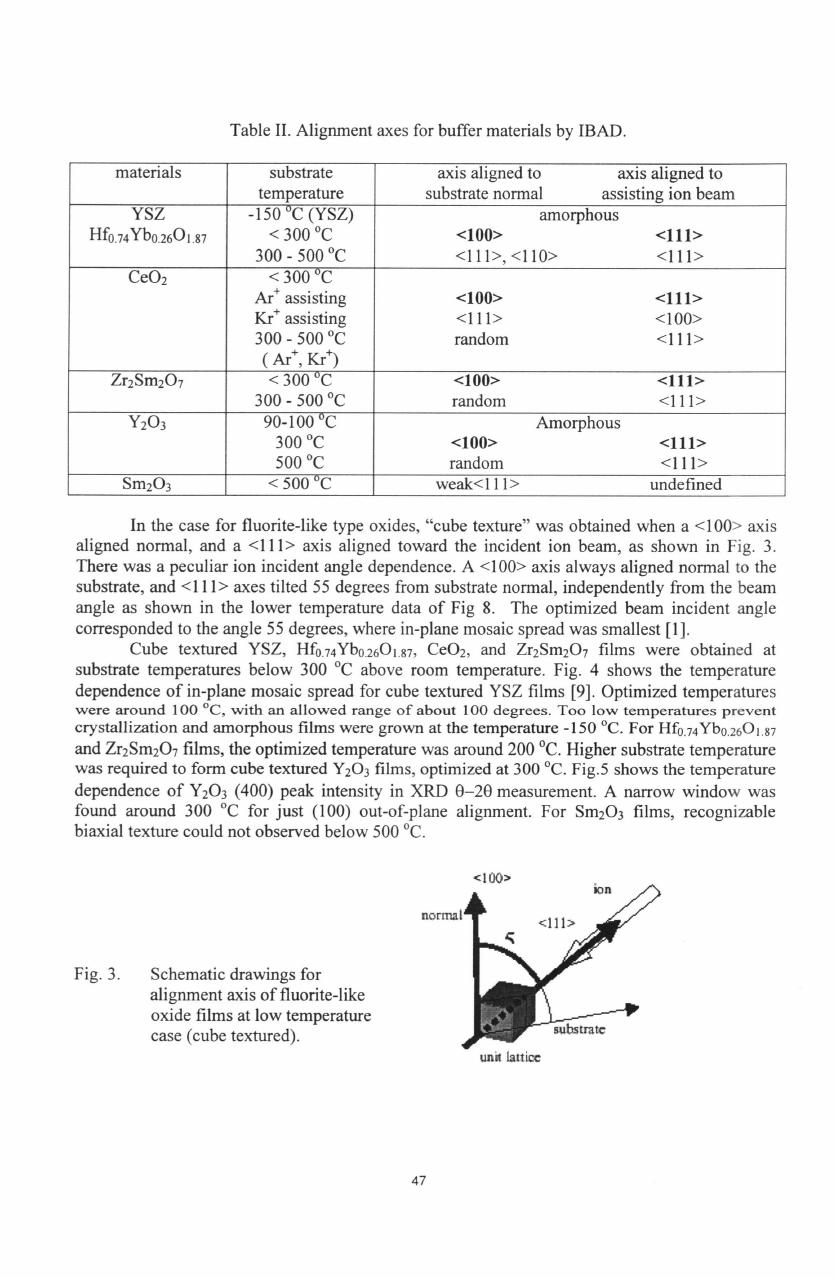

In

the

case for

fluorite-like

type

oxides,

"cube

texture" was

obtained

when

a

<100>

axis

aligned

normal,

and a

<111>

axis

aligned

toward

the

incident

ion beam,

as

shown

in

Fig.

3.

There

was

a

peculiar

ion

incident

angle dependence.

A

<100>

axis

always

aligned normal

to

the

substrate,

and

<111>

axes

tilted

55

degrees

from

substrate

normal,

independently

from

the

beam

angle

as

shown

in

the lower

temperature

data

of

Fig

8.

The

optimized

beam

incident

angle

corresponded

to

the

angle

55

degrees,

where

in-plane

mosaic

spread

was

smallest

[1

].

Cube

textured

YSZ,

Hf

0

.

74

Yb

0

.

26

O

1

.

87

,

CeO

2

,

and

Zr

2

Sm

2

0

7

films

were

obtained

at

substrate

temperatures

below

300

0

C

above

room

temperature.

