Reliability and Performance of Pseudomorphic Ultraviolet Light Emitting Diodes on Bulk

Aluminum Nitride Substrates

James R. Grandusky

1

, Yongjie Cui

1

, Mark C. Mendrick

1

, Shawn Gibb

1

, and Leo J. Schowalter

1

Crystal IS, 70 Cohoes Avenue, Green Island, NY 12183, U.S.A.

ABSTRACT

Reliability and performance of ultraviolet light emitting diodes have suffered due to the high

dislocation density of the AlN and high Al-content Al

x

Ga

1-x

N layers when grown on foreign

substrates such as sapphire. The development of pseudomorphic layers on low dislocation

density AlN substrates is leading to improvements in reliability and performance of devices

operating in the ultraviolet-C (UVC) range. One major improvement is the ability to operate

devices at much higher current densities and input powers than devices on sapphire substrates.

This is due to the better thermal properties and lower dislocation density of devices on AlN

substrates. Devices with active area of 0.001 cm

2

emitting at ~265 nm have been measured for

their reliability and change in power output over time at input currents of 20 mA (20 A/cm

2

), 100

mA (100A/cm

2

) and 150 mA (150 A/cm

2

). When operating at currents of 20 mA over 3500

hours of consecutive operation has been demonstrated with typical decay of ~27% over the 3500

hours. Extrapolating the decay with a linear fit gives a L50 (time to 50% of initial power) of

~5000 hrs. However it is desirable to be able to model the decay to better understand the

kinetics and better understand the mechanisms. In order to do this, the lifetime at 20 mA and

100 mA were modeled using an exponential decay function, square root transformation and a log

transformation to both be able to fit the experimental data and predict future performance.

INTRODUCTION

Ultraviolet disinfection is becoming very important as an efficient means of providing

disinfection to water, air and surfaces without the use of chemicals. This requires a light source

that is emitting in the ultraviolet-C (UVC) range (<300 nm) for efficient disinfection due to a

peak in DNA absorption at ~ 265 nm

1

. Traditionally, mercury lamps are used, however these

suffer the disadvantages of short lifetimes, slow start up, and the use of toxic mercury which can

be a hazard if the bulb is broken and leads to problems with disposal. Light emitting diodes

(LEDs) have the capability of high efficiencies, fast start up which can be synchronized with

water flow, long lifetimes, variable wavelengths, and no toxic materials.

However, currently devices are fabricated from Al

x

Ga

1-x

N layers on sapphire substrates

which lead to a high dislocation density and thus low efficiencies and short lifetimes

2

. Bulk AlN

substrates offer several advantages over growth on sapphire, including low lattice and thermal

mismatch between the substrate and the device layers. In addition, pseudomorphic growth of

Al

x

Ga

1-x

N with x>0.6 can be obtained resulting in device layers with low dislocation densities,

low resistivities, and atomically smooth surfaces

3

.

Mater. Res. Soc. Symp. Proc. Vol. 1195 © 2010 Materials Research Society 1195-B03-04

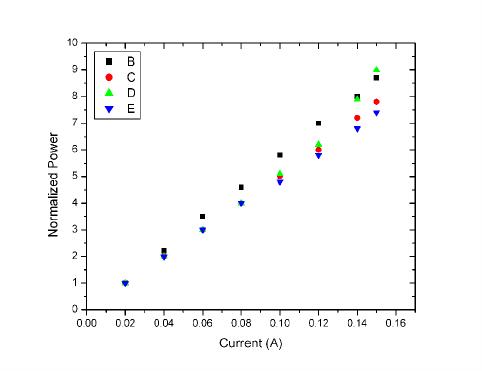

Figure 1. Performance of pseudomorphic UVC LEDs on bulk AlN substrates when driven to

high currents for 4 different devices. The Y axis (output power) is normalized to 20 mA and

shows linear increase in output power up to 150 mA drive current.

EXPERIMENT

Epitaxial growth was carried out as discussed previously

3

. The device structure consisted of

an n-type Al

x

Ga

1-x

N layer, a 5 period multiple quantum well, an electron blocking layer, and a p-

type GaN contact layer. Devices were processed using standard LED processing with a mesa

diameter of 350 µm. The devices are flip chip mounted to an AlN submount and packaged in

TO-8 and surface-mounted design (SMD) packages.

For testing of the diodes, the packaged devices were mounted on a pin fin anodized Al heat

sink (40 mm x 40 mm) with forced convection cooling which had an experimentally validated

theoretical thermal resistance of 2.5

o

C/W. With an applied forward bias, the output power was

measured in a calibrated integrating sphere. For lifetime measurements a photodiode was used

to measure the output power of each device.