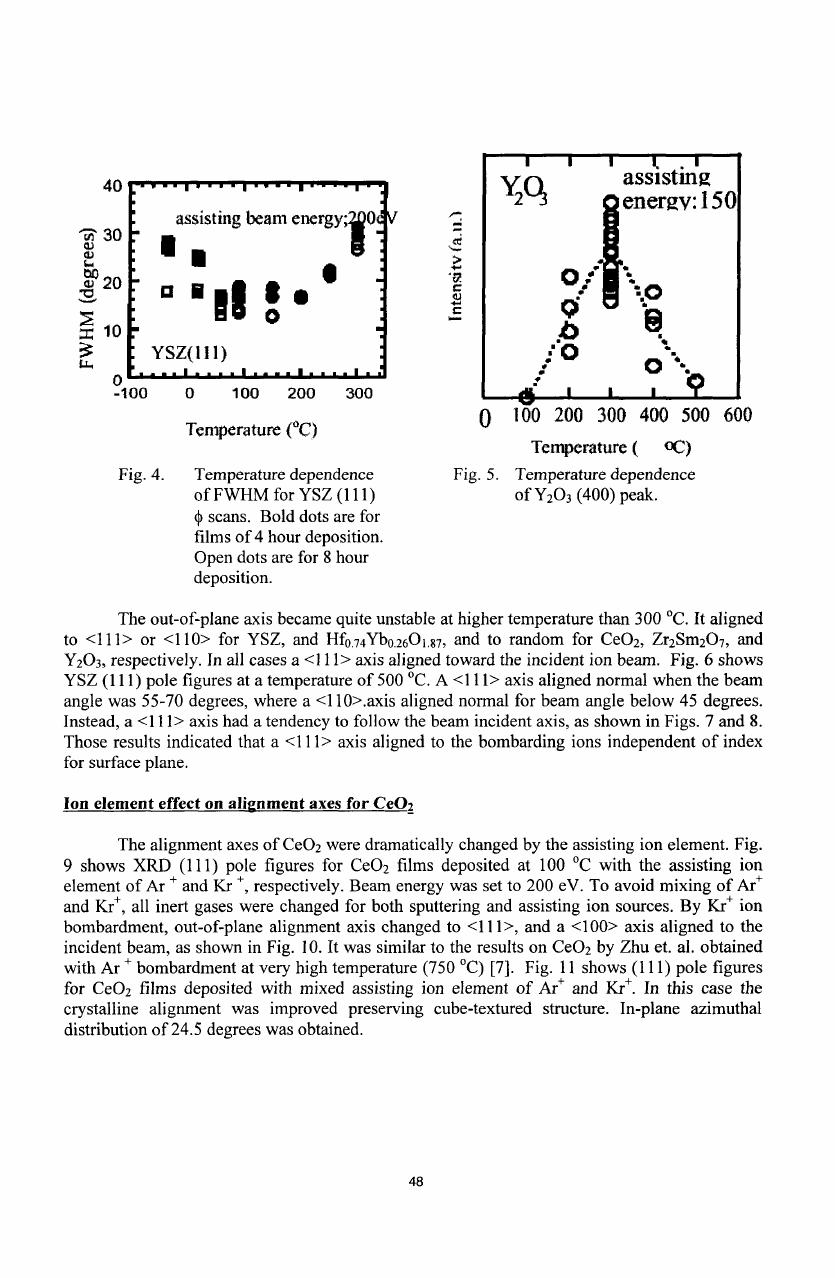

Fig.

4

shows

the

temperature

dependence

of

in-plane

mosaic

spread

for

cube

textured

YSZ

films

[9].

Optimized

temperatures

were

around

100

'C,

with

an

allowed

range

of

about

100

degrees.

Too

low

temperatures

prevent

crystallization

and

amorphous

films

were

grown

at

the

temperature

-150

°C.

For

Hf

0

.

74

Yb

0

.

26

0

1

.8

7

and

Zr

2

Sm

2

0

7

films,

the

optimized

temperature

was

around

200

0

C.

Higher

substrate

temperature

was

required

to

form

cube

textured

Y

2

0

3

films,

optimized

at

300

TC.

Fig.5

shows

the

temperature

dependence

of

Y

2

0

3

(400)

peak intensity

in

XRD

0-20

measurement.

A

narrow

window

was

found around

300

°C

for

just

(100)

out-of-plane

alignment.

For

Sm

2

0

3

films,

recognizable

biaxial

texture

could

not observed

below

500

°C.

<I00>

ion

normal

<111>

Fig.

3.

Schematic

drawings

for

alignment

axis

of

fluorite-like

oxide

films

at

low

temperature

case

(cube

textured).

,ubstrte

uni

lattice

47

materials

substrate

axis

aligned

to

axis

aligned

to

temperature

substrate

normal

assisting

ion

beam

YSZ

-150

°C

(YSZ)

amorphous

HfO.

74

Yb

0

.

26

0

1

.

87

<

300

°C

<100>

<111>

300-500

°C

<l1l>,<ll0>

<111>

CeO

2

<

300

°C

Ar+

assisting

<100>

<111>

Kr+ assisting

<111>

<100>

300

-

500

°C

random

<111>

(

Ark,

Kr+)

Zr

2

Sm

2

0

7

<

300

°C

<100>

<111>

300

-

500

°C

random

<111>

Y

2

0

3

90-100

°C

Amorphous

300

°C

<100>

<111>

500

°C

random

<111>

Sm

2

0

3

<

500

°C

weak<l

11>

undefined

40

'7

3

assisting

beam

energy;O

30 U

20

0

.0

0

z 0

YSZ(1

11)

p

o

4

100

0

100

200

300

1

I i

Temperature

(C)

100

200

300

400

500

600

Temperature

(

DC)

Fig.

4.

Temperature dependence

Fig.

5.

Temperature

dependence

of

FWHM

for

YSZ

(111)

of

Y

2

0

3

(400)

peak.

Sscans.

Bold

dots

are

for

films

of

4

hour deposition.

Open

dots

are

for

8

hour

deposition.

The

out-of-plane

axis

became

quite unstable

at

higher temperature than

300

TC.

It

aligned

to

<111>

or

<110>

for

YSZ,

and

Hf

0 74

Yb

026

O

1

.

87

,

and

to

random

for

CeO

2

,

Zr

2

Sm

2

0

7

,

and

Y

2

0

3

,

respectively.

In

all

cases

a

<111>

axis

aligned toward

the

incident

ion

beam.

Fig.

6

shows

YSZ

(111)

pole

figures

at

a

temperature

of

500

0

C.

A

<111>

axis

aligned

normal when

the

beam

angle

was

55-70

degrees,

where

a

<1

10>.axis

aligned normal for beam

angle

below

45

degrees.

Instead,

a

<111>

axis had

a

tendency

to

follow

the

beam

incident

axis,

as

shown in

Figs.

7

and

8.

Those

results indicated

that

a

<1I1>

axis

aligned

to

the

bombarding

ions

independent

of

index

for

surface

plane.

Ion

element

effect

on

alignment

axes

for

Ce0

2

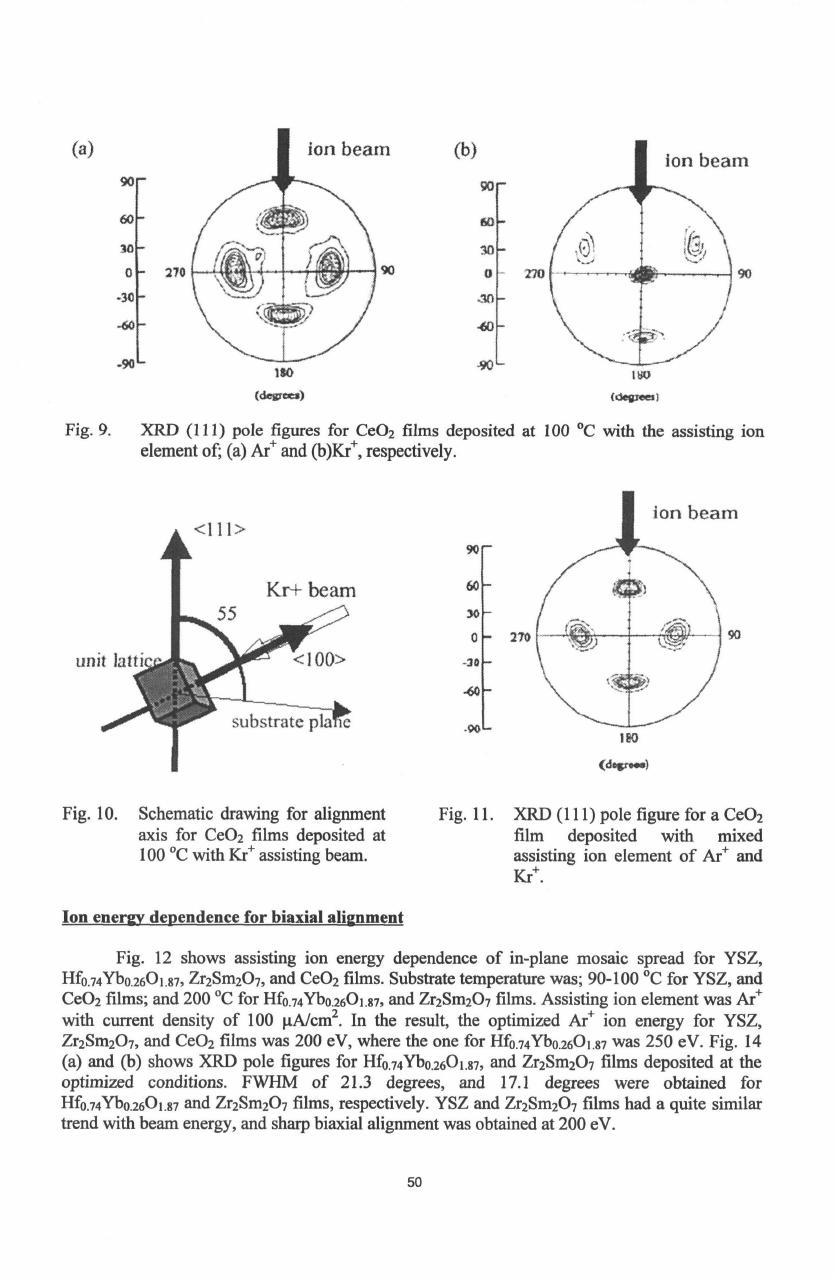

The

alignment

axes

of

CeO

2

were

dramatically changed

by

the

assisting ion

element.

Fig.

9

shows XRD

(111)

pole figures

for

CeO

2

films

deposited

at

100

TC

with the assisting

ion

element

of

Ar

+

and

Kr

+,

respectively. Beam

energy

was

set to

200

eV.

To

avoid

mixing

of

Ar+

and

Kr+,

all

inert

gases were changed

for

both sputtering

and

assisting ion

sources.

By

Kr+

ion

bombardment,

out-of-plane

alignment

axis

changed

to

<111>,

and

a

<100>

axis

aligned

to

the

incident

beam,

as

shown

in

Fig.

10.

It

was

similar

to the

results

on

CeO

2

by

Zhu

et.

al.

obtained

with Ar

+

bombardment

at

very

high temperature

(750

'C)

[7].

Fig.

11

shows

(111)

pole

figures

for

CeO

2

films

deposited

with mixed assisting

ion

element

of

Ar+

and

Kr+.

In

this case

the

crystalline alignment

was

improved preserving

cube-textured

structure.

In-plane

azimuthal

distribution

of

24.5

degrees was

obtained.

48

(a)

(b)

90

30

0

-30

-60

270

90

30

0

-30

-90

(4egrvwl

270

ISO

(depges)

Fig.

6.

YSZ

(111)

pole

figures

for

various

beam

incident angles

at

temperature

of

500

°C,

with

the

beam

incident

angle

of:

(a)

35

0,

and

(b)

55

0,

respectively.

<111

unit

<110>

ion

be

l

substrate

ptane

,i

C0

0

III

60>

40U

20

00

20

40

60

60

Beam

incident angle

(degree)

Fig.

7.