DISCUSSION

Initial measurements were carried out on the devices at different input currents from 20 mA

to 150 mA. At each step, the system (device and heat sink) was allowed to achieve thermal

equilibrium and the output power was stable. The output power was then normalized to the

power at 20 mA and plotted versus forward current as shown in figure 1. In each device, the

increase in power at currents up to 150 mA is linear with no roll off or thermal effects. The

forward voltage of the devices is quite high and typically 20 V at 150 mA forward current

resulting in an input power of 3 W. The forward voltage is expected to become lower as the n

and p contact metallization is improved.

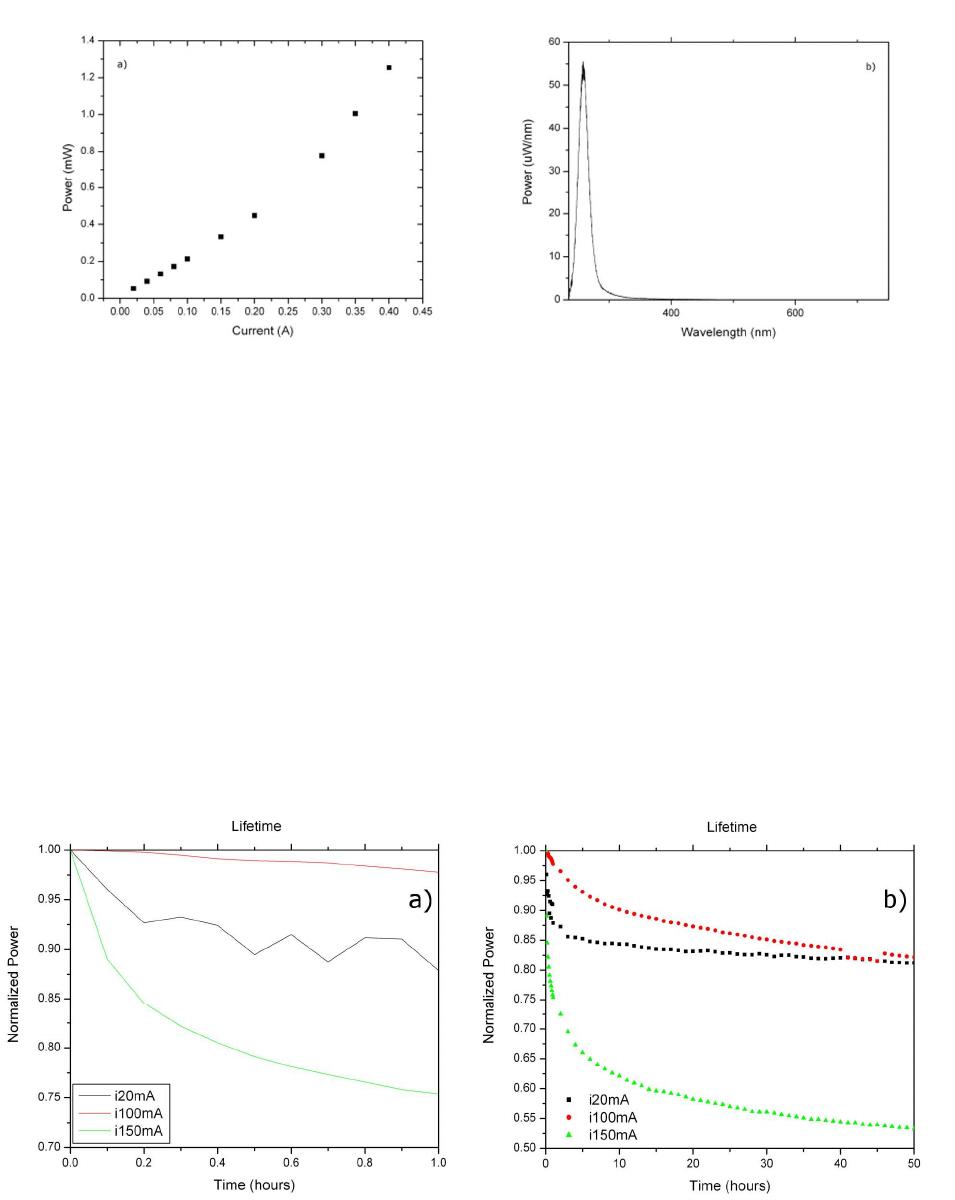

In order to test the potential of the devices at elevated currents, devices were tested at

currents greater than 150 mA without letting the device reach thermal equilibrium (quasi-cw).

figure 2 shows the results with an output power of 1.3 mW at 400 mA of current with a peak

wavelength of 258 nm.