Schematic

drawing for alignment

axis

of

fluorite-like

oxide films

at

high temperature

case.

Fig.

8.

The

relationship

between

the angles

from

normal, for

the incident

ion

axis, and

a

corresponding

<111>

axis.

Bold dotted

line

indicates

where

a

<111>

axis aligned to

the

beam

axis.

49

--

----

X----

90

_

~5oo0_

a

<I11>

axis

I//•am

incident

angle

tI I

I I

(a)

(a)

90

60

30

0

-30

-60

270

-90'

(b)

90

30

-90L

)so

Fig.

9.

XRD

(111)

pole

figures

for

CeO

2

films

deposited

element

of;

(a)

Ar+

and

(b)Kr+,

respectively.

<111>

90•

60

30

0

-30

.60

-90

I

Fig.

10.

Schematic

drawing for alignment

axis

for

Ce0

2

films deposited

at

100

TC

with

Kr+ assisting

beam.

Ion

energy

dependence

for

biaxial

alienment

unit

270

90

at

100

°C

with the assisting

ion

ISO

(d~voes)

Fig.

11.

XRD

(111)

pole figure

for

a

CeO

2

film

deposited

with

mixed

assisting

ion

element

of

Ar+

and

Kr+.

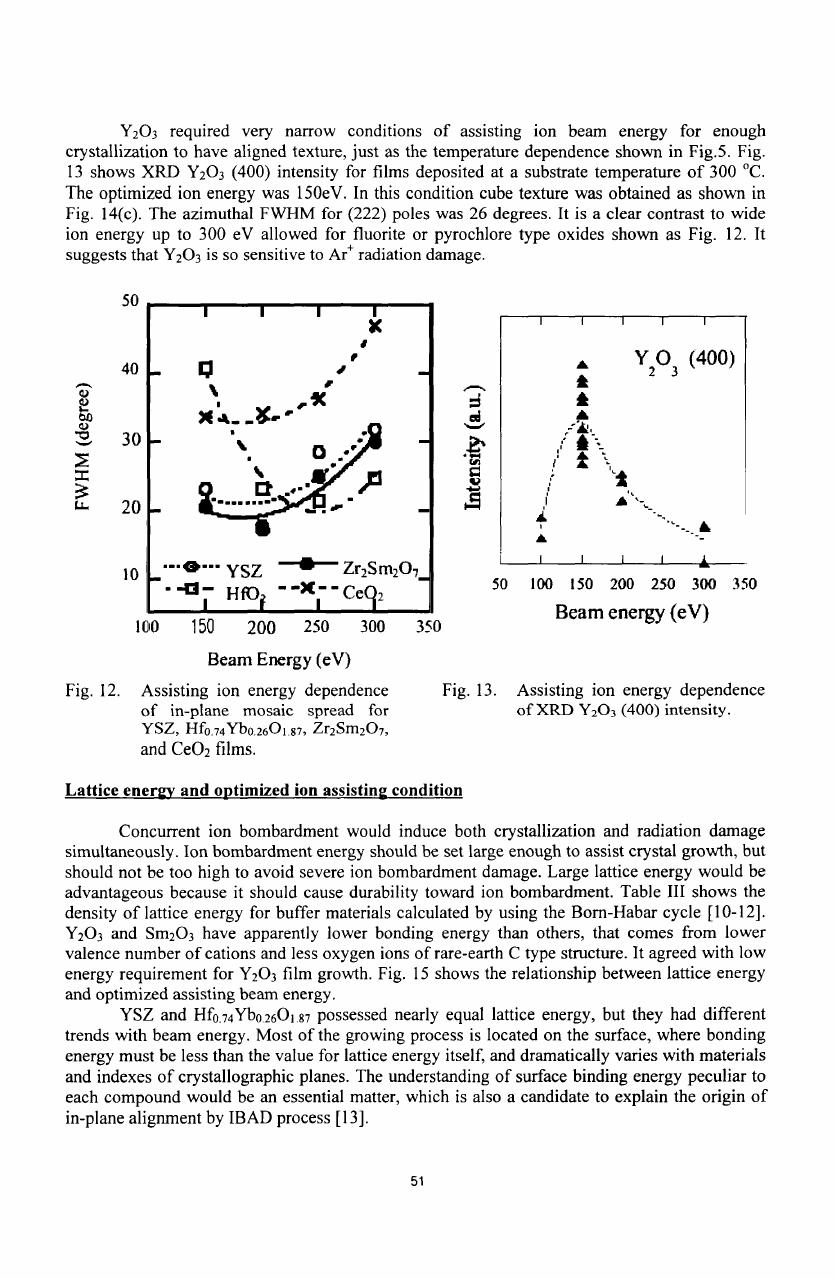

Fig.

12

shows

assisting

ion

energy

dependence

of

in-plane

mosaic

spread

for

YSZ,

Hfo.

74

Ybo.

26

0

1

.

87

,

Zr

2

Sm

2

0

7

,

and

CeO

2

films.

Substrate

temperature

was;

90-100

°C

for

YSZ,

and

CeO

2

films;

and

200

°C

for

Hfo.

74

Ybo.

2

6

0

1

.8

7

,

and

Zr

2

Sm

2

0

7

films.

Assisting

ion

element

was

Are

with current

density

of

100

pA/cm

2

.

In

the

result,

the

optimized

Ar

ion energy

for

YSZ,

Zr

2

Sm

2

0

7

,

and CeO

2

films

was

200

eV,

where

the

one

for

Hfo.

74

Ybo.

26

0

1

.

87

was

250 eV.

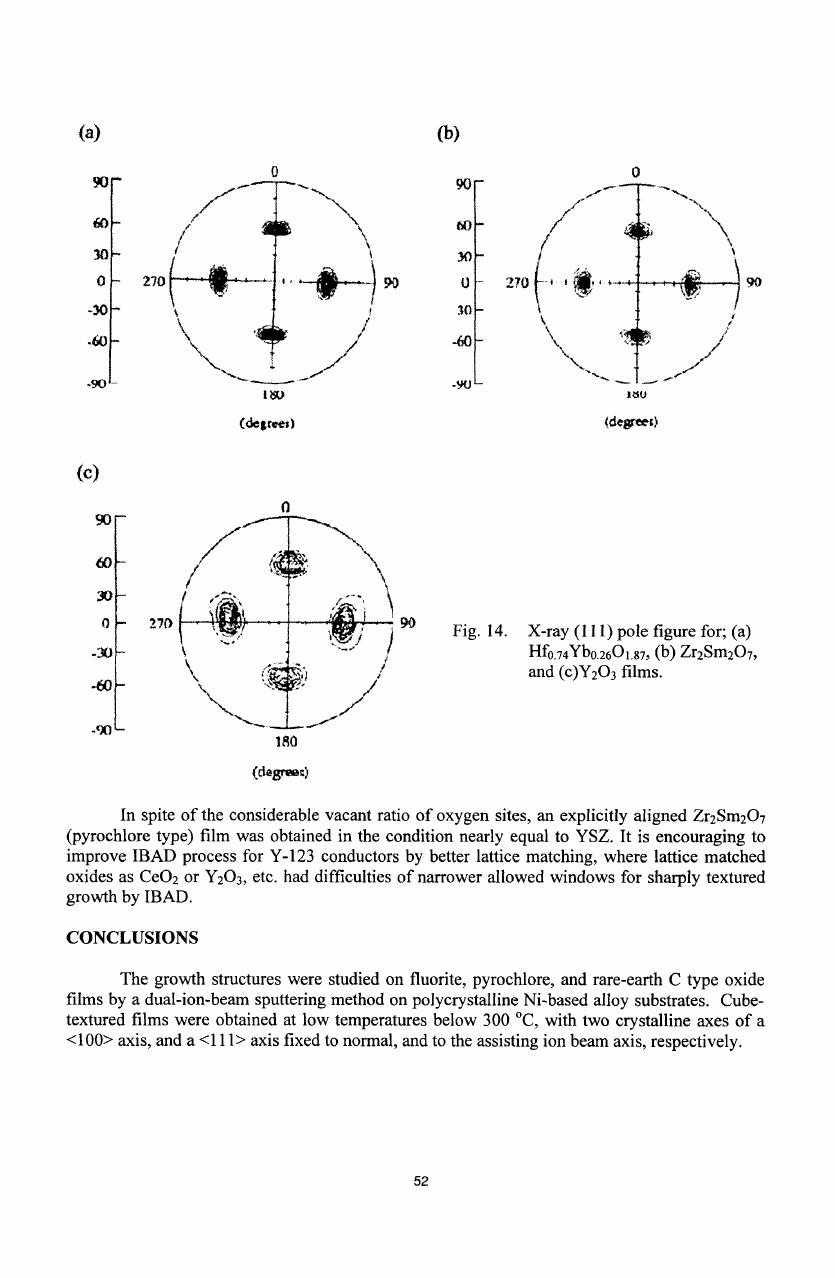

Fig.

14

(a) and

(b)

shows XRD

pole

figures

for

Hfo.

74

Ybo.

26

0

1

.

87

,

and

Zr

2

Sm

2

0

7

films

deposited

at

the

optimized

conditions. FWHM

of

21.3

degrees, and

17.1

degrees

were

obtained

for

Hfo.

74

Ybo.

26

0

1

.

87

and

Zr

2

Sm

2

0

7

films,

respectively. YSZ and

Zr

2

Sm

2

0

7

films

had

a

quite

similar

trend

with

beam

energy,

and sharp

biaxial

alignment

was

obtained

at

200

eV.

50

Y

2

0

3

required

very

narrow

conditions

of

assisting

ion

beam

energy

for

enough

crystallization

to

have

aligned texture,

just

as

the

temperature dependence

shown

in Fig.5.

Fig.

13

shows

XRD

Y

2

0

3

(400)

intensity

for

films

deposited

at

a

substrate

temperature

of

300

0

C.

The

optimized

ion energy

was

150eV. In

this

condition

cube

texture was

obtained

as

shown

in

Fig.

14(c).

The

azimuthal

FWHM

for (222)

poles was

26

degrees.

It

is

a

clear

contrast

to

wide

ion

energy

up

to

300

eV

allowed

for

fluorite or

pyrochlore

type oxides shown

as

Fig.

12.

It

suggests

that

Y

2

0

3

is

so

sensitive

to

Ar+

radiation

damage.

I I I I

K

I I I I

I

40

Y

2

Y

3

(400)

323

S

30

-. "

S

20

-'-

10

...

YSZ

-

Zr

2

Sm

2

O_

i i i I

--

HoIO

-_

-e

50

10

150

200

250

300

350

J

eg

Beam

energy

(eV)

100

150

200

250

300

350

Beam

Energy

(eV)

Fig.

12.

Assisting

ion

energy

dependence

Fig.

13.

Assisting

ion energy

dependence

of

in-plane

mosaic

spread

for

of

XRD

Y

2

0

3

(400)

intensity.

YSZ,

Hfo.

74

Ybo.

26

0

1

.87,

Zr

2

Sm

2

O

7

,

and

CeO

2

films.