Figure 2. Performance of pseudomorphic UVC LEDs on bulk AlN substrates when driven to a

forward current of 400 mA. The inset shows the spectra of the device at 400 mA with a peak

wavelength of 258 nm.

In addition to improved performance of the devices, an important feature of the

pseudomorphic LEDs is the reliability. It is expected that the low dislocation density in the

substrates will lead to increased reliability and increased lifetimes over devices fabricated on

sapphire substrates. Lifetime measurements were carried out at input currents of 20 mA, 100

mA, and 150 mA. For measurements at 20 mA no heat sinking was used and the devices were

suspended in air. However for higher currents, such as 100 and 150 mA, power inputs of up to 3

W necessitated the use of a heat sink.

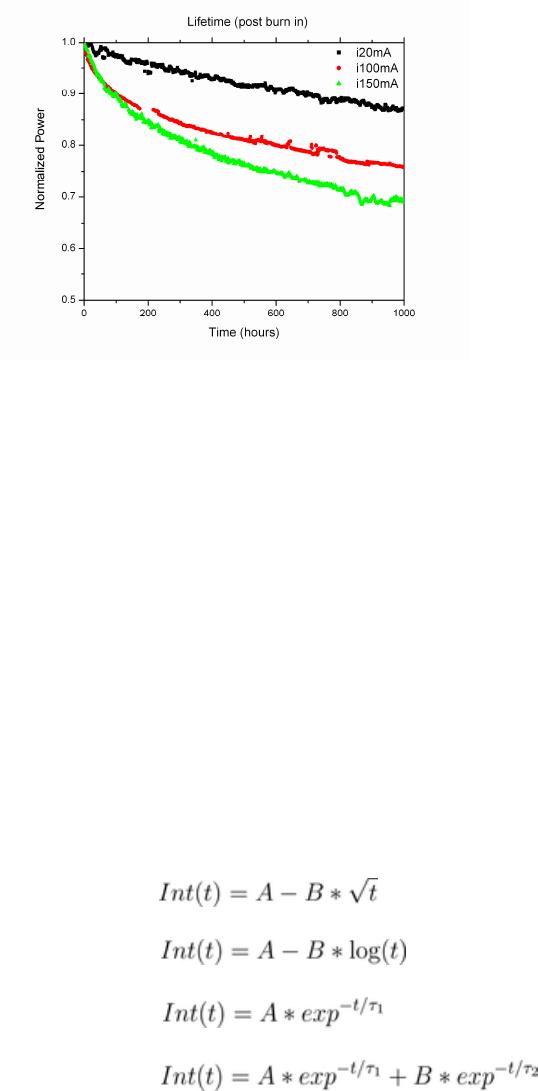

Reliability measurement at each current showed three distinct mechanisms for power decay.

The first mechanism was temperature related and due to the device reaching thermal equilibrium.

This was reversible, i.e. if the device was turned off and allowed to cool the power would

initially recover, followed by a rapid drop until thermal equilibrium was reached. This

degradation is shown in Figure 3a. For the 20 mA case, the power drops fast initially due to the

Figure 3. Power decay during the a) first hour of testing and b) first 50 hours for different drive

currents.

Figure 4. Power decay during the first 1000 hours of testing for different drive currents.

fact that there is no external heat sinking of the devices. For 100 mA very little heating is

observed due to the adequate heat sinking for the power input. At 150 mA however there is a

considerable rise in junction temperature leading to severe power decay in the first several

minutes of operation. The second decay mechanism is burn in, shown in figure 3b. It is unclear

exactly what the mechanism of this decay is, but it could be related to impurity diffusion in the

material

4

or further alloying of the contacts. When run in pulsed mode with low duty cycle the

decay is much slower indicating a stronger dependence on junction temperature as opposed to

current density.

After burn in there is a slow decay in power over time. The power decay is faster for higher

currents as expected, but it is unclear if this is thermally related or current density related. This

decay is shown in figure 4. As the decay is relatively slow, it becomes important to be able to

predict the lifetime of devices based on as little experimental data as possible. In order to do

this, devices were allowed to operate at 20 mA for 3500 hours and at 100 mA for 2000 hours.