Lattice

energy

and

optimized

ion

assisting

condition

Concurrent

ion

bombardment

would induce

both

crystallization

and

radiation

damage

simultaneously.

Ion

bombardment

energy

should

be set large

enough

to

assist

crystal

growth,

but

should not

be

too

high

to

avoid

severe ion

bombardment

damage.

Large lattice energy

would

be

advantageous

because

it

should

cause

durability toward

ion

bombardment.

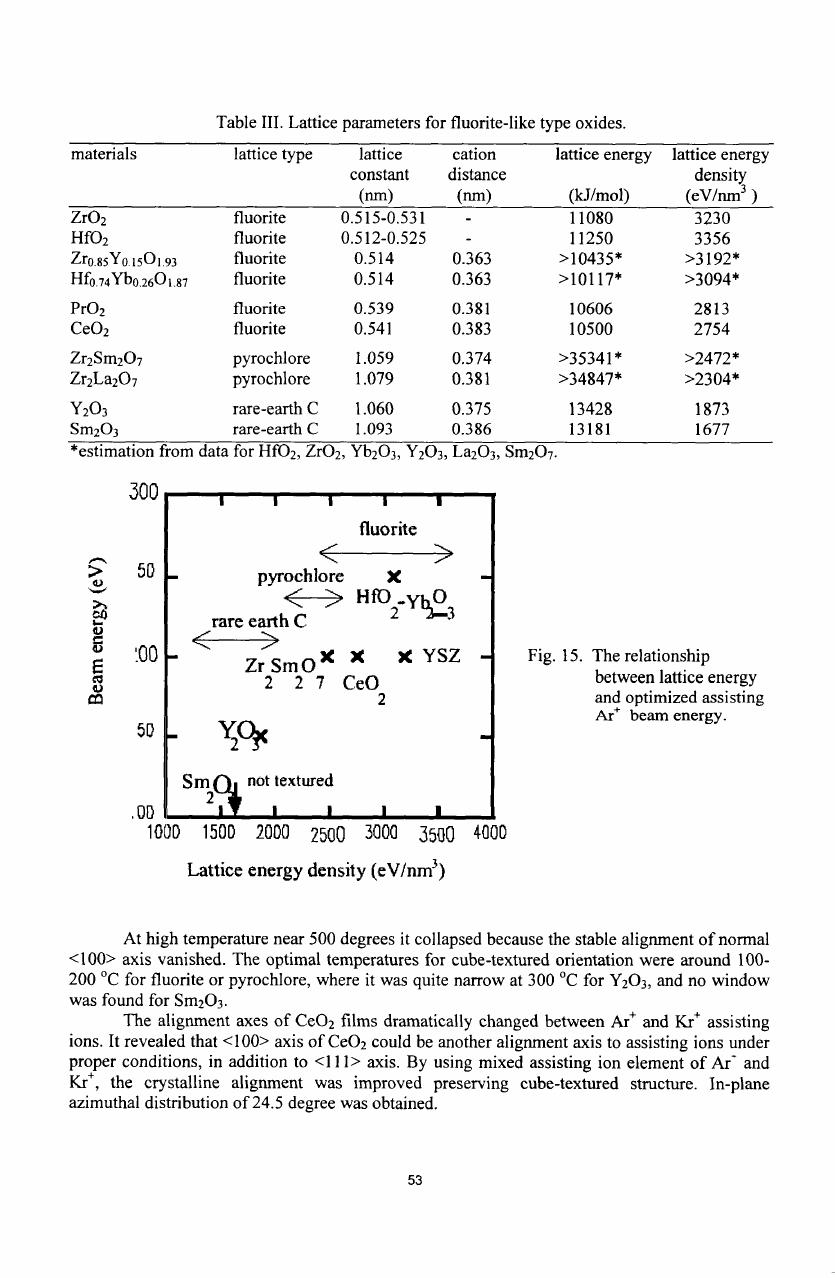

Table

III

shows

the

density

of

lattice energy

for

buffer

materials calculated

by

using

the

Bom-Habar

cycle

[10-12].

Y

2

0

3

and

Sm

2

0

3

have

apparently

lower

bonding

energy

than

others, that

comes

from lower

valence

number

of

cations

and

less

oxygen

ions

of

rare-earth

C

type

structure.

It

agreed with

low

energy

requirement

for

Y

2

0

3

film

growth. Fig.

15

shows

the

relationship

between

lattice

energy

and

optimized

assisting beam

energy.

YSZ

and

Hf

0

.

7

4

Yb

0

2601.87

possessed

nearly

equal

lattice

energy,

but they

had

different

trends with

beam

energy.

Most

of

the growing

process

is

located on the

surface,

where

bonding

energy

must

be

less

than

the

value

for

lattice

energy

itself,

and

dramatically

varies

with

materials

and

indexes

of

crystallographic

planes.

The

understanding

of

surface

binding

energy

peculiar

to

each

compound

would

be an

essential

matter,

which

is

also

a

candidate

to

explain

the

origin

of

in-plane

alignment

by

IBAD process

[13].

51

(a)

(b)

0

270

/ : ,/

(degree;)

270

0

jt

90

(0

30

0

30

-60

0

270

(A

I

90

-

K

/

(degreel

N

90

Fig.

14.

X-ray

(111)

pole

figure

for;

(a)

Hfo.

74

Yb

02

6

0

1

.

87

,

(b)

Zr

2

Sm

2

0

7

,

and

(c)Y

2

0

3

films.