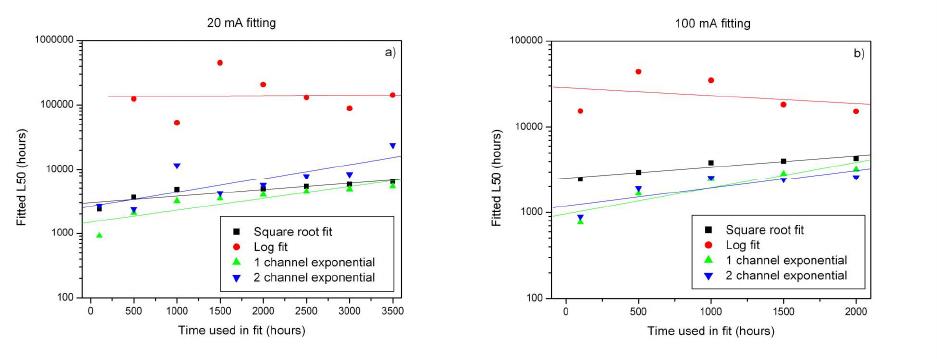

The data from 100, 500, 1000, 1500, 2000, 2500, and 3000 hours was fitted and used to predict

the L50 of the devices at each step. Figure 5 shows the fitted L50 for devices operated at 20 mA

and 100 mA as a function of time fitted by the following functions:

(1) Square root

(2) Logarithmic

(3) One channel exponential decay

(4) Two channel exponential decay

The two channel exponential decay and the square root fit are able to accurately fit the data

with R

2

values of 0.98 while the log fit shows a very good fit for the 100 mA data with a R

2

of

0.98 but a value of 0.92 for the 20 mA data. This is believed to be due to the lack of heat sinking

of the devices operated at 20 mA and the rapid initial drop. The one channel exponential decay

has the worst fit for both cases with R

2

values of 0.86 and 0.75 for the 20 mA and 100 mA cases

respectively. However, looking at the fitted values of L50, the predicted lifetime continues to

Figure 5. Fitted L50 as a function of time used in fit for 4 different models at a) 20 mA and b)

100 mA.

increase for the fits using the square root and exponential decay functions. However for the log

fit the value of L50 predicted after a short time is similar to the predicted value after a long time.

It appears that fitting the data to a log fit after only a few days worth of data gives the best

method of estimating the L50 with limited data; however we are continuing to collect data and

analyze the fitting functions to determine the best way to predict the L50.

The exponential

5

and square root

6

fits are typically used in the fitting of LED

degradation, and are able to provide adequate fits to the data here, but are not good at predicting

the lifetime. The reason for the breakdown in the prediction using the exponential functions is

due to the fact that this function is forced to go to zero and thus typically underestimates the

lifetime. This can be solved by adding a constant to the fit which will improve the fit of the data,

however this constant is not helpful in estimating the lifetime of the device (since it makes the

lifetime infinite). The logarithm fit has been used for modeling hot carrier injection and

electromigration in electronic devices and used to predict the lifetime of the devices over several

orders of magnitude with as short a measurement time as possible

7

. While hot carrier injection is

not relevant to light emitting diodes, the method of predicting lifetimes is similar and attempts to

relate this to a physical process in the material is currently underway.

CONCLUSIONS

The use of pseudomorphic layers grown on bulk AlN substrates has lead to the improved

performance and reliability of UVC LEDs. In addition to the improved performance at high

current densities, device reliability is much improved over devices grown on foreign substrates.

Devices have currently been operating for 3500 hours at 20 mA and 2000 hours at 100 mA

without reaching L50 and are currently still operating. This has lead to an effort to be able to fit

the decay of the power and be able to accurately predict the L50 value with as little data as

possible. The data was fitted to square root, logarithmic, and one and two channel exponential

decay functions to obtain the best function to predict the L50 values with a limited amount of

measured data. The logarithmic function was chosen as the best based on the current predictions

as the other fits continue to predict longer L50 values as more data is collected. With as little as

100 hours of data the logarithmic fit obtains similar values as to that obtain after 2000 hours at

100 mA. More data is currently being collected and analyzed to further validate this after the

devices reach their L50 values.

ACKNOWLEDGMENTS

This work was partially supported by an ATP grant (administered by NIST).

REFERENCES

1. EPA Document # 815-D-03-007

2. A. Khan, S. Hwang, J. Lowder, V. Advirahan, and Q. Fareed, Reliability Physics Symposium,

2009 IEEE International, 89, (2009).

3. J. R. Grandusky, J. A. Smart, M. C. Mendrick, L. J. Schowalter, K. X. Chen, and E. F.

Schubert, J. Cryst. Growth 311, 2864 (2009).

4. C.G. Moe et al. Reliability Physics Symposium, 2009 IEEE International, 94 (2009).

5. O. Ueda, 1996 “Reliability and Degradation of III-V Optical Devices” Artech House, Inc.

Norwood, MA, pgs. 279-281.

6. S. Sawyer, S. L. Rumyantsev, M. S. Shur, Solid State Electronics 52, 968, (2008).

7. Keithley Instruments Inc., HCI White Paper, (2001).