-

iRO

(cdegreez)

In

spite

of

the

considerable

vacant ratio

of

oxygen

sites, an

explicitly aligned

Zr

2

Sm

2

0

7

(pyrochlore

type)

film

was

obtained

in

the

condition

nearly

equal

to

YSZ.

It

is

encouraging

to

improve

IBAD

process

for

Y-123

conductors

by

better

lattice

matching,

where lattice

matched

oxides

as

CeO

2

or

Y

2

0

3

,

etc.

had

difficulties

of

narrower

allowed windows

for sharply

textured

growth

by IBAD.

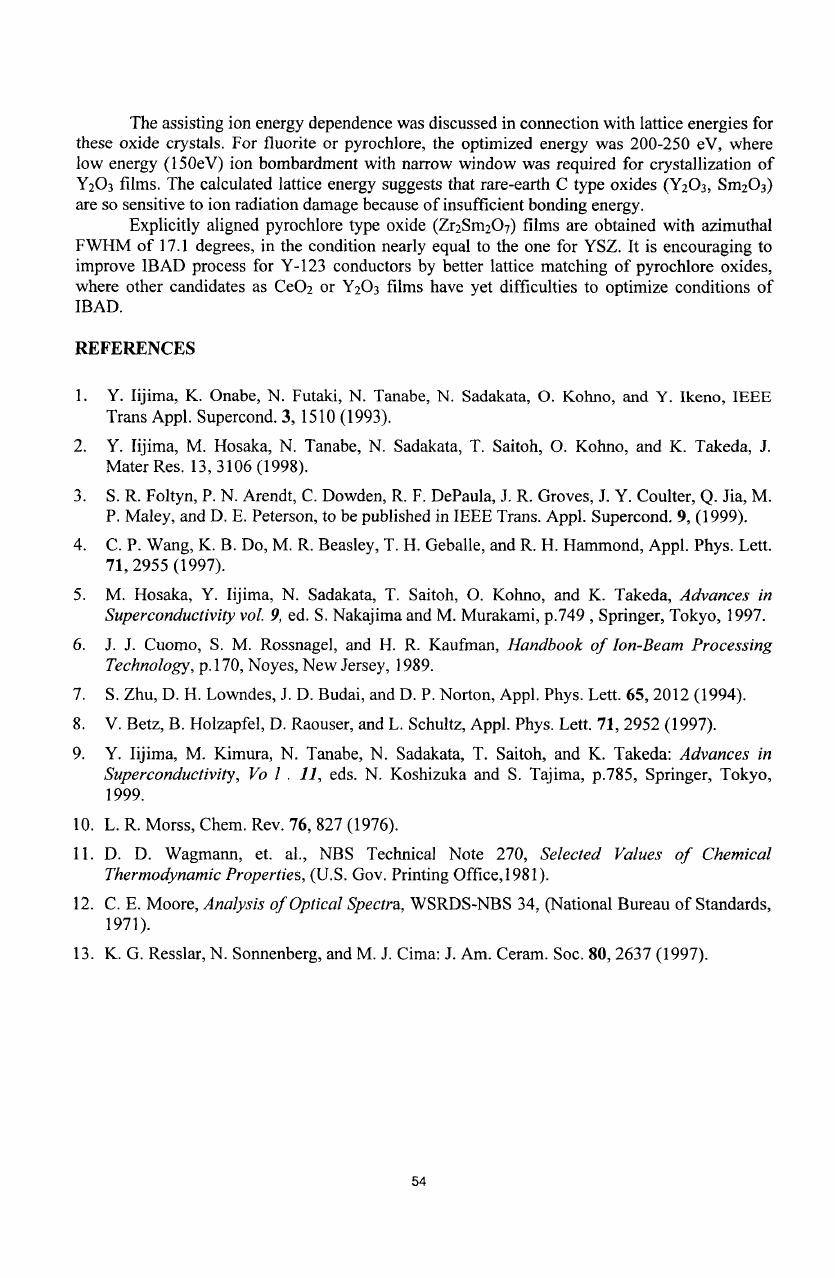

CONCLUSIONS

The

growth

structures

were

studied

on fluorite,

pyrochlore,

and

rare-earth

C

type

oxide

films

by

a

dual-ion-beam

sputtering

method

on

polycrystalline

Ni-based alloy

substrates.

Cube-

textured

films

were obtained

at

low

temperatures

below

300

"C,

with

two

crystalline

axes

of

a

<100> axis,

and

a

<111>

axis

fixed

to

normal, and

to the

assisting

ion beam

axis,

respectively.

52

90

60

30

0

-30

.60

-90,

(c)

90

60-

30-

-90-

•)

-9u

Table

III.

Lattice parameters for fluorite-like

type

oxides.

materials

lattice

type

lattice

cation

lattice

energy

lattice

energy

constant

distance

density

(nm)

(nm)

(kJ/mol)

(eV/nm

3

)

ZrO

2

fluorite

0.515-0.531

-

11080

3230

HfO

2

fluorite

0.512-0.525

-

11250

3356

Zr085Y01501.93

fluorite

0.514

0.363

>10435*

>3192*

Hf

0

.

74

Yb

026

O

1 8

7

fluorite

0.514

0.363

>10117*

>3094*

PrO

2

fluorite

0.539

0.381

10606

2813

CeO

2

fluorite

0.541

0.383

10500

2754

Zr

2

Sm

2

0

7

pyrochlore

1.059

0.374

>35341*

>2472*

Zr

2

La

2

O

7

pyrochlore

1.079

0.381

>34847*

>2304*

Y

2

0

3

rare-earth

C

1.060

0.375 13428

1873

Sm

2

0

3

rare-earth

C

1.093

0.386

13181

1677

*estimation

from

data

for

HfO

2

,

ZrO

2

,

Yb

2

0

3

, Y

2

0

3

,

La

2

0

3

, Sm

2

0

7

.

300

50

100

P-11I

1000

1500

2000

2500

3000

3500

Fig.

15.

The

relationship

between lattice

energy

and

optimized

assisting

Ar+ beam

energy.

4000

Lattice

energy

density

(eV/nm

3

)

At

high temperature

near

500

degrees

it

collapsed

because

the

stable

alignment

of

normal

<100> axis

vanished.

The

optimal temperatures

for cube-textured

orientation

were

around

100-

200

TC

for

fluorite

or

pyrochlore,

where

it

was

quite

narrow

at

300

TC

for

Y

2

0

3

,

and

no

window

was

found for

Sm

2

0

3

.

The

alignment

axes

of

CeO

2

films

dramatically

changed

between

Ar+ and

Kr+

assisting

ions.

It

revealed

that <100>

axis

of

CeO

2

could

be

another

alignment

axis

to

assisting

ions

under

proper conditions,

in

addition

to

<1I1>

axis.

By

using

mixed

assisting

ion

element

of

Ar-

and

Kr+,

the

crystalline

alignment

was

improved

preserving

cube-textured

structure.

In-plane

azimuthal

distribution

of

24.5

degree

was obtained.

53

Co

I-

fluorite

pyrochlore

X

<-

HfC

-i

2

rare

earth

C

.<

>z

X

X

YSZ

7

Zr

SmO

YS

2

2 7

CeO

2

Sn2O

not

textured

I2I I

The

assisting

ion

energy

dependence

was

discussed

in

connection with

lattice

energies

for

these

oxide crystals.

For

fluorite

or

pyrochlore,

the

optimized

energy

was

200-250

eV,

where

low

energy

(150eV)

ion

bombardment

with

narrow

window

was

required

for

crystallization

of

Y

2

0

3

films.

The

calculated

lattice

energy suggests

that rare-earth

C

type oxides

(Y

2

0

3

,

Sm

2

0

3

)

are

so

sensitive

to

ion

radiation

damage

because

of

insufficient

bonding

energy.

Explicitly

aligned

pyrochlore

type oxide

(Zr

2

Sm

2

O

7

)

films

are

obtained

with azimuthal

FWHM

of

17.1

degrees,

in

the

condition

nearly

equal

to

the

one for YSZ.

It

is

encouraging

to

improve

IBAD

process

for

Y-123

conductors

by

better

lattice

matching

of

pyrochlore oxides,

where

other

candidates

as

CeO

2

or

Y

2

0

3

films have yet

difficulties

to

optimize

conditions

of

IBAD.

REFERENCES

I.

Y.

lijima,

K.

Onabe,

N.

Futaki,

N.

Tanabe,

N.

Sadakata,

0.

Kohno,

and

Y.

Ikeno,

IEEE

Trans Appl. Supercond.

3,

1510

(1993).

2.

Y.

Iijima,

M.

Hosaka,

N.

Tanabe, N.

Sadakata,

T.

Saitoh,

0.

Kohno,

and

K.

Takeda,

J.

Mater

Res.

13,

3106

(1998).

3.

S.

R.

Foltyn,

P.

N.

Arendt,

C.

Dowden,

R.

F.

DePaula,

J.

R.

Groves,

J.

Y.

Coulter,

Q.

Jia,

M.

P.

Maley,

and

D.

E.

Peterson,

to be

published

in

IEEE Trans. Appl. Supercond.

9,

(1999).

4.

C. P.

Wang,

K.

B.

Do,

M.

R.

Beasley,

T.

H.

Geballe,

and R.

H.

Hammond,

Appl. Phys. Lett.

71,

2955

(1997).

5.

M.

Hosaka,

Y.

lijima,

N.

Sadakata,

T.

Saitoh,

0.

Kohno, and

K.

Takeda,

Advances

in

Superconductivity

vol.

9,

ed.

S.

Nakajima

and

M.

Murakami,

p.749,

Springer, Tokyo,

1997.

6.

J. J.

Cuomo,

S.

M.

Rossnagel,

and

H.

R.

Kaufman,

Handbook

of

Ion-Beam

Processing

Technology,

p.

170,

Noyes,

New

Jersey,

1989.

7.

S.

Zhu,

D.

H.

Lowndes,

J.

D.

Budai,

and

D.

P.

Norton,

Appl.

Phys.

Lett.

65,

2012

(1994).

8.

V.

Betz,

B.

Holzapfel,

D.

Raouser,

and

L.

Schultz,

Appl. Phys.

Lett.

71,

2952

(1997).

9.

Y.

lijima,

M.

Kimura,

N. Tanabe,

N.

Sadakata,

T.

Saitoh,

and

K.

Takeda:

Advances

in

Superconductivity,

Vo

I .

11,

eds.

N.

Koshizuka

and

S.

Tajima,

p.785,

Springer,

Tokyo,

1999.

10.

L.

R.

Morss,

Chem.

Rev.

76, 827

(1976).

11.

D.

D.

Wagmann,

et.

al.,

NBS

Technical

Note 270,

Selected

Values

of

Chemical

Thermodynamic

Properties,

(U.S.

Gov.

Printing

Office,

1981).

12.

C.

E.

Moore,

Analysis

of

Optical

Spectra,

WSRDS-NBS

34,

(National

Bureau

of

Standards,

1971).

13.

K.

G.

Resslar,

N.

Sonnenberg,

and M.

J.

Cima:

J.

Am. Ceram.

Soc.

80,

2637

(1997).

